Optical readout gallium nitride group single quantum trap ultrasonic sensor

A gallium nitride monolithic and optical readout technology, applied in instruments, fluorescence/phosphorescence, analytical materials, etc., can solve problems such as unfavorable detection, large volume, and affecting detection and measurement accuracy, and achieve improved accuracy, light volume, and response time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

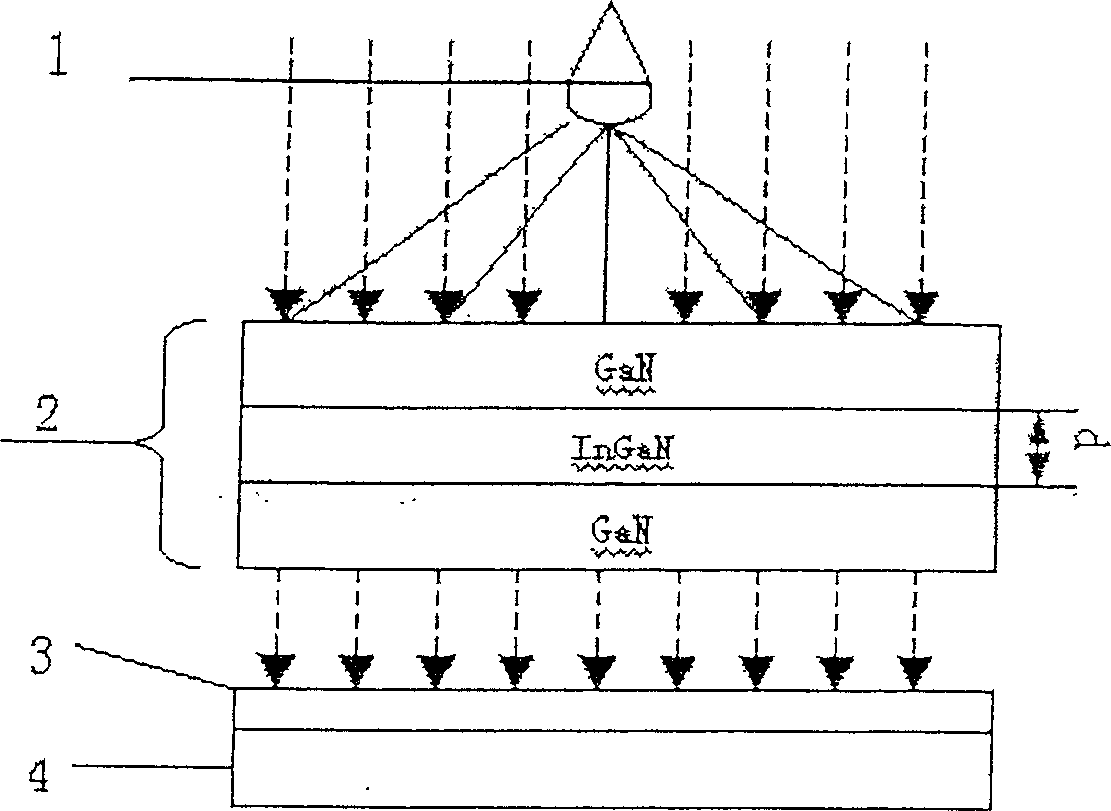

[0018] Taking the GaN / InGaN / GaN single quantum well ultrasonic sensor as an example below, the specific implementation of the present invention will be further described in detail in conjunction with the accompanying drawings:

[0019] See figure 1 , the ultrasonic sensor of the present invention consists of an auxiliary light source 1, a gallium nitride-based single quantum well 2, a narrow-band filter 3 and a Si photoelectric tube 4.

[0020] The auxiliary light source 1 uses a blue light tube for InGaN, and the narrow-band filter 3 depends on the wavelength band selected in this embodiment.

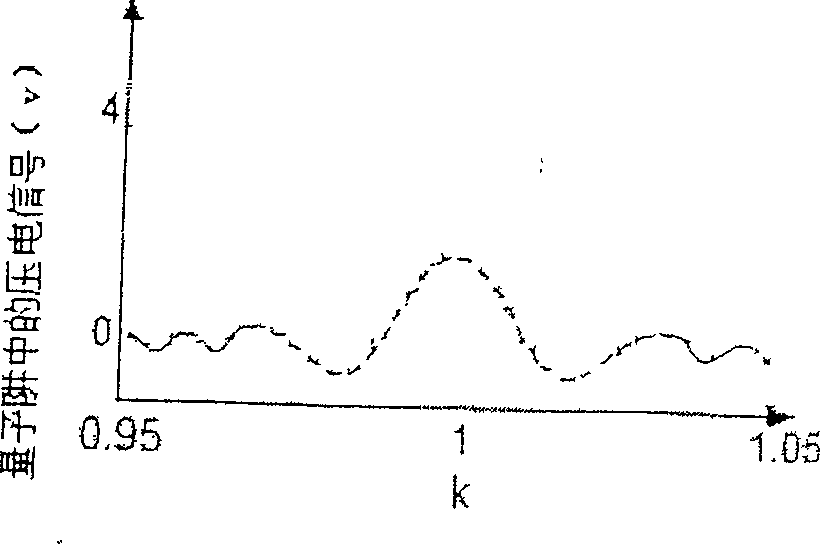

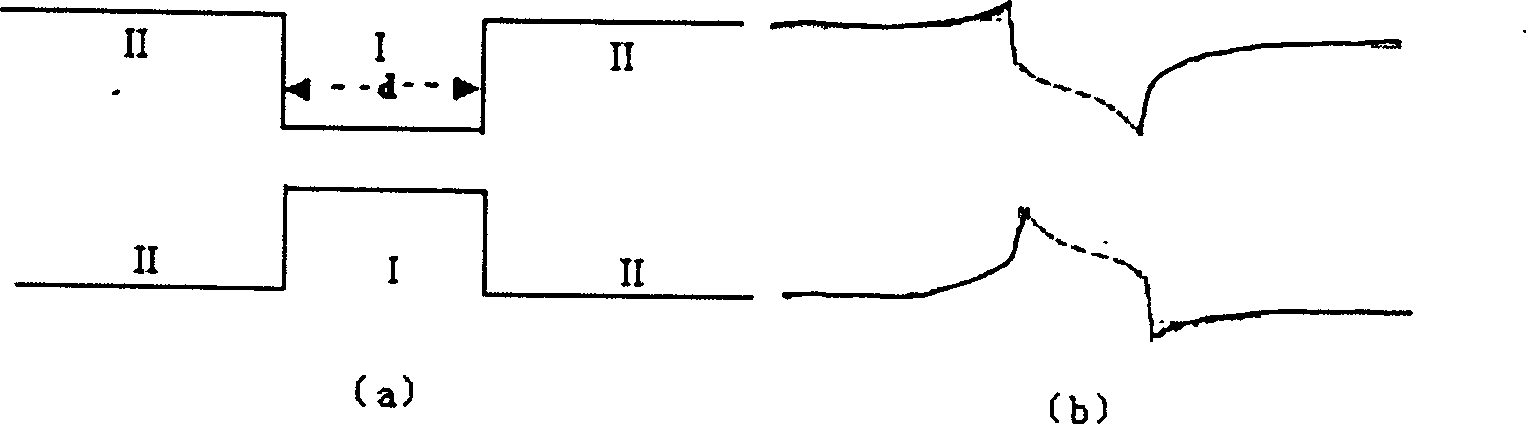

[0021] GaN single quantum well 2 is grown GaN layer, InGaN layer and GaN layer sequentially on the sapphire substrate by molecular beam epitaxy technology. The thickness of the InGaN layer is related to the wavelength of the ultrasonic wave it detects, because when the ultrasonic wave propagates in this material, it will be reflected and refracted by the interface in the quantum well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com