Method for mfg. overcurrent protection component

A technology for protecting components and manufacturing methods, which is applied in the direction of resistance manufacturing, electrical components, and current-responsive resistors, etc., to achieve the effects of reducing heating, reducing deformation and stress, and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Structural features of the present invention are described in detail as follows in conjunction with accompanying drawing and embodiment:

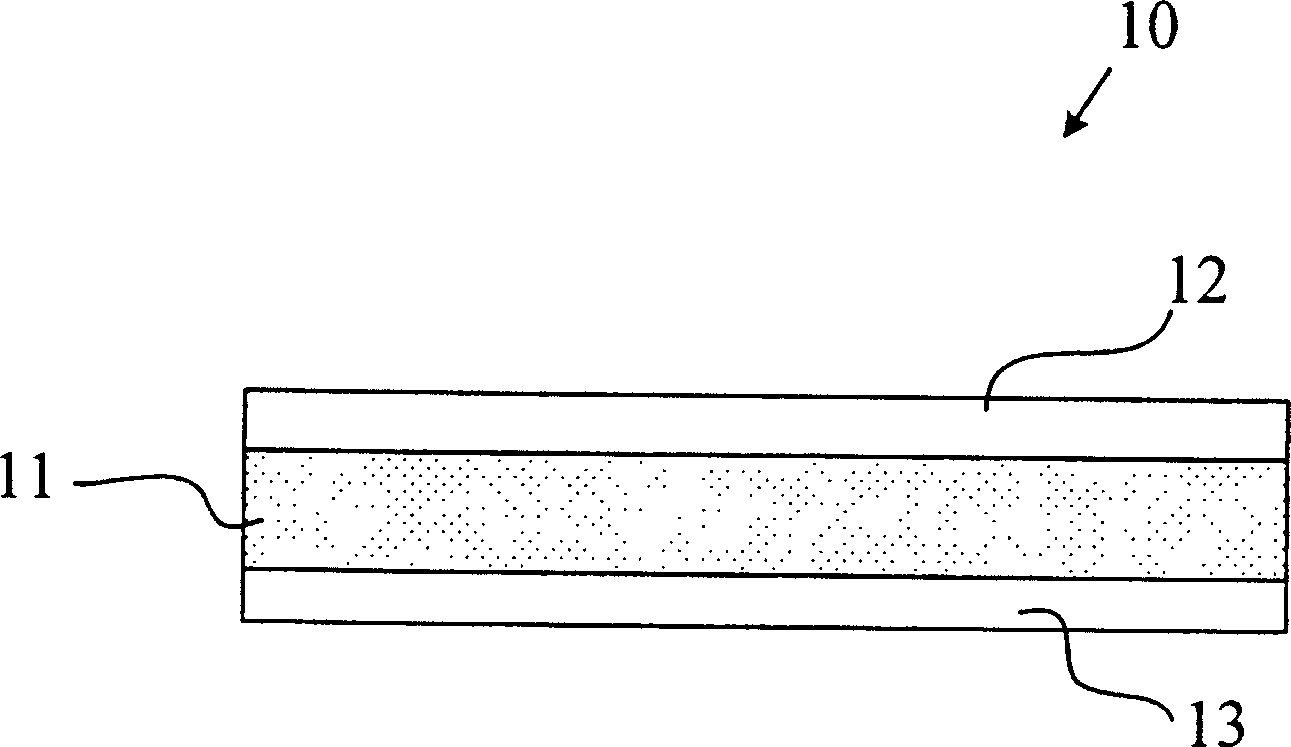

[0026] like figure 1 As shown, the overcurrent protection element 10 includes: a current sensing element 11 , an upper electrode foil 12 and a lower electrode foil 13 . The current sensing element 11 is made of conductive composite material with positive temperature coefficient (PTC), including at least polymer and conductive filler. The upper electrode foil 12 and the lower electrode foil 13 are pasted on two sides of the current sensing element 11 .

[0027] The polymer used to prepare the PTC conductive composite material includes at least one crystalline or non-crystalline polymer, such as polyethylene, polypropylene, polyoctene and mixtures thereof.

[0028] The conductive filler is dispersed in the polymer and is selected from the group consisting of carbon black, metal particles, graphite, ceramic powder and mixtures thereof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com