Compound damping board and its manufacturing method

A compound damping and damping technology, applied in chemical instruments and methods, superstructure sub-assemblies, layered products, etc., can solve the problems of sound insulation, poor shock absorption, harsh preparation conditions, and high production costs, and achieves the goal of using less equipment. , the effect of low manufacturing cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

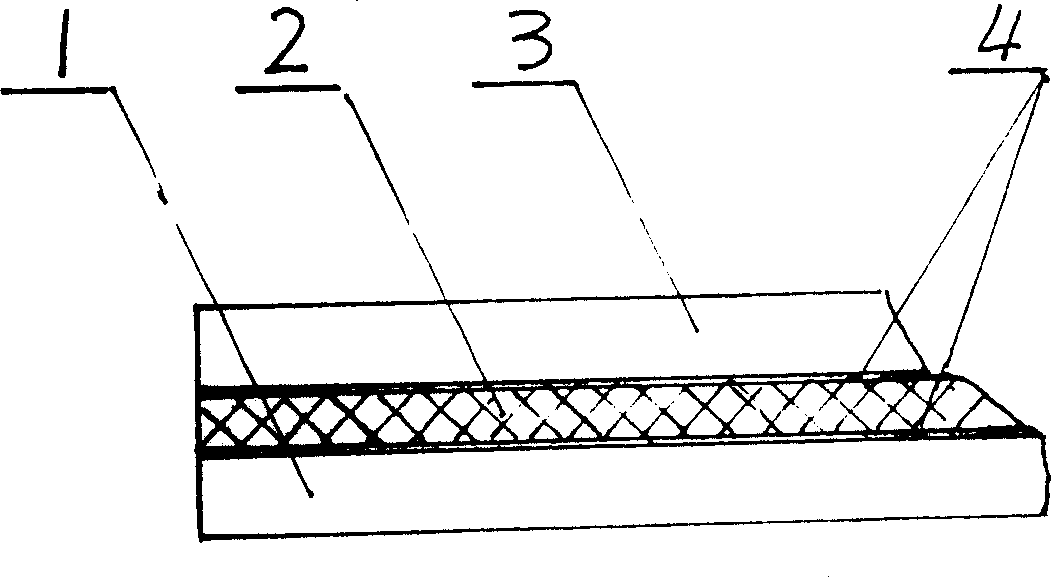

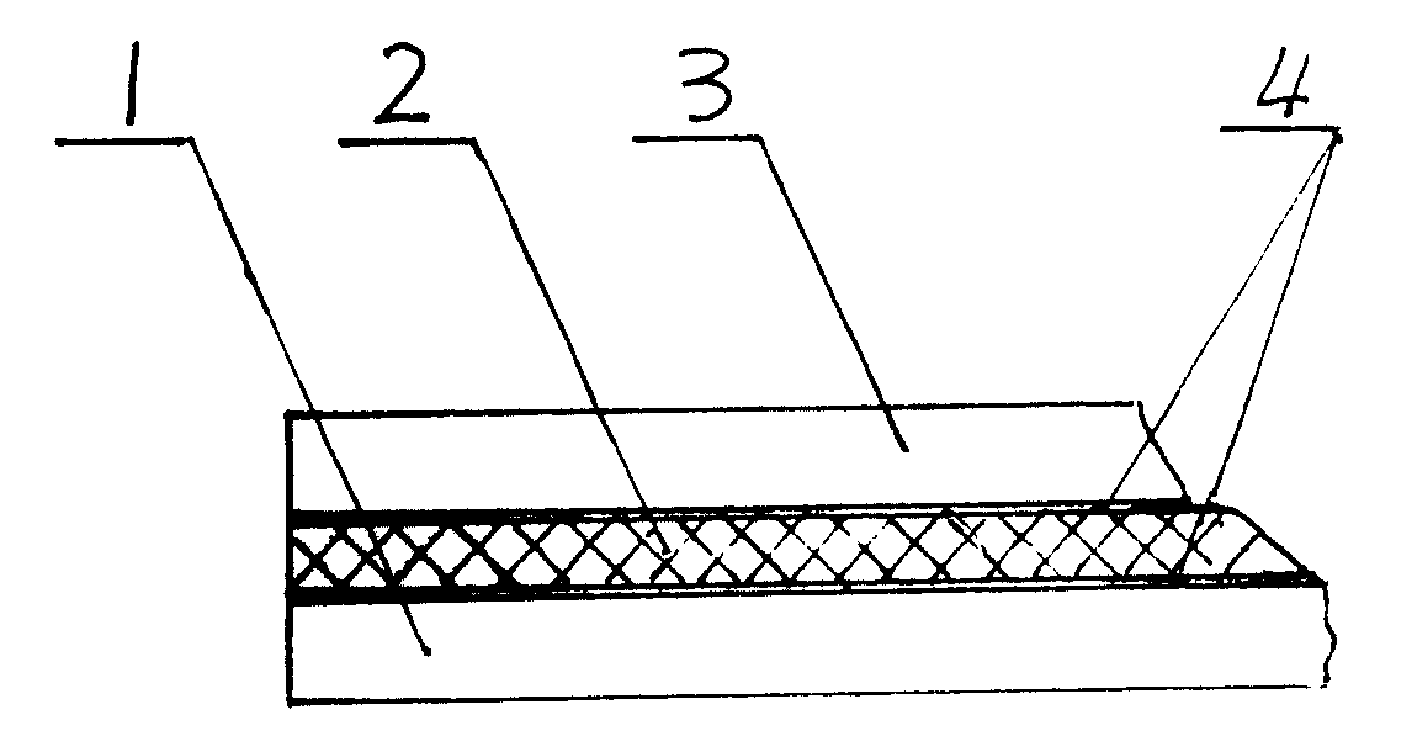

[0015] The bottom plate 1 and the surface plate 3 are wooden plywood, both of which have a thickness of 6 mm; the thickness of the damping sandwich plate is 3 mm, and its formula is: recycled rubber powder 45%, asphalt 6%, waste plastic powder 5%, sulfur 3%, mica powder 10 %, zinc oxide 3%, wollastonite powder 26%, dioctyl phthalate 2%; the particle size of the regenerated rubber is 40 mesh, and the particle size of the powder in the filler is 60 mesh; the method is to mix the recycled rubber powder Desulfurization treatment, put it into the mixer, then put in the filling material, fully stir evenly, and then put this mixture on the open rubber mixer to extrude into a damping sandwich plate sheet with a thickness of 3mm; the two outer surfaces of the damping sandwich plate are uniform Impregnate the adhesive, place it between the bottom plate and the surface plate, lay it flat on the worktable of the hot press, press 10Mpa, heat up to 120°C, keep it for 15 minutes under the pre...

Embodiment 2

[0017] The bottom plate 1 and the surface plate 3 are bamboo plywood with a thickness of 7mm; the thickness of the damping sandwich plate is 2mm, and its formula is 40% of recycled rubber, 6% of asphalt, 3% of sulfur, 8% of waste plastic powder, and 15% of mica powder , calcite powder 18%, dioctyl phthalate 5%, zinc oxide 5%; The particle size of the powder in the filler is 80 orders; The manufacturing method step is the same as embodiment 1, and the molding condition of its composite damping plate is Apply a pressure of 10Mpa, heat up to 140°C, and press for 20 minutes.

Embodiment 3

[0019] Bottom board 1 bamboo plywood, thickness 3mm; surface board 3 wooden plywood 6mm; damping interlayer board thickness 6mm, its formula is recycled rubber powder 35%, mica powder 20%, waste plastic powder 5%, asphalt 5%, calcite powder 15%, ball clay powder 14%, sulfur 2%, zinc oxide 2%, dioctyl phthalate 2%; the particle size of the recycled rubber powder is 80 mesh, and the particle size of the powder in the filler is 40 mesh; manufacturing The steps of the method are the same as those in Example 1, and the molding conditions of the composite damping plate are as follows: applying a pressure of 16 MPa, heating to 140° C., and pressing for 6 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com