Bi component paint used as top coating, producing process and usage thereof

A production method and two-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of not fully satisfying the development of high-tech industries, and achieve bright colors, good electrical insulation, and good pollution resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

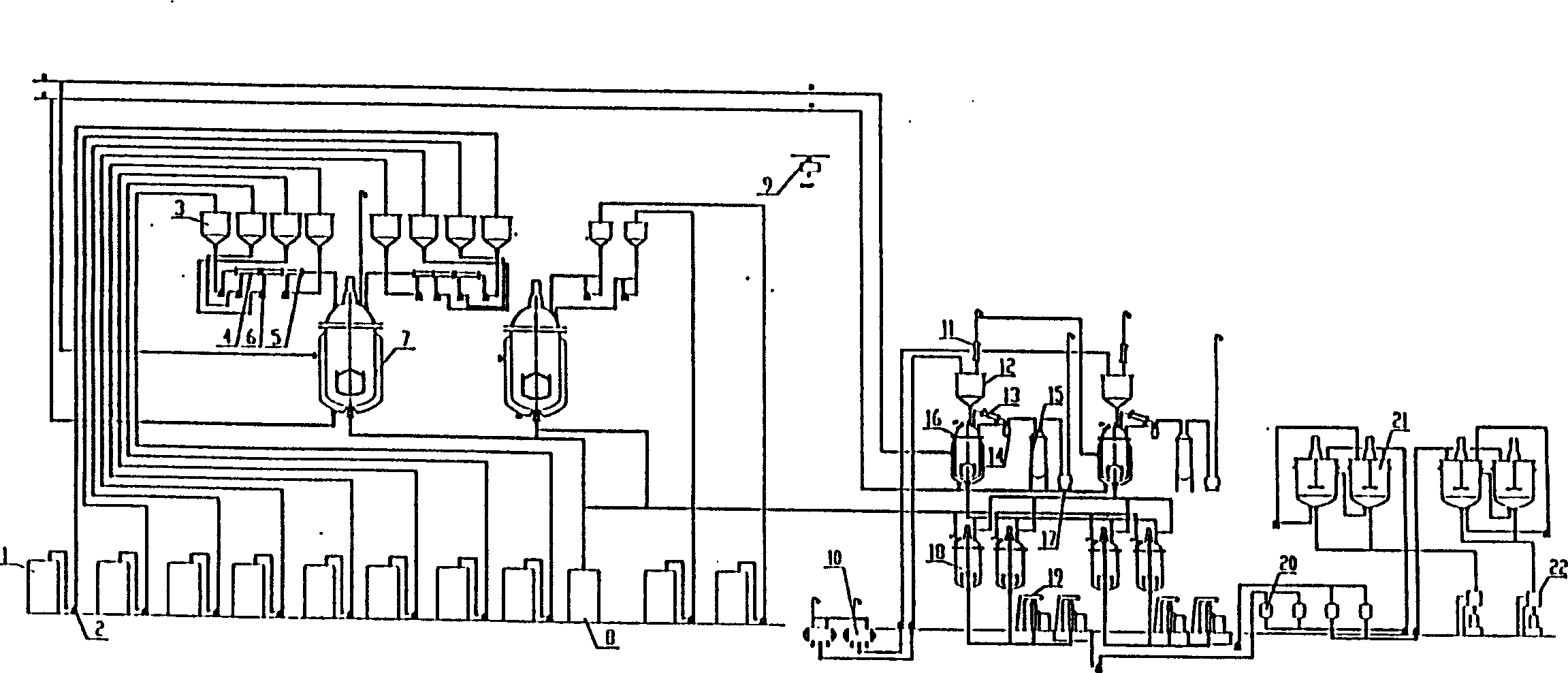

Method used

Image

Examples

Embodiment 1

[0040] The composition of the epoxy resin solution of the A component is: 5 parts of butanol, 8 parts of cyclohexanone, 12 parts of xylene, 10 parts of epoxy resin and 2 parts of linear epoxy resin. Wherein the epoxy resin is epoxy resin 601, and the linear epoxy resin is epoxy resin 621, produced by Wuxi Resin Factory.

[0041] Component A is: 5 parts of polyurethane resin, 2 parts of elemental silicone resin, 2 parts of amino resin, 2 parts of polyester resin, 1 part of hexyl diisocyanate and 15 parts of titanium dioxide, 8 parts of talcum powder, 6 parts of precipitated barium sulfate, 2 parts of bentonite and 10 parts of epoxy resin solution. Among them, the polyurethane resin is polyurethane resin 7110 A, the elemental silicone resin is produced by Shanghai Resin Factory, the amino resin is amino resin 590-4, produced by Tianjin Resin Factory, and the polyester resin is polyester resin 3201, produced by Shanghai Xinhua Resin Factory. Hexyl diisocyanate was produced by Ba...

Embodiment 2

[0049] The difference from Example 1 is that the raw material ratio of the epoxy resin solution of A component is: 8 parts of butanol, 12 parts of cyclohexanone, 16 parts of xylene, 12 parts of epoxy resin 604, linear epoxy resin 4 parts share. The stirring speed is 1000 rpm, the temperature is gradually raised to 140 °C at a rate of 2 °C / min, and the gas supply is stopped at 120 min.

[0050] The raw material ratio of the finished product of component A is: 10 parts of polyurethane resin, 4 parts of elemental silicone resin, 2.5 parts of amino resin, 2.5 parts of polyester resin, 2 parts of hexyl diisocyanate, 15 parts of 808 red powder, and 12 parts of lithopone , 8 parts of precipitated barium sulfate, and 18 parts of epoxy resin solution. The stirring speed is 1300 rev / min, the stirring time is 40min, and the fineness is 35 microns.

[0051] The raw material ratio of the finished product of component B is: 94 parts of polyurethane 7110, 1 part of butanol, 1 part of cyclo...

Embodiment 3

[0055] The difference from Example 1 is that the raw material ratio of component A epoxy resin liquid is: 10 parts of butanol, 15 parts of cyclohexanone, 18 parts of xylene, 20 parts of epoxy resin, and 8 parts of linear epoxy resin . The stirring speed is 1150 rev / min, the temperature is gradually raised to 160°C at a speed of 4°C / min, and the gas supply is stopped at 90 minutes.

[0056] The raw material ratio of the finished product of component A is: 15 parts of polyurethane resin, 6 parts of elemental silicone resin, 5 parts of amino resin, 5 parts of polyester resin, 5 parts of hexyl diisocyanate and 10 parts of cobalt green, 12 parts of lithopone, 8 parts of precipitated barium sulfate, 2 parts of bentonite and 25 parts of epoxy resin solution. The stirring speed is 1350 rpm, the stirring time is 30 minutes, and the fineness is 20 microns.

[0057] The raw material ratio of the finished product of component B is: 90 parts of polyurethane 7110A, 1 part of butanol, 1 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com