Improved method of purifying gas containing urea dust

A urea and dust technology, which is applied in the field of improved purification of urea-containing dust gas, to achieve the effects of avoiding explosion problems, small emissions, and reducing ammonia emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

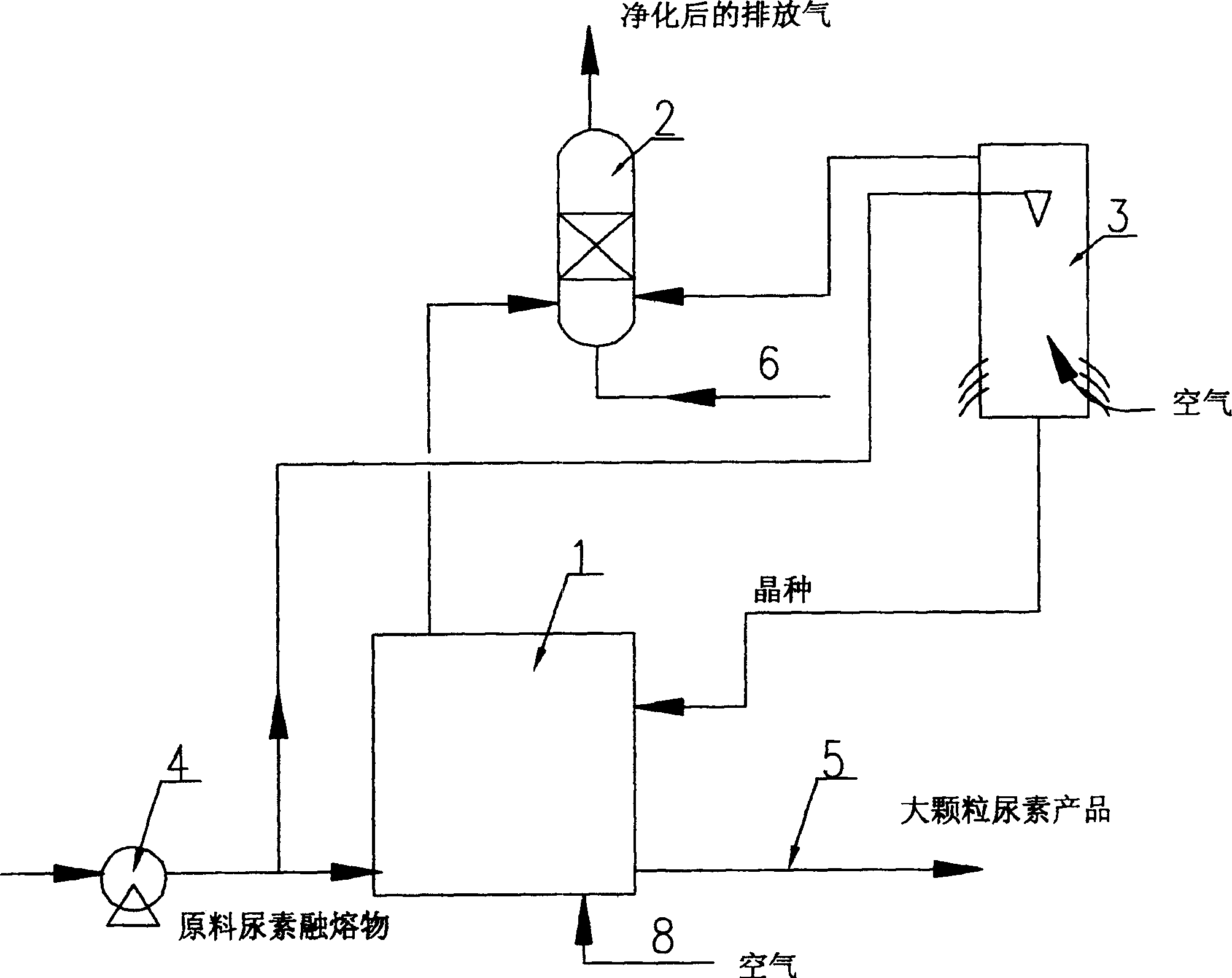

Embodiment 1

[0031] figure 1 The middle is the flow chart of the principle of using the scrubber to purify all the tail gas. 97-85% of the raw material urea melt is sent to the large-grain urea unit 1 through the urea melt pump 4 at a temperature of about 134-138°C, and 3-15% is sent to the urea prilling tower 3 . The small granular urea with a temperature of about 45-60°C at the bottom of the prilling tower 3 is sent to the large granular urea plant 1 as a crystal seed, and after contacting with the urea melt sent by the urea melting pump 4, the large granular urea product is produced. The washing tower 2 receives the tail gas containing urea dust from the prilling tower 3 and the large-grain urea plant 1, and discharges it to the atmosphere after being washed. The tail gas 6 containing hydrogen and ammonia from the urea plant can also be sent to the washing tower for washing and then discharged. Since the large-grain urea plant adopted in the present invention is a double-drum fluidiz...

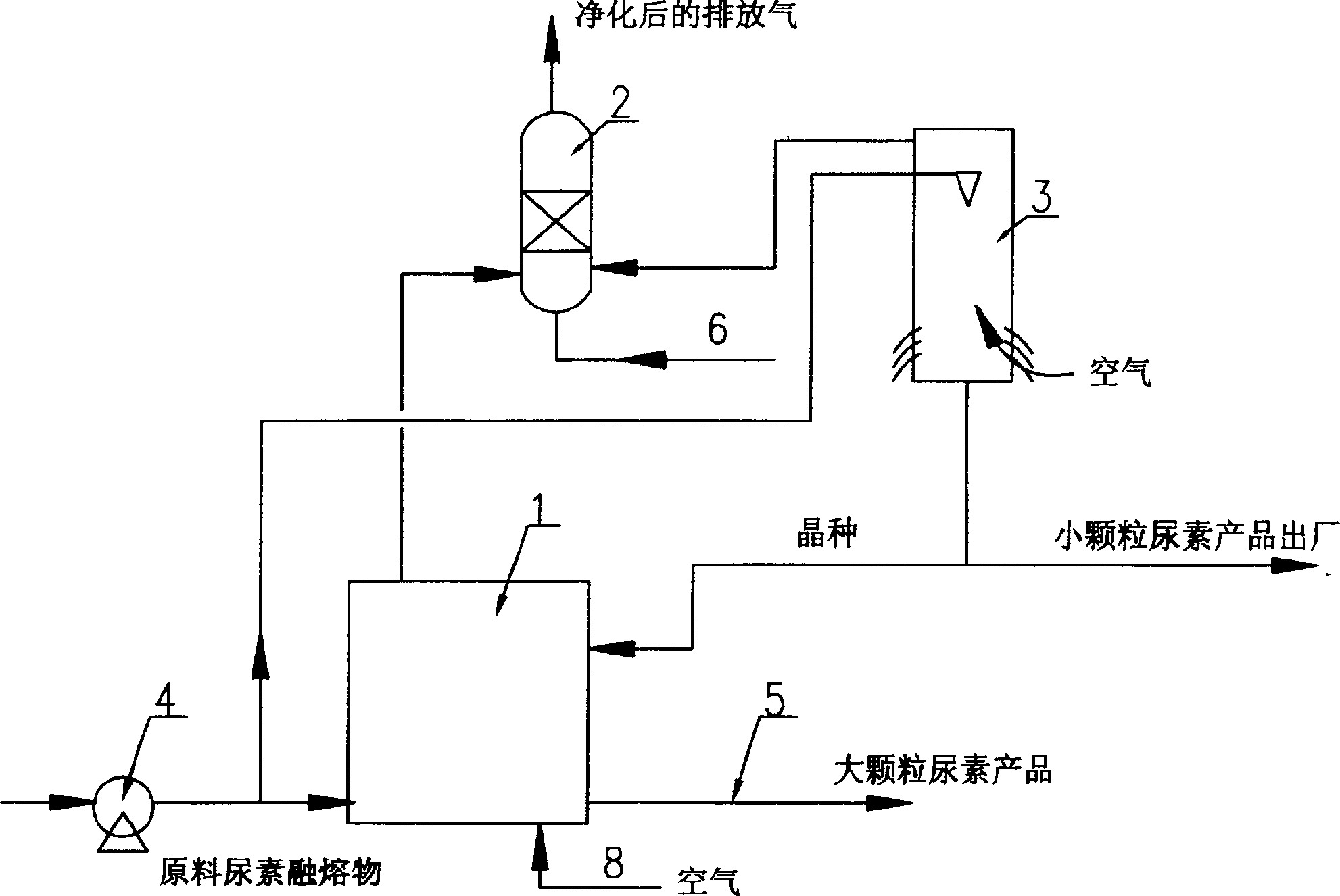

Embodiment 2

[0033] figure 2 It adopts scrubber to purify all the tail gas, and the product contains both large and small particle urea. The difference from Example 1 is that the quantity of urea melt that enters the prilling tower from the raw material urea melt pump 4 is relatively large, and the quantity of small granular urea produced is greater than the number of seed crystals required by the large granular urea plant. Small granular urea leaves the factory as a product.

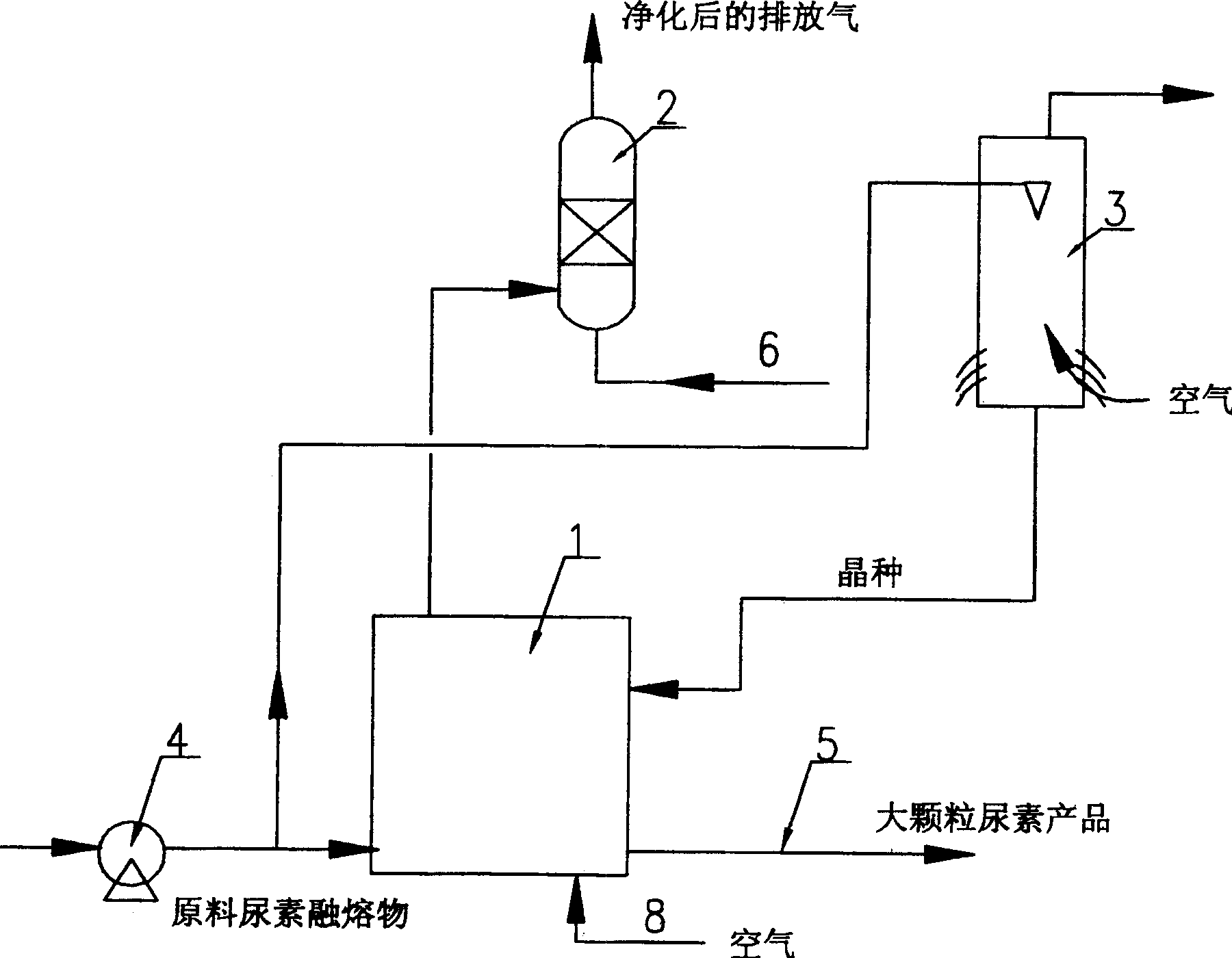

Embodiment 3

[0035] image 3 It is a process in which a scrubber is used to purify part of the tail gas, and all products are large-grained urea. The difference from Example 1 is that the gas in the prilling tower 3 is directly emptied and no longer enters the washing tower 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com