Electronic emission device, electron source and image forming apparatus using the same device and its producing method

A technology of electron emission and electron source, applied in the field of electron source, can solve the problems of unsatisfactory electron emission characteristics and efficiency

Inactive Publication Date: 2005-10-12

CANON KK

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] However, the above-mentioned electron-emitting device proposed by M. Hartwell is not satisfactory in terms of stable electron-emitting characteristics and efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

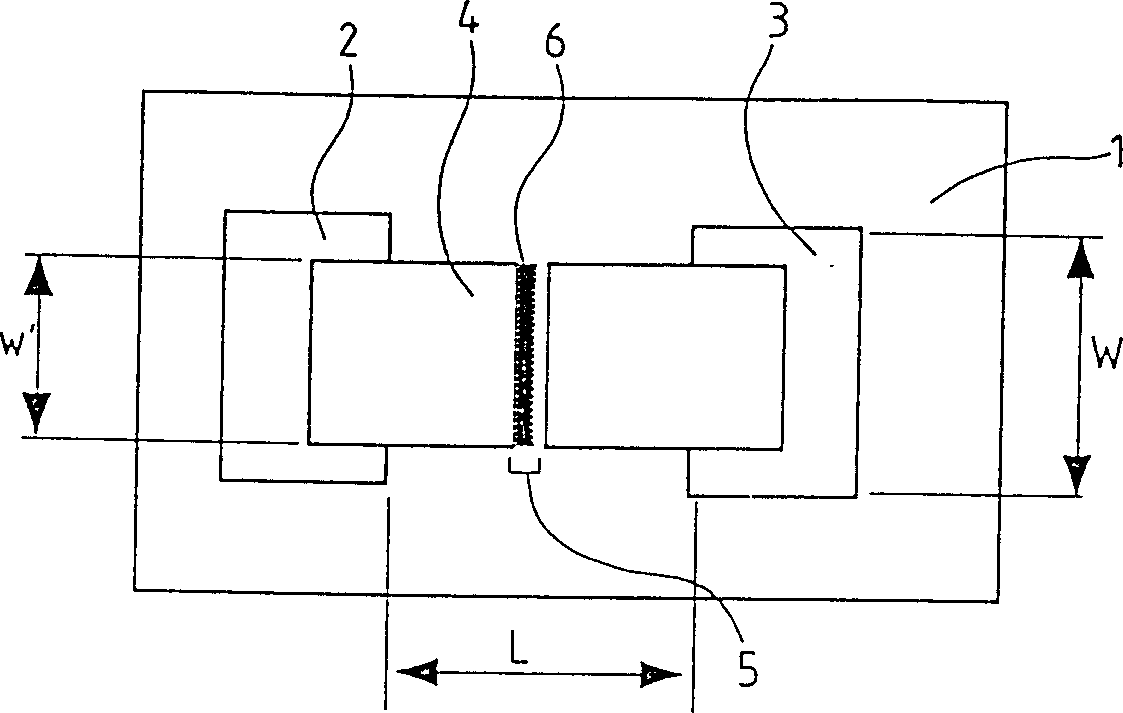

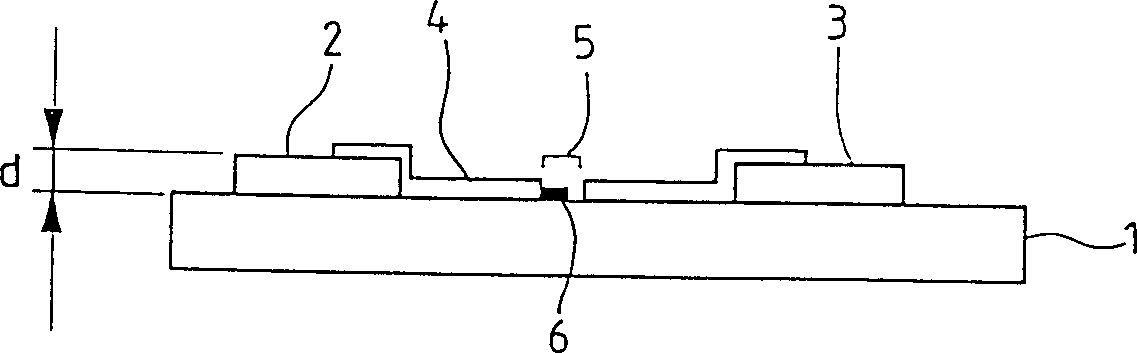

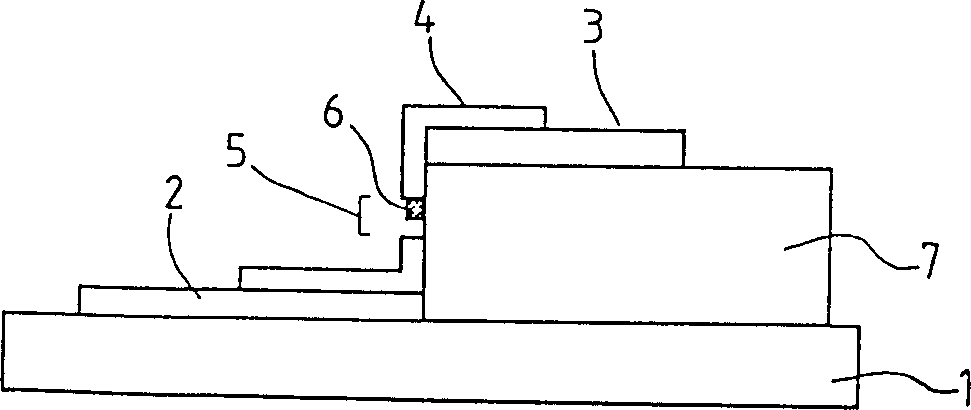

In an electron-emitting device including, between electrodes, an electroconductive film having an electron emitting region, the electroconductive film has a film formed in the electron emitting region and made primarily of a material having the higher melting point than that of a material of the electroconductive film. Alternatively, the electroconductive film has a film formed in the electron emitting region and made primarily of a material having a higher temperature, at which the material develops a vapor pressure of 1.3 x 10<-><3> Pa, than that of a material of the electroconductive film. A manufacture method of an electron-emitting device includes a step of forming a film made primarily of a metal in the electron emitting region of the electroconductive film. An image-forming apparatus comprising the electron-emitting devices has high luminance and excellent stability in operation.

Description

technical field [0001] The present invention relates to an electron-emitting device, and more particularly to an electron-emitting device that maintains stability over a long period of time, an electron source using the electron-emitting device, an image forming apparatus such as a display device using the electron source, and an exposure device. device, and a method of manufacturing an electron-emitting device, an electron source, and an image forming device. Background technique [0002] There have been two main types of electron-emitting devices in the past, namely, a hot cathode type electron-emitting device and a cold cathode type electron-emitting device. The cold cathode type electron emission devices include field emission type (hereinafter abbreviated as FE), metal / insulator / metal layer type (hereinafter abbreviated as MIM) and surface conduction type. [0003] Examples of FE electron-emitting devices are in W.P. Dyke and W.W. Dolan, "Field emission" ("Field emissi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01J9/02H01J1/316H01J29/04H01J29/46H01J31/12

CPCH01J2329/00H01J1/316H01J9/027H01J31/12

Inventor 岩崎达哉山野边正人塚本健夫山本敬介浜元康弘

Owner CANON KK

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com