Production method of millimeter-level microlens array

A technology of microlens array and manufacturing method, which is applied in the directions of lenses, optics, instruments, etc., can solve the problems of components that cannot be processed with arbitrary surface shapes and two-dimensional array structures, difficult to eliminate internal stress, complicated process flow, etc. Reproduce simulation and mold release, controllable vulcanization process, good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 is to manufacture a continuous embossed microlens array with a sub-aperture of φ2 mm, a numerical aperture of 0.2, an array number of 8×8, and a lens sagittal height of 0.2 mm.

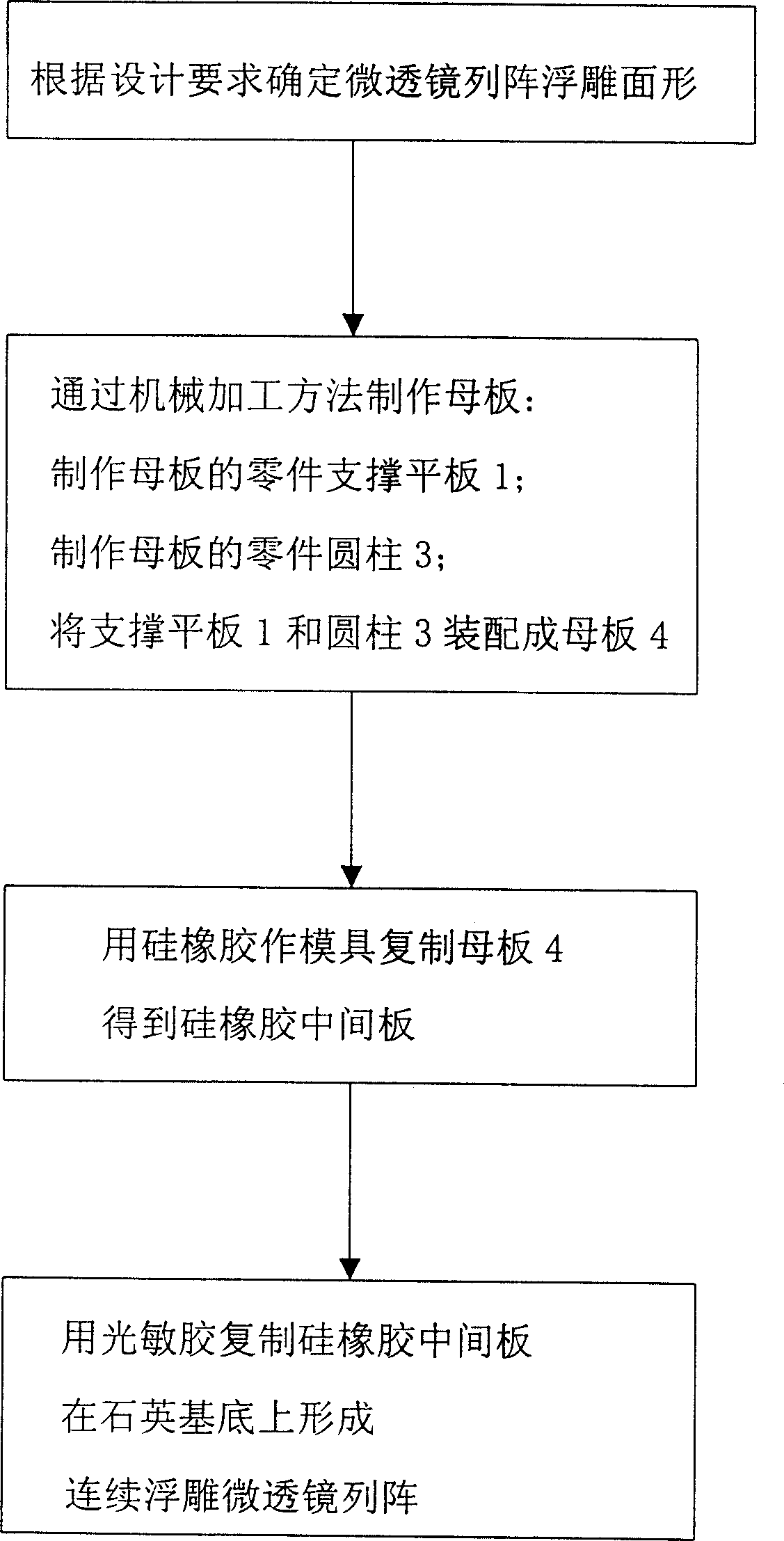

[0040] The technological process of embodiment one preparation method is as figure 1 Shown:

[0041] 1, determine microlens embossed surface shape: according to the parameter of embodiment one, the lens that determines the made microlens array is a convex lens, and its curved surface shape is a paraboloid;

[0042] 2. Make the motherboard by machining 4:

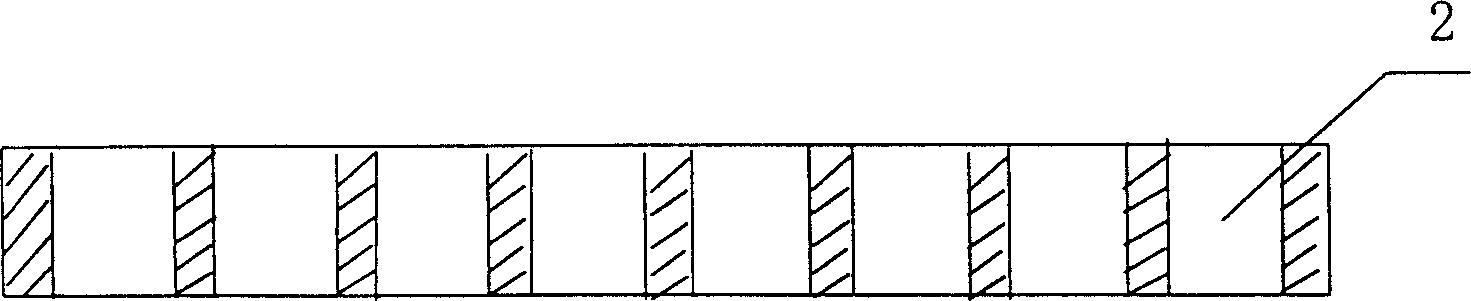

[0043] ①. A supporting plate 1 is made of No. 45 steel. Such as image 3 As shown, a through hole 2 is drilled on the support plate 1, and the diameter of the through hole 2 is equal to the microlens sub-aperture φ2mm. Such as figure 2 As shown, there are 8×8 through holes 2 on the support plate 1, and the distance between the through holes 2 is the center distance of the microlens array;

[0044] ②. Make 8×8 cylinders 3 ....

Embodiment 2

[0048] The second embodiment is to make a continuous embossed microlens array with a sub-aperture diameter of φ3m, an array number of 16×16, and a lens sagittal height of 0.5mm.

[0049] The technological process of embodiment two is as Figure 9 Shown:

[0050] 1. Determine the surface shape of the microlens relief:

[0051] According to embodiment two production parameters, it is determined that the replicated lens is a concave lens, and the curved surface shape is a hyperboloid;

[0052]2. Make the motherboard by mechanical processing:

[0053] According to the determined microlens relief surface shape, the stainless steel is processed by a CNC precision milling machine to make a master plate;

[0054] 3. Copy the master plate with photosensitive adhesive to obtain the microlens relief surface shape required in Embodiment 2, and complete the production of the microlens array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com