Method of welding steel guide rails

A guide rail and arc welding technology, which is applied to the joints of rails, rails, welding equipment, etc., can solve the problems of complex equipment, high cost, and inability to provide this time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

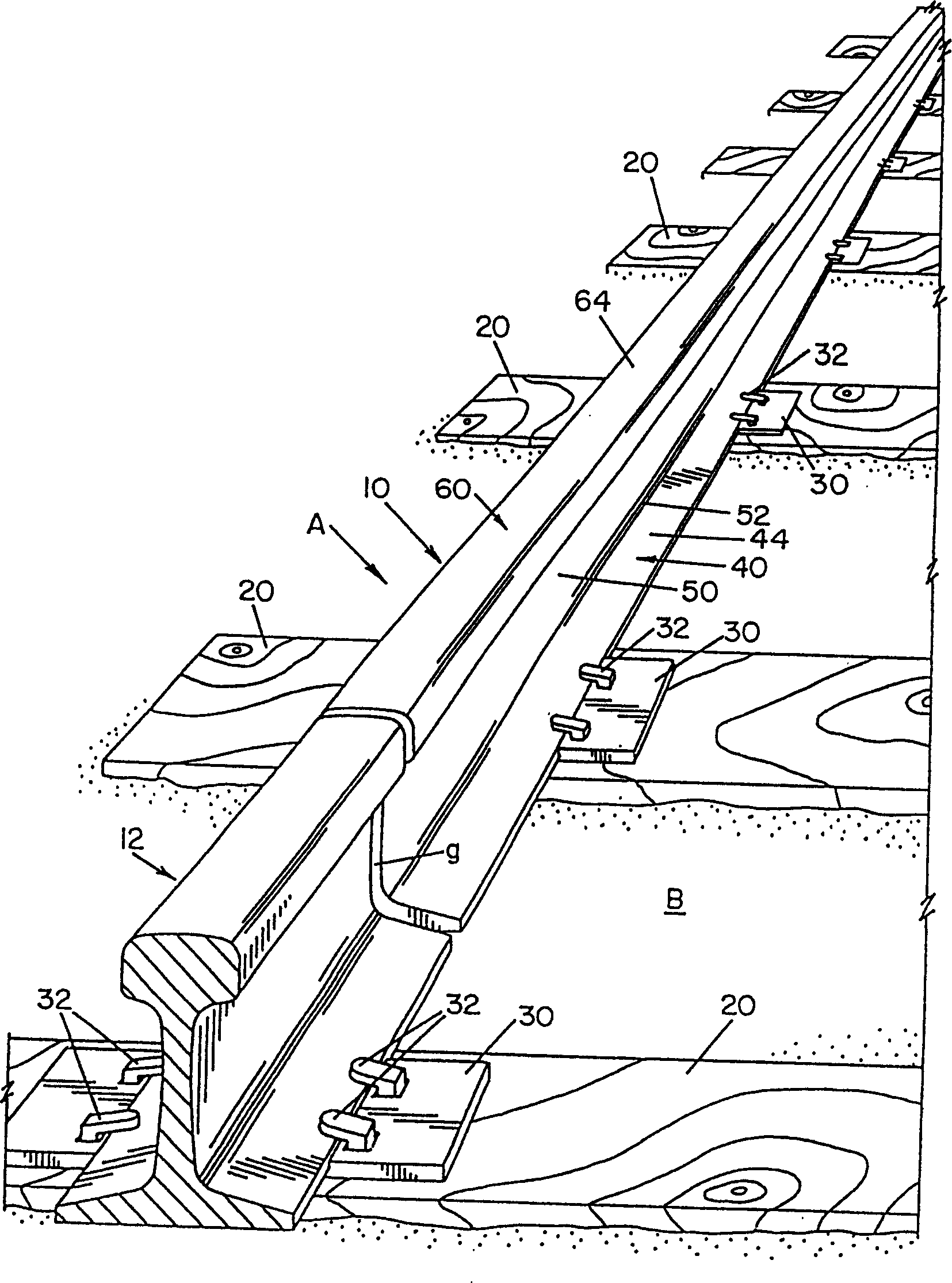

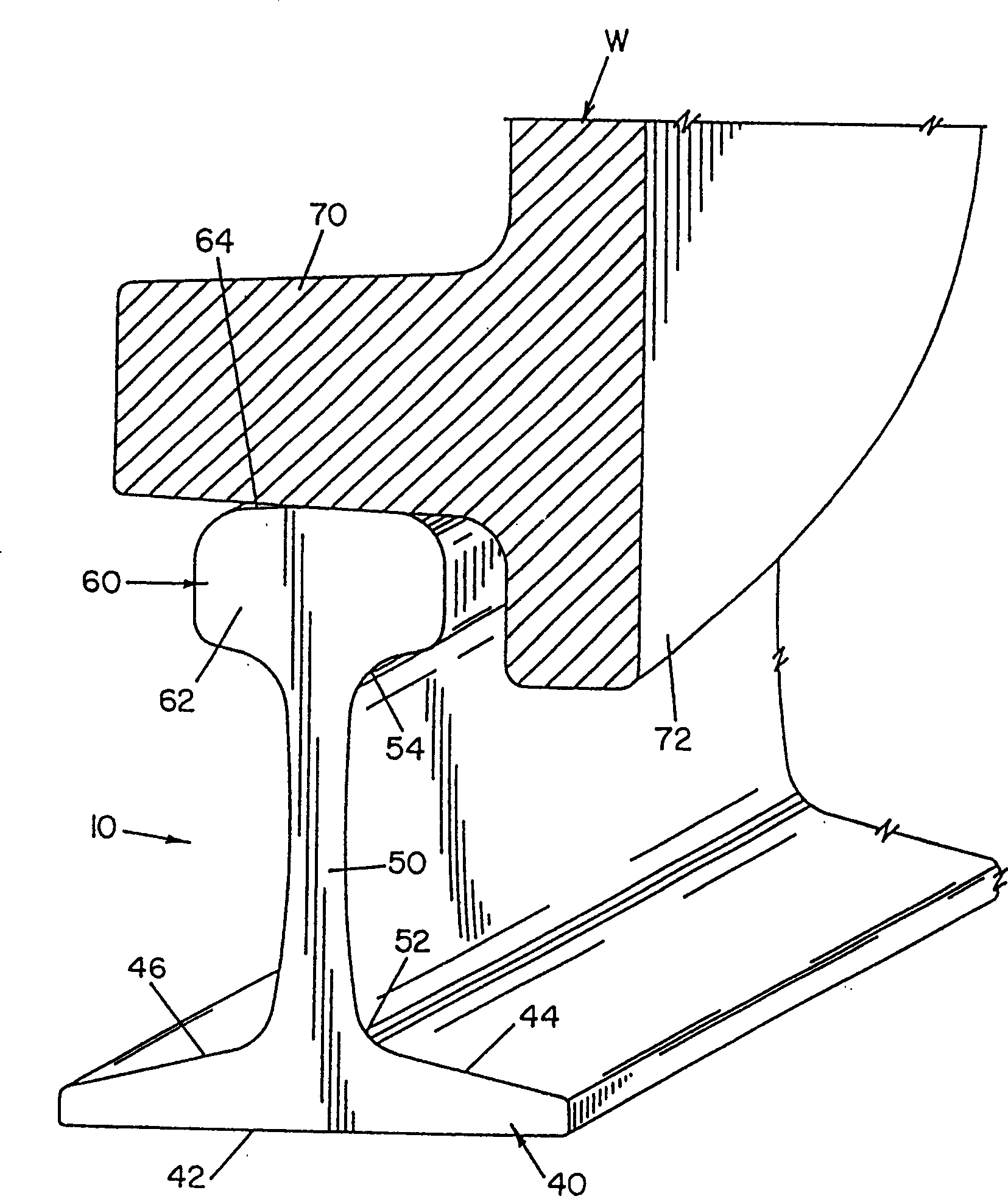

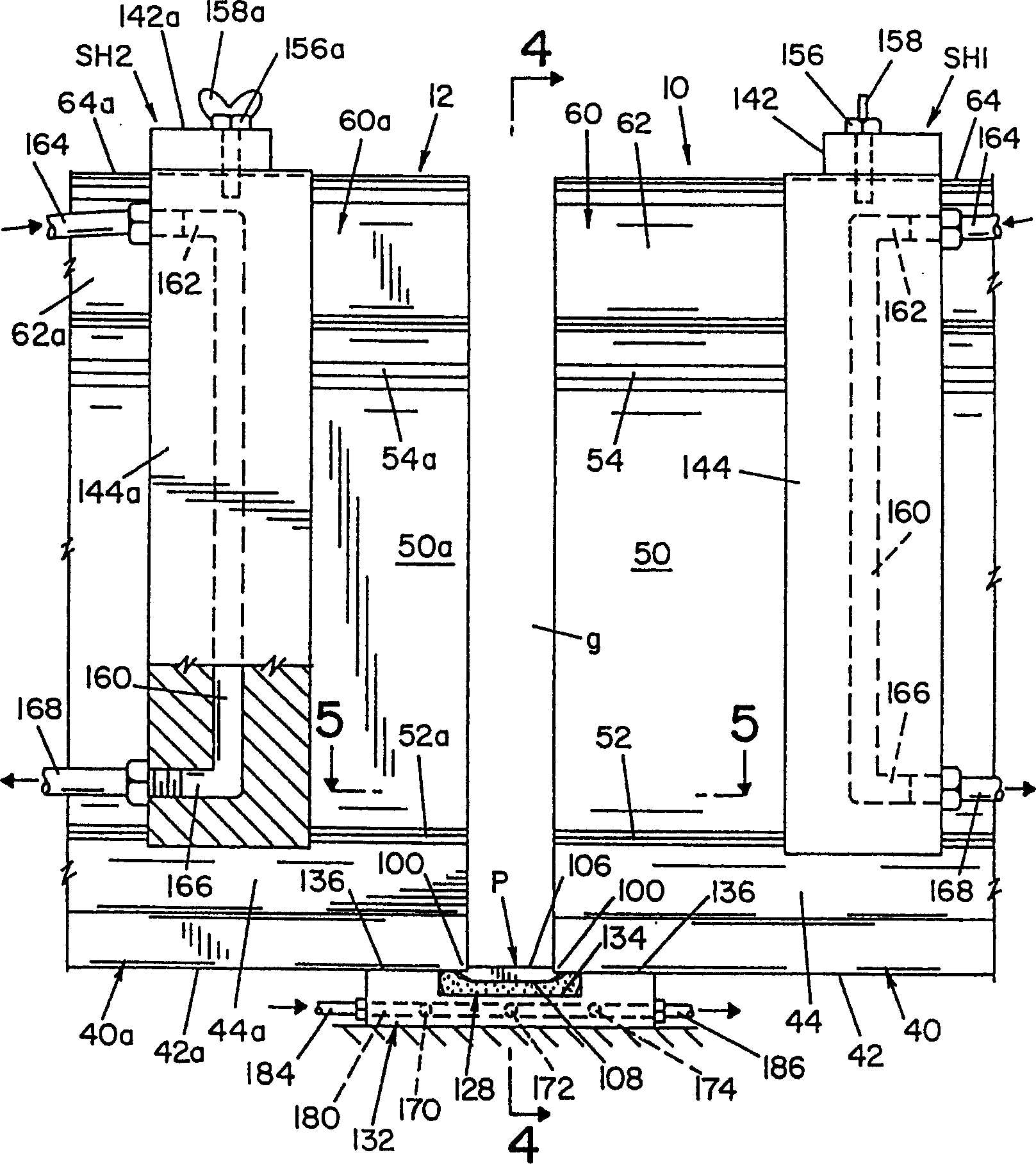

[0047] Referring now to the accompanying drawings, the purpose of which is to illustrate and not limit the preferred embodiment of the present invention, figure 1 A steel rail A lying on a rail bed B is shown, comprising rails 10 and 12 to be joined to form a continuous welded track. The guide rails 10 and 12 are supported on the rail bed B by sleepers 20, steel support covers 30 and channel nails 32, the rails being spaced longitudinally to form a gap g therebetween which is to be filled with molten weld metal so that the two rails are joined together in this The location is connected. The gap 9 may be the gap between two rail sections to be repaired, or the gap between two rail sections initially to be installed as a continuous welded rail system. If the gap g is for maintenance, it is often necessary to cut the rail and insert a long section of the rail. This method is used to repair broken rails, broken seams or damaged seams. In all examples, the two spacer rails 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com