LED in III group nitride and its manufacturing method

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting the light-emitting characteristics of components, reducing the effective carrier concentration of p-type nitrides, and low doping concentration, so as to improve current dispersion ability, reduction of hydrogen passivation, production and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

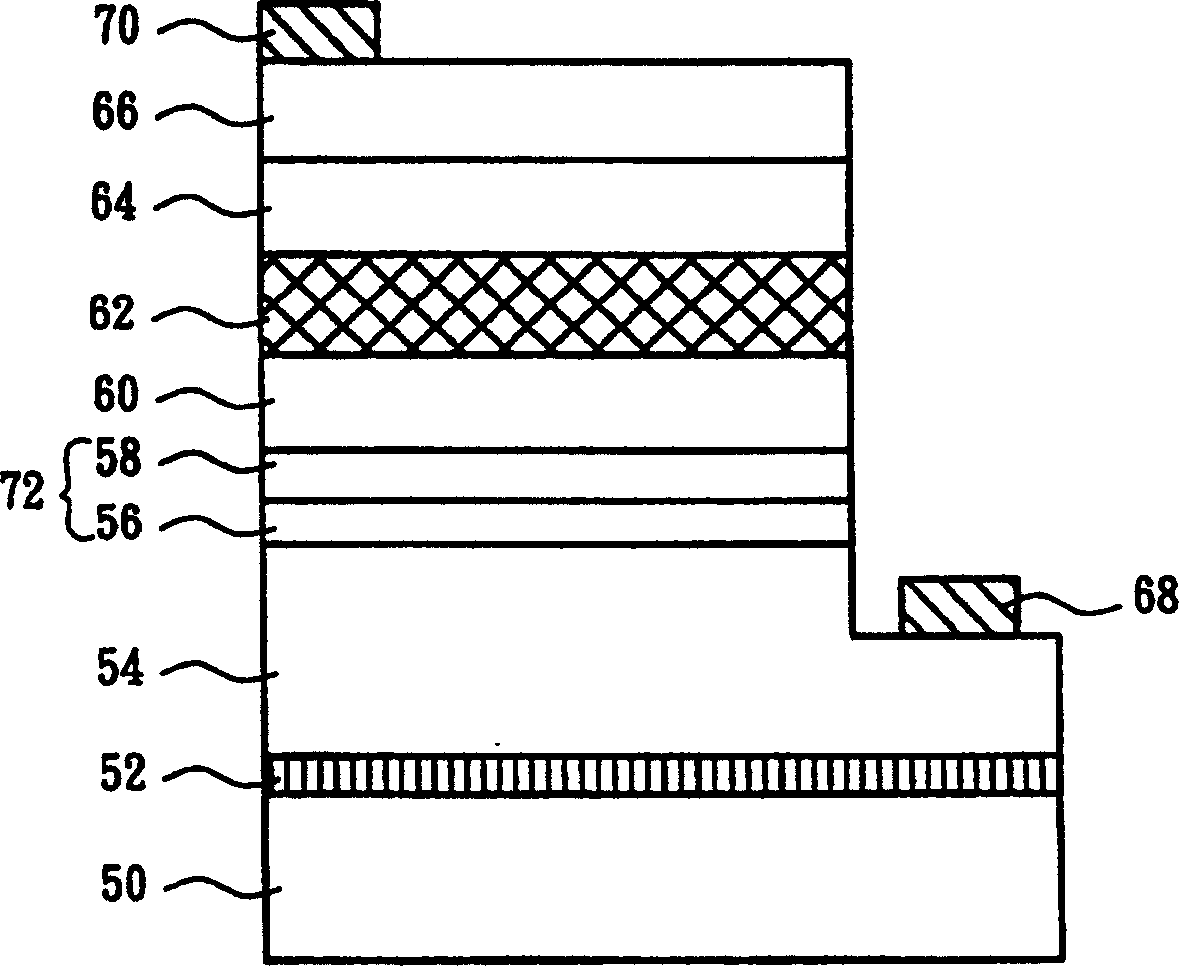

[0015] figure 2 It is a cross-sectional view of the structure of a III-nitride light-emitting diode according to the present invention. Please refer to figure 2 , the present invention uses a method for manufacturing a III-nitride light-emitting diode to simultaneously illustrate the structure of a III-nitride light-emitting diode. First, an epitaxial structure is formed on the substrate 50, and the epitaxial structure may sequentially include: a low-temperature buffer layer 52 (also known as a nucleation layer), an n-type ohmic contact layer 54, a degenerate junction (DegenerateJunction) 72, a wide energy gap p-type confinement layer 60 , active layer 62 , n-type confinement layer 64 with wide energy gap, and n-type ohmic contact layer 66 . Next, the n-type conductive electrode 68 and the conductive electrode 70 are vapor-deposited to complete the fabrication of the III-nitride light-emitting diode of the present invention. Among them, the III-nitride light-emitting diod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com