Process for forming transistor with metallic silicide on source and drain

A technology of metal silicide and metal silicide layer, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of low energy use efficiency, low efficiency, and difficult to form accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment of the present invention is a method of forming a metal-oxide-semiconductor transistor with metal silicide on the source and drain, comprising at least the following steps:

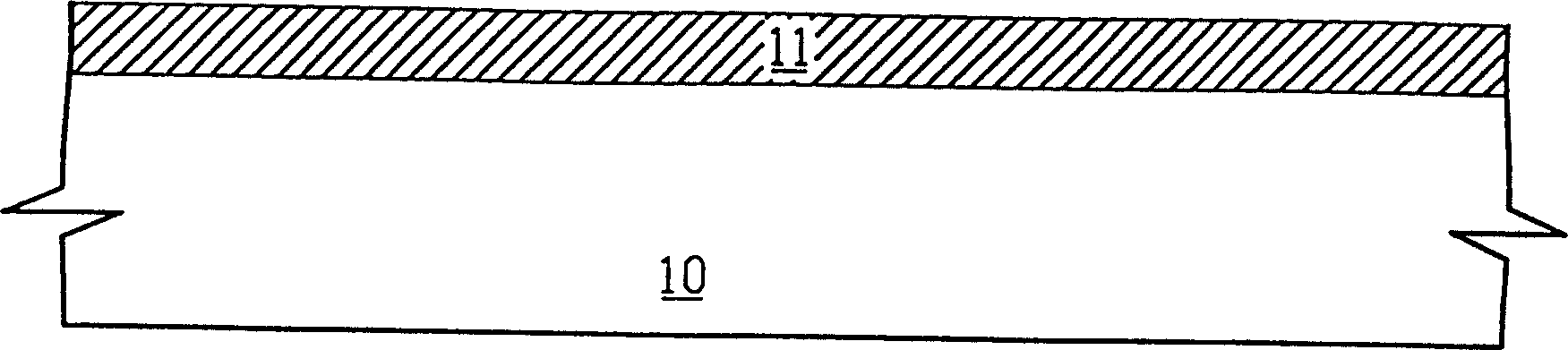

[0023] like Figure 1A As shown, a silicon substrate 10 is provided and a first dielectric layer 11 is formed on the silicon substrate 10. Here, the first dielectric layer 11 can at least serve as a gate dielectric layer. The first dielectric layer 11 is typically an oxide layer, and typically has a thickness of about 50 to 300 angstroms.

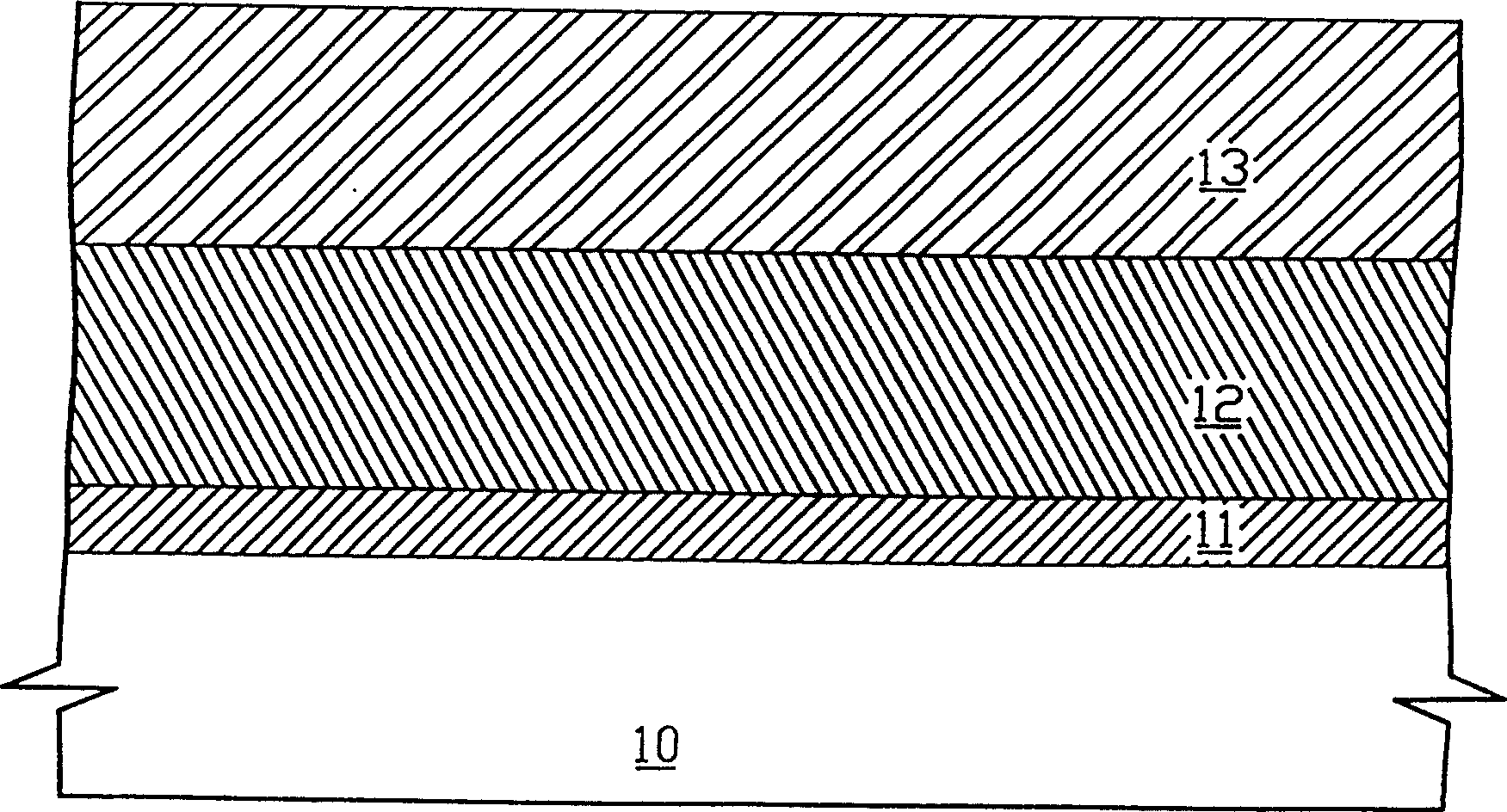

[0024] like Figure 1B As shown, a conductor layer 12 is formed on the first dielectric layer 11 and a second dielectric layer 13 is formed on the conductor layer 12 . The conductor layer 12 can be used at least as a gate conductor layer. The conductor layer 12 can be one of the following: a metal layer, a polysilicon layer and a polysilicon metal layer, and its typical thickness is about 500 angstroms to 3500 angstroms. The second diel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com