Negative pressure adiabatic flash tank and adiabatic flash method for tar styrene recovery

An adiabatic flash evaporation and negative pressure technology, which can be used in flash evaporation, distillation purification/separation, organic chemistry, etc., and can solve problems such as pressure drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

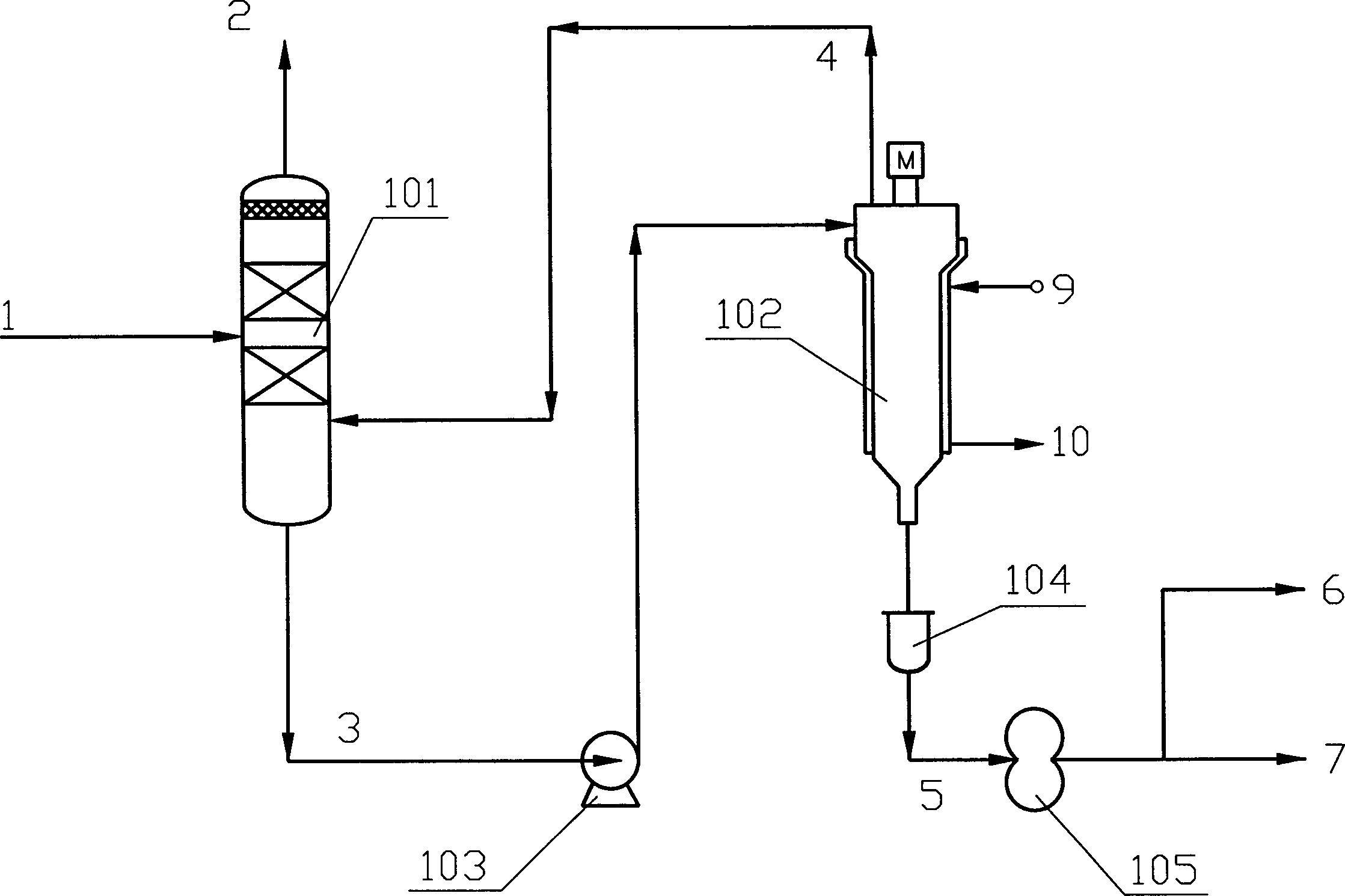

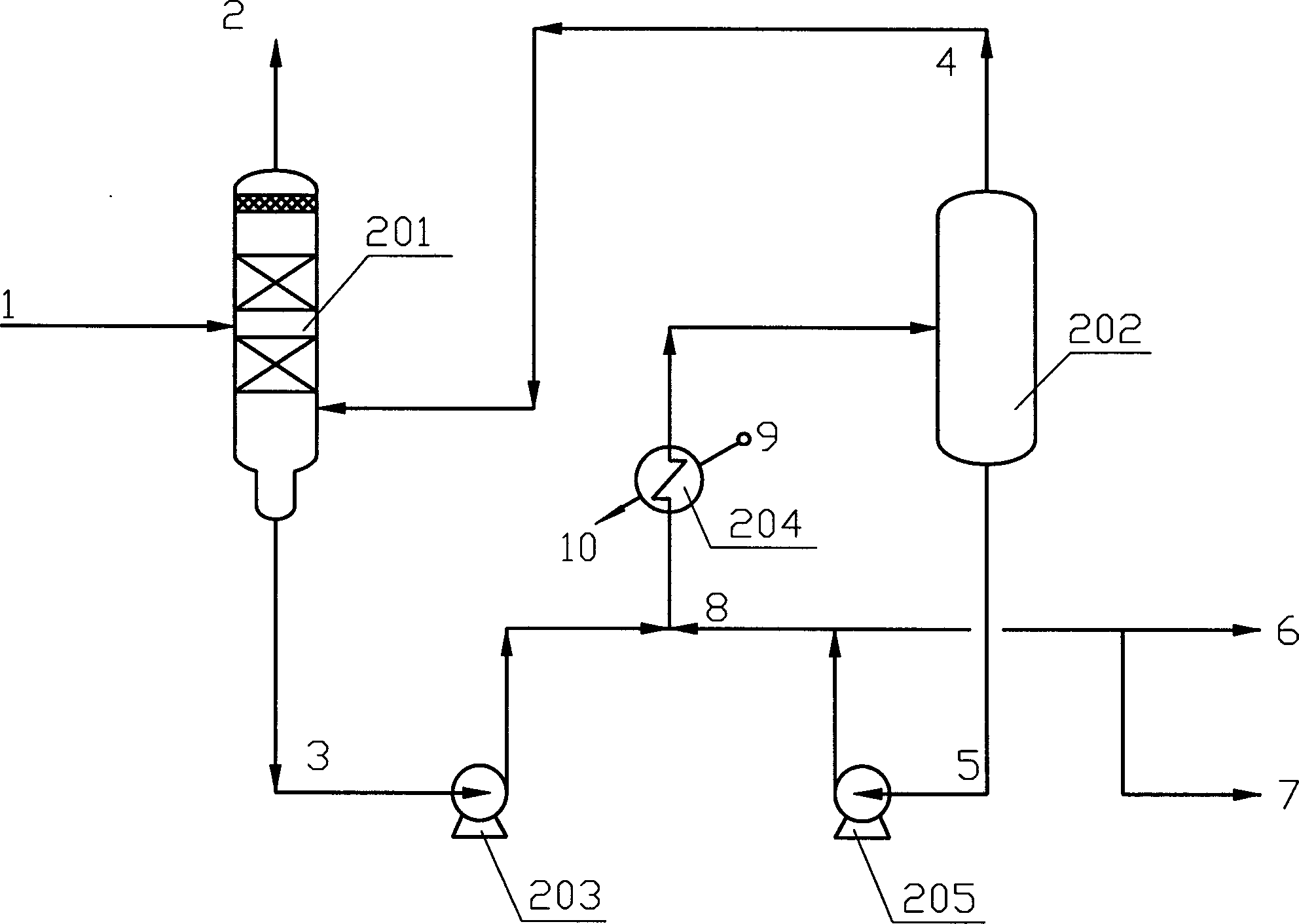

Embodiment 1

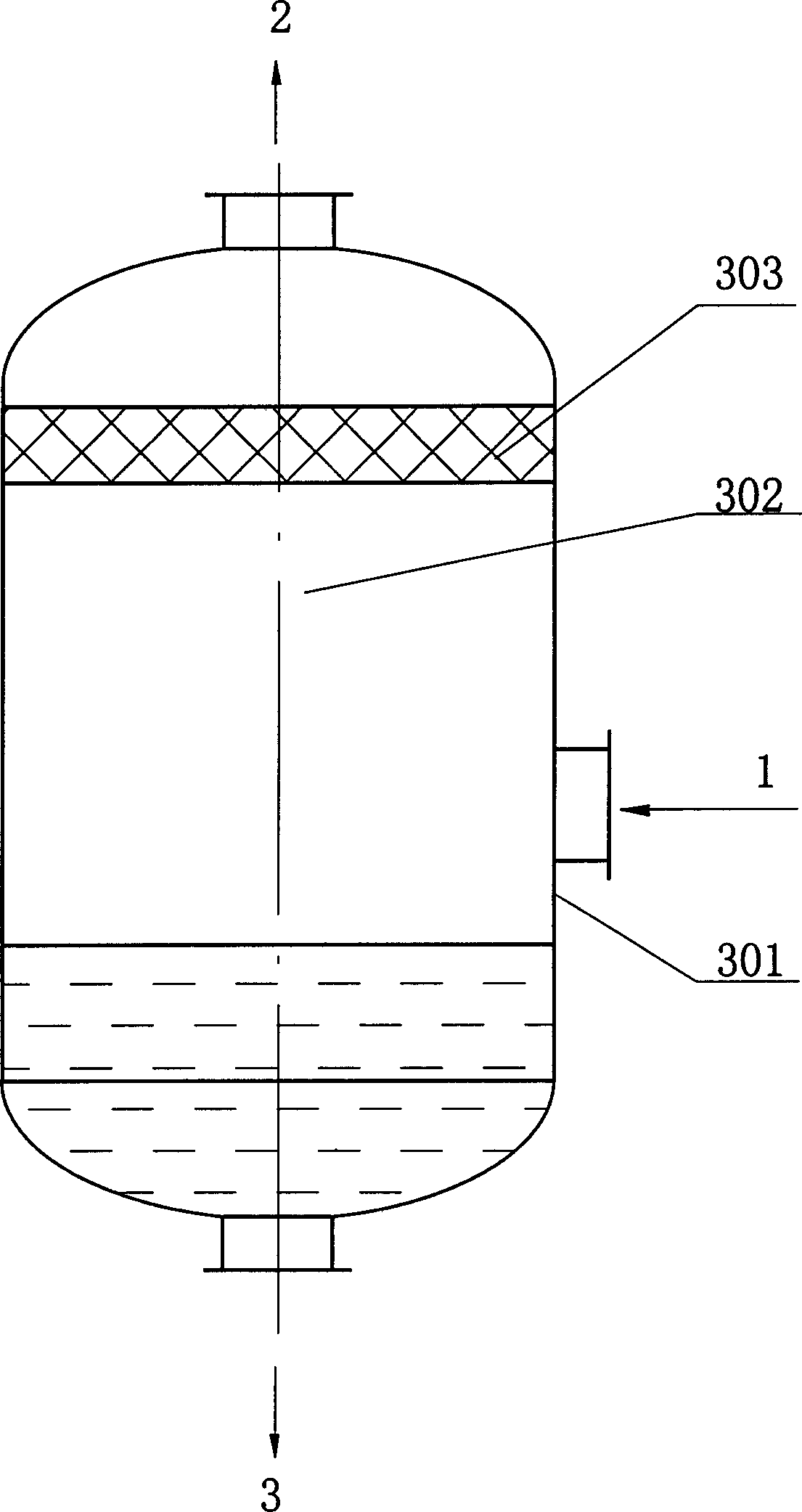

[0057] A certain 100,000 tons / year styrene plant, its tar styrene recovery adopts the side wall horizontal feed adiabatic flash tank with flat oblong fan nozzle of the present invention.

[0058] Figure 8 are the front and top views of the adiabatic flash tank. In the figure, the inner diameter of the flash tank Di = 1.1 meters; the height of the tangent line H = 2.8 meters; the height of the tangent line from the center line of the feed inlet to the upper head h = 1.8 meters; the nominal diameter of the feed pipe d 1 It is DN300; the nominal diameter of the gas outlet pipe on the top of the tank is d 2 It is DN300; the nominal diameter of the tar outlet pipe at the bottom of the tank is d 3 It is DN125; the central angle α=60° of the fan-shaped nozzle; the length 1=0.5Di=0.55 meters of the oblong nozzle; the width b=0.14 meter of the oblong nozzle.

[0059] The operating pressure of the adiabatic flash tank is 20KPaA; the operating temperature is 146°C. The styrene conce...

Embodiment 2

[0062] According to the conditions of Example 1, only the type of the horizontal feed nozzle on the side wall of the adiabatic flash tank was changed. Do not adopt the fan nozzle with flat oblong mouth of the present invention, but will Figure 8 The feed pipe with a nominal diameter of DN300 is directly inserted into the side wall of the flash tank (such as Figure 5 and Figure 6 shown), used as the feed nozzle.

[0063] The result of the adiabatic flash operation is: the concentration of styrene in the discharged tar is 8% (weight); the discharge of tar is 3.5 tons per day; the amount of styrene lost with the discharge of tar is 0.88 kg / ton of styrene product, which is higher than the design value 0.79 kg / ton of styrene products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com