Static frequency-measuring method and device for classifying piezoelectric ceramic chiops and devices

A sorting device, a technology for ceramic sheets, applied in measurement devices, piezoelectric/electrostrictive/magnetostrictive devices, and single semiconductor device testing, etc., can solve sorting speed limitations, low efficiency, inconvenient maintenance, etc. problems, to avoid wear and tear, improve sorting accuracy, and have a friendly human-machine interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

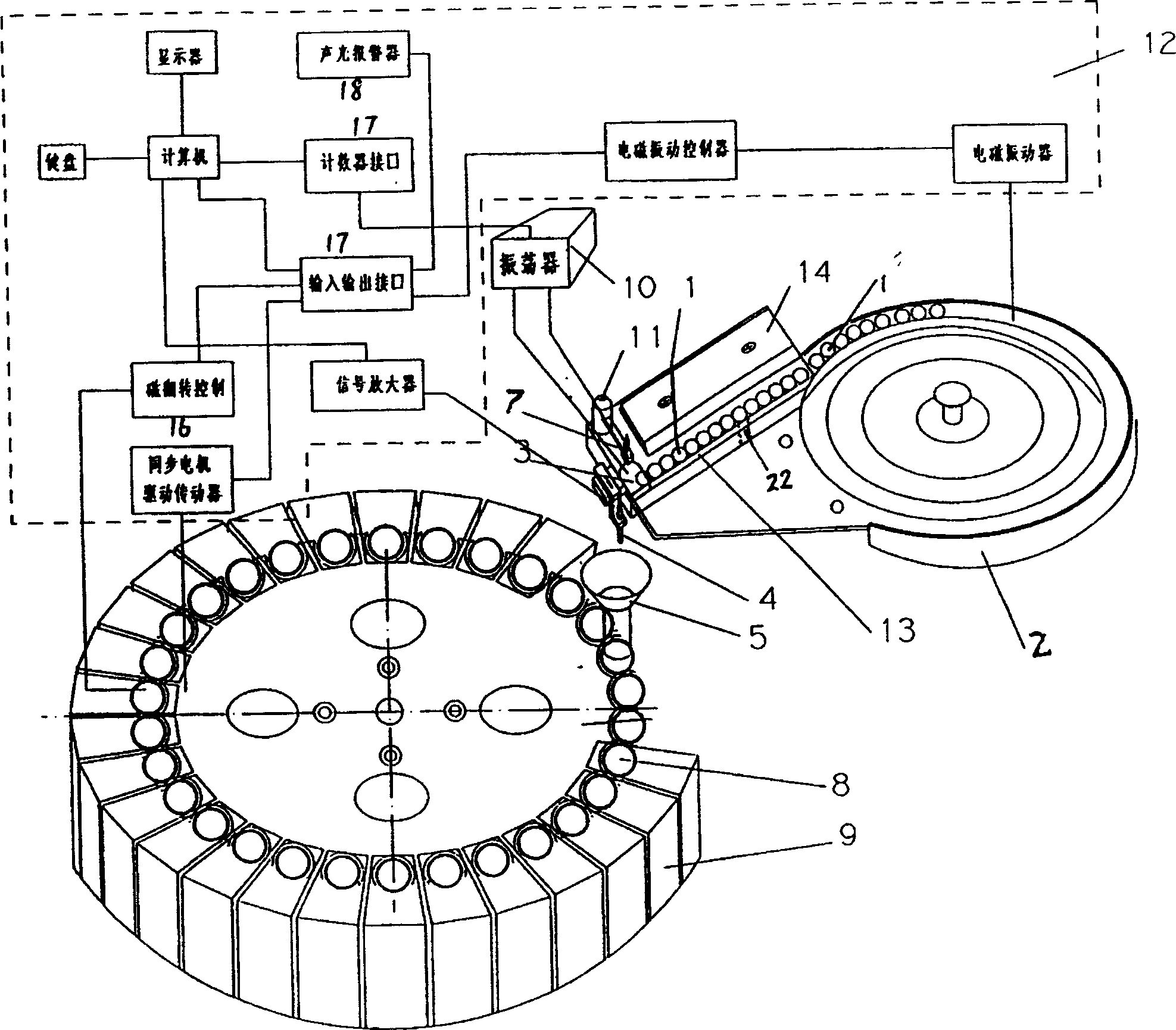

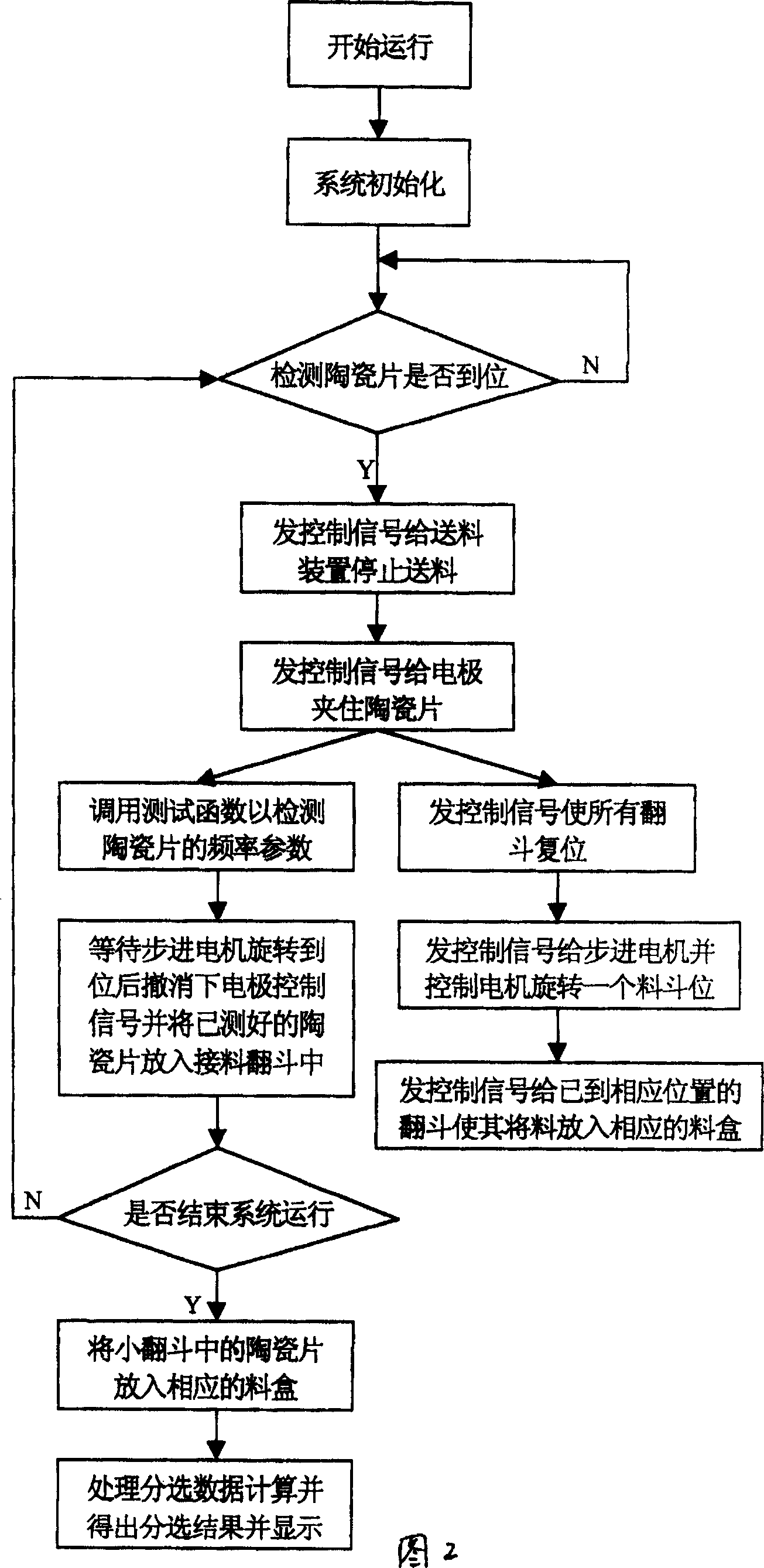

[0015] The electromagnetic oscillating tank transports the ceramic sheet or device 1. The test of the ceramic sheet is to contact the two sides of the ceramic sheet with the counter electrode, and the device test is to contact the lead-out electrode with the counter electrode. The electromagnetic oscillating tank includes a circular oscillating tank 2 and a flat oscillating tank 3 , the material is fed to the flat vibration platform by the electromagnetic vibration screw, and the flat vibration tank 3 is slightly inclined, and the horizontal vibration feeds the material to the position measurement. Set a flat vibrating platform to fix the flat oscillating tank 3. When testing the ceramic chip, the ceramic chip moves in the flat oscillating tank 3. When testing the device, the lead-out electrode moves in the flat oscillating tank 3. Also be fixed with photoelectric switch and positioning optical fiber 7. The circular oscillation groove is also set on the circular vibration tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com