An automatic steel bar straight thread threading processing equipment and processing method

A technology of processing equipment and steel bar processing, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of long processing time, and achieve the effect of high processing efficiency, saving transportation costs, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

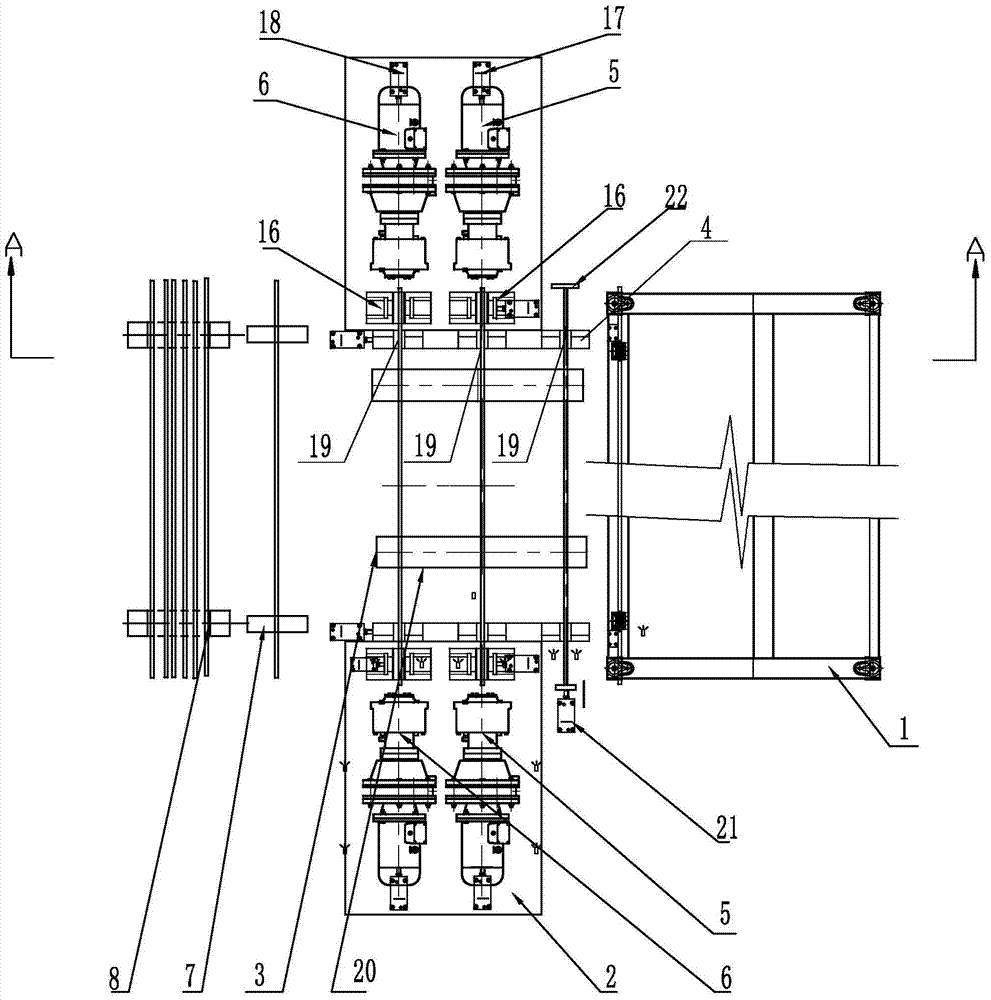

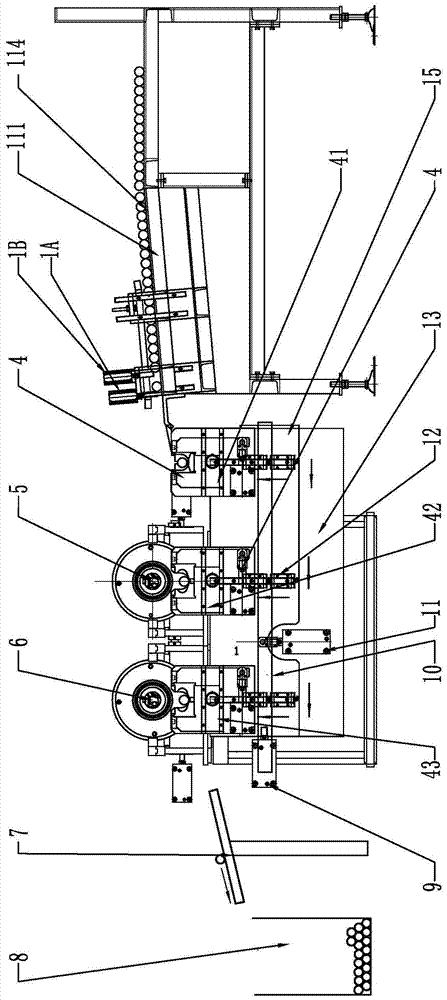

[0025] figure 1 Among them, an automatic steel bar straight thread threading processing equipment is characterized in that it is composed of a steel bar feeding bracket group 1, a steel bar rib stripping and rolling device 2, a steel bar processing bracket group 3 and a manipulator group 4; wherein, the steel bar feeding The bracket group 1 is located on one side of the steel bar rib stripping and thread rolling equipment 2; the manipulator group 4 is located on one side of the steel bar processing bracket group 3; the steel bar rib stripping and thread rolling equipment 2 consists of two steel bar car outer garden devices (5) Composed of two steel bar rolling devices 6, two steel bar car outer garden devices 5 and two steel bar thread rolling devices 6 are arranged opposite to each other, wherein the steel bar car outer garden device 5 and two steel bar thread rolling devices 6 are arranged in parallel, and the mechanism The whole is controlled by PLC.

[0026] The steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com