Fluorescent nano particle with AIE characteristic, bionic nano composite hydrogel actuator, preparation method and application

A composite hydrogel, fluorescent nanotechnology, applied in the field of fluorescent nanocomposite materials, can solve the problems of low contrast between nanoparticles and polymer matrix, difficult to achieve dynamic real-time detection, low conductivity, etc., to avoid complex sample processing, TICT Significant effect, significant color change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

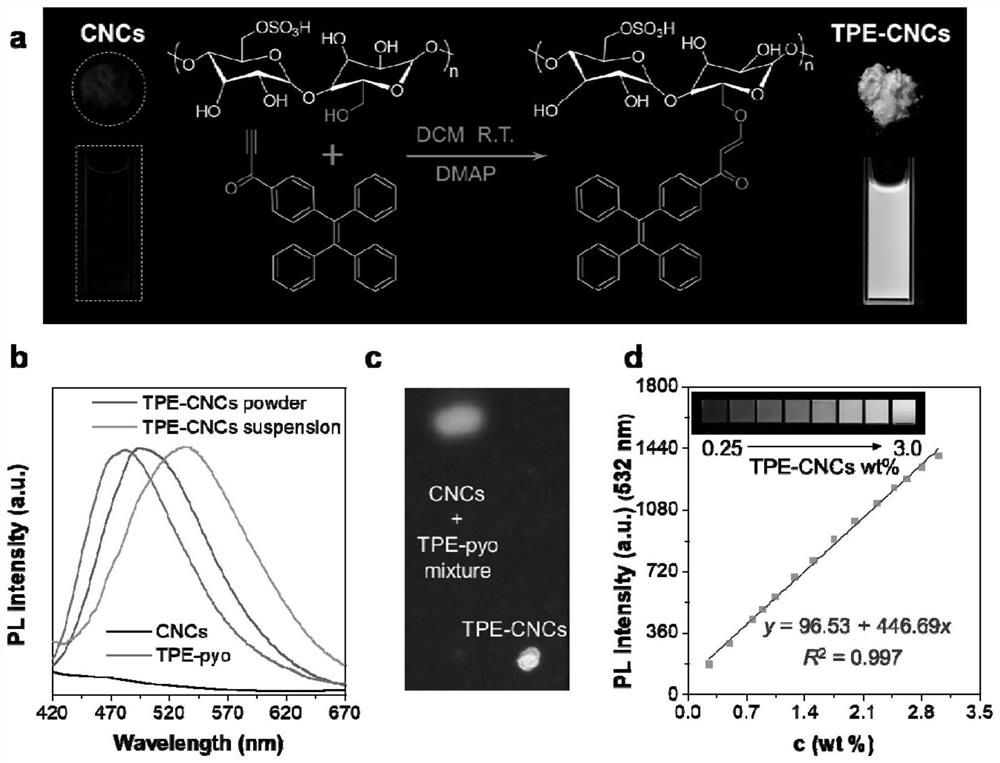

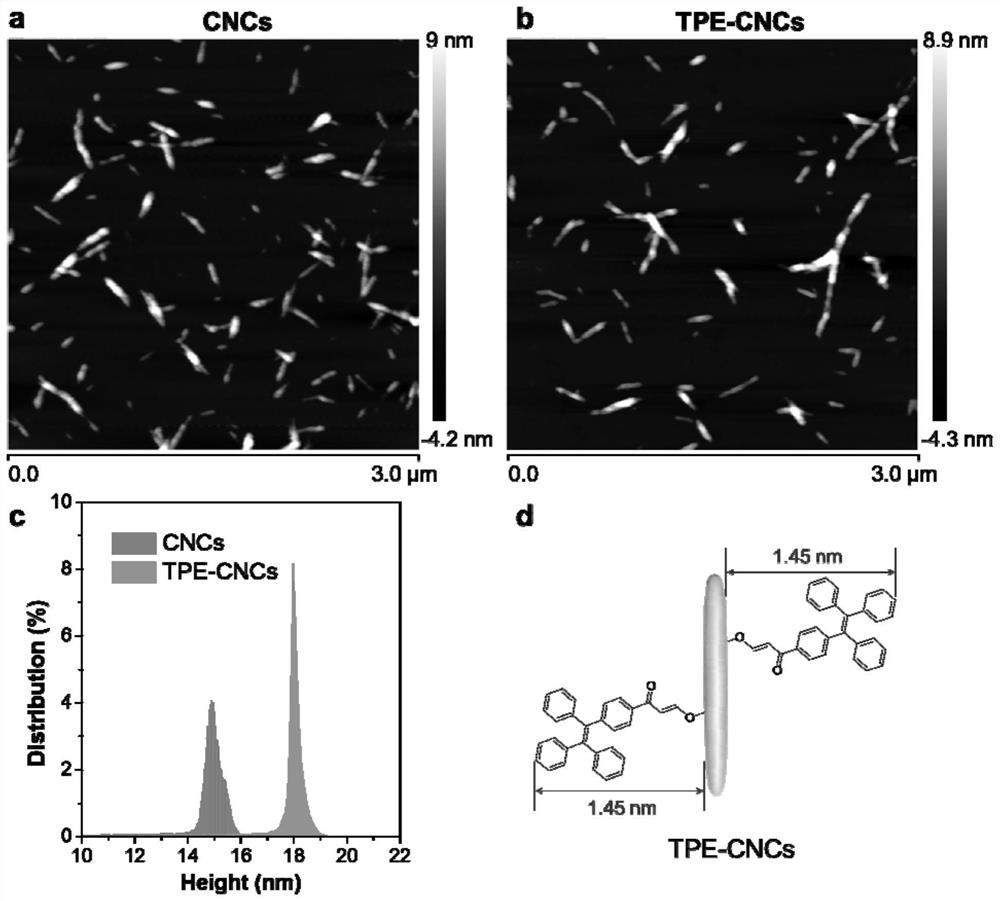

[0049] Example 1 Design and synthesis of fluorescent nanoparticle TPE-CNC

[0050] The TPE-pyo fluorescent molecules were grafted onto CNCs through click reactions to synthesize fluorescent nano-TPE-CNCs, such as figure 1 As shown in a, it specifically includes the following steps:

[0051] (1) Preparation of solution: dissolve 10-30mg TPE-pyo fluorescent molecule (alkyne-TPE) in 10-30mL CH 2 Cl 2 In the solvent, 0.1-0.4g cellulose nanocrystals (Cellulose Nanocrystal, CNC) were dispersed in 10-90mL CH 2 Cl 2 medium, sonicate for 10-40min, dissolve DMAP (4-dimethylaminopyridine) in CH 2 Cl 2 A solution of 20 mg / mL was obtained in , wherein the TPE-pyo fluorescent molecule and the CNC chemical structural formula are as follows:

[0052]

[0053] (2) Mix the prepared 0.5-4 mL DMAP solution with the TPE-pyo solution, dropwise into the CNC suspension while stirring, and stir for 12 h at room temperature to fully react;

[0054] (3) after the reaction finishes, the obtaine...

Embodiment 2

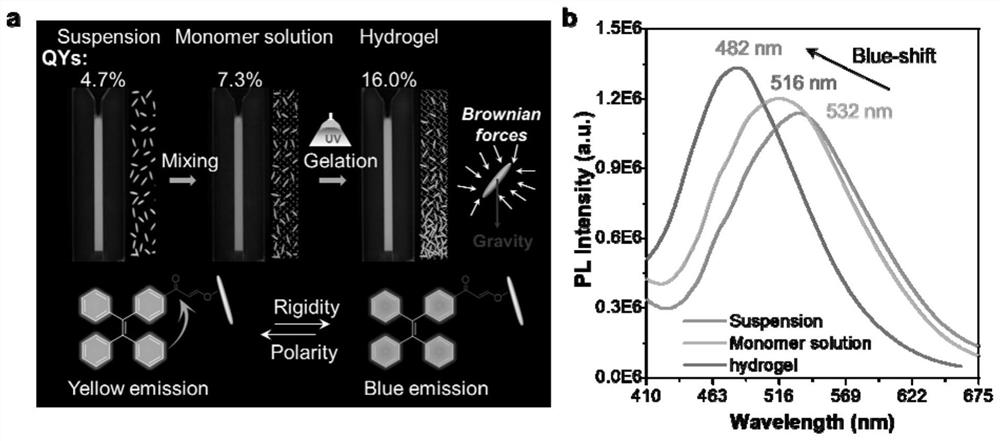

[0056] Example 2 Preparation of biomimetic nanocomposite hydrogel actuators

[0057] The TPE-CNC fluorescent nanoparticles were introduced into the composite hydrogel system to prepare a biomimetic nanocomposite hydrogel actuator (TPE-CNC nanocomposite hydrogel fiber), including:

[0058] Disperse 0.02-0.06g TPE-CNC into 2mL H 2 O, sonicate for 3min, add 0.1-0.3g N-isopropylacrylamide (NIPAM), 0.001-0.004g N,N'-methylenebisacrylamide (Bis), 10-40μL polyethylene glycol monoethyl ether Methacrylate (PEGMEMA), 2-6 μL of photoinitiator DEAP, stirred at room temperature in the dark for 10-60 min. The above solution is poured into the fiber mold, and the polymerization is initiated by ultraviolet light for 10-60 min to obtain the TPE-CNC nanocomposite hydrogel fiber. in, image 3 It is shown that during the preparation process, the fluorescence color and luminescence intensity of TPE-CNC are changed in different microenvironments. The fluorescent color of CNC gradually changed f...

Embodiment 3

[0059] Example 3 Tracking the dynamic motion and static distribution process of fluorescent nanoparticles in the hydrogel preparation process:

[0060] The TPE-CNC hydrogel precursor dispersion was continuously scanned by a fluorescence spectrometer ( Figure 4 ), the excitation wavelength was set to 350-400 nm, the scanning range was 400-800 nm, and the slit was set to 1 nm. The cuvettes used were 750 μL microcuvettes with an optical path length of 2 mm. In order to ensure uniformity, the samples were fully mixed before the test. The test was carried out at room temperature, and the fluorescence spectrometer and the sample were not disturbed. The test time is more than 400min. As time goes by, the fluorescence intensity of the sample first increases and then decreases, because the fluorescent nanoparticle TPE-CNC first aggregates between particles in the hydrogel dispersion system, and then continuously settles under the action of gravity. At the same time, due to the combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com