Innocent treatment system and method for organic solid waste with residual plant source pathogenic bacteria

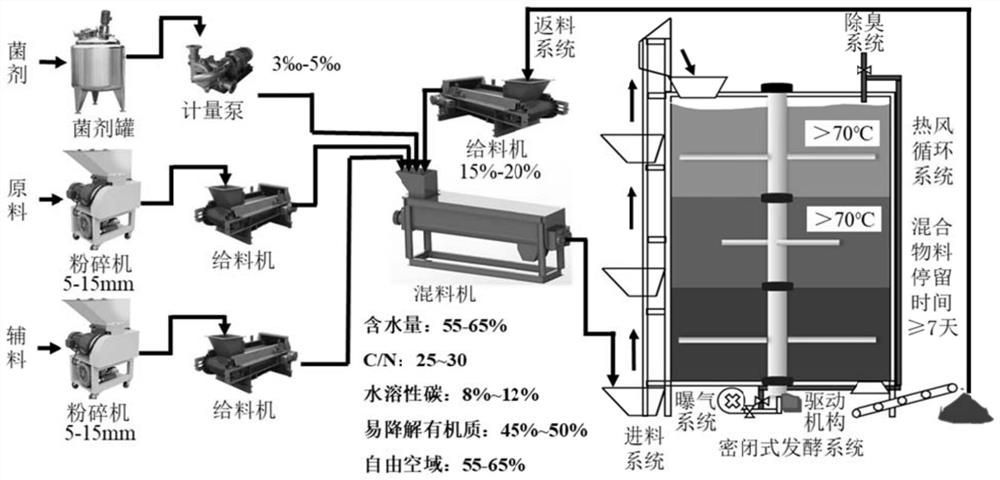

A technology for harmless treatment of organic solids, applied in the field of solid waste recycling, which can solve the problems of difficult to achieve effective inactivation of pathogenic microorganisms, safety risks, and fermentation failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

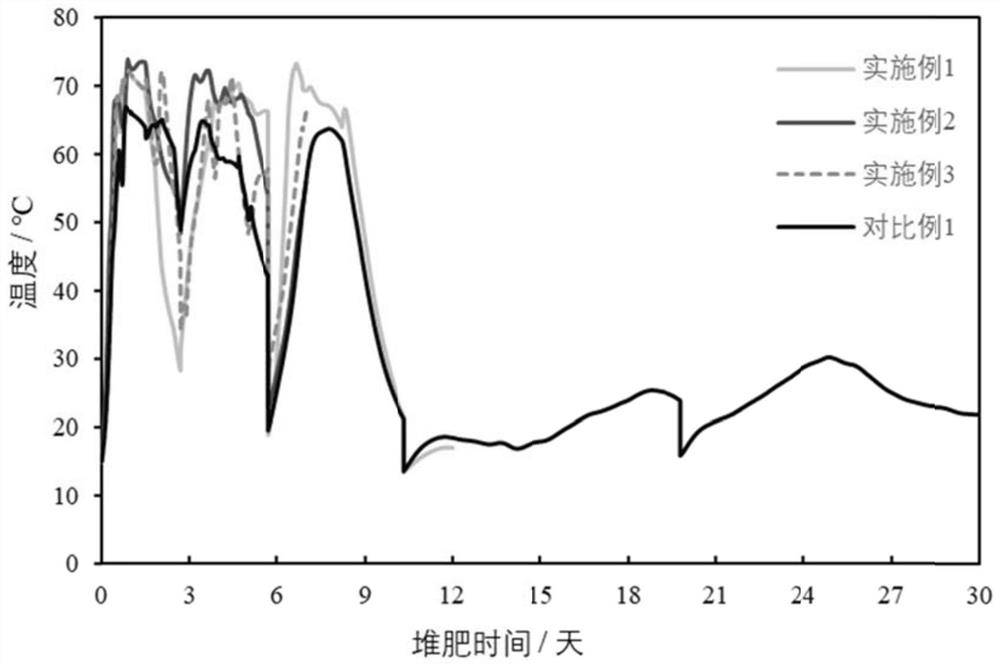

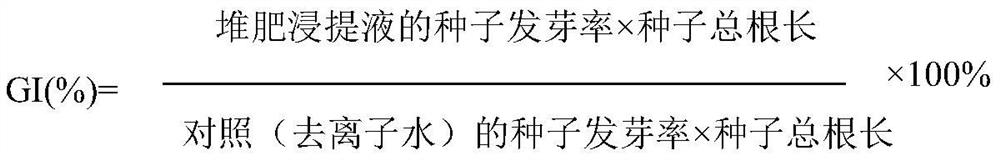

[0036] Take vegetable waste as the main material, take appropriate crop straw and livestock and poultry feces as an auxiliary materials, adjust the particle size of the material to 5-15mm; adjust the matching parameters according to the appropriate C / N and the moisture content, and complete the initial material mixing after the initial material mixes The free airspace of the initial material is set to 65 %, the water -soluble carbon content is 12 %, the biodegradable organic matter content is 55 %, the proportion of the addition of the bacteria is 3 ‰ of the mixed material quality (the bacteria agent is VT1020, purchased from the Wo earth world and earth Biological Technology Co., Ltd). Add the mixed material to the reactor, and perform a 12-day compulsory ventilation at room temperature at a temperature of 15-20 ° C (the ventilation rate is 0.2L · min -1 · Kgdm -1 ) The biological conversion process under the condition is performed on the 3rd and 7th days. At the same time, the m...

Embodiment 2

[0044] Take vegetable waste as the main material, take appropriate crop straw and livestock and poultry feces as an auxiliary materials, adjust the particle size of the material to 5-15mm; adjust the matching parameters according to the appropriate C / N and the moisture content, and complete the initial material mixing after the initial material mixes The free airspace of the initial material is set to 60 %, the water -soluble carbon content is 10 %, the biodegradable organic matter content is 50 %, the proportion of bacteria added to the mixed material quality Biotechnology Co., Ltd.). Add the mixed material to the reactor, and the 7-day mandatory ventilation at room temperature at a temperature of 15-20 ° C (the ventilation rate is 0.15L · min -1 · Kgdm -1 ) The biological conversion process under the condition is about 60 % of the water content on the third day.

[0045] According to the biological conversion process performed above, the temperature has reached 73.2 ° C on the s...

Embodiment 3

[0048] Take vegetable waste as the main material, take appropriate crop straw and livestock and poultry feces as an auxiliary materials, adjust the particle size of the material to 5-15mm; adjust the proportion parameters according to the appropriate C / N and moisture content, and complete the initial material mixing After that, the free airspace of the initial material was set to 65 %, the water -soluble carbon content was 12 %, the biodegradable organic matter content was 55 %, the proportion of the fungus added to the mixed material quality Tiandi Biotechnology Co., Ltd.). Add the mixed material to the reactor, and the 7-day mandatory ventilation at room temperature at a temperature of 15-20 ° C (the ventilation rate is 0.2L · min -1 · Kgdm -1 ) The biological conversion process under the condition is about 60 % of the water content on the third day.

[0049] According to the biological conversion process performed above, the temperature has reached 72.8 ° C on the second day, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com