Battery pack high and low temperature control system

A control system, high and low temperature technology, used in battery/fuel cell control devices, secondary batteries, secondary battery repair/maintenance, etc. The problem is to eliminate the superimposed temperature increase, prevent damage to the cell, and prevent serious attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

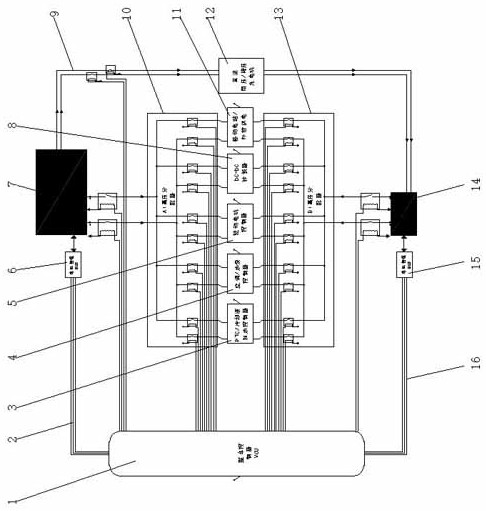

[0018] Example 1, refer to figure 1 , Before using the vehicle in a low temperature environment, remotely start the vehicle controller 1 through the APP to control the discharge operation of the secondary battery pack 14. The secondary battery pack 14 supplies power to the cooling / heating controller 3 on the vehicle through the high-voltage distributor 13, so as to realize the power supply to the main battery. The battery pack 7 is heated, and when the temperature of the main battery pack 7 reaches a temperature suitable for work, the vehicle preheating is completed; when using the car, the main battery pack 7 can be directly controlled to drive the car;

Embodiment 2

[0019] Example 2, refer to figure 1 , if the vehicle needs to be driven immediately at low temperature, the auxiliary battery pack 14 can directly drive the vehicle;

Embodiment 3

[0020] Example 3, refer to figure 1 , when the vehicle is running at high speed, the output current of the main battery pack 7 is large, and the temperature of the main battery pack 7 rises. The vehicle controller 1 determines whether the current temperature of the main battery pack 7 collected by the main battery pack BMS6 in real time is higher than that of the main battery pack. The maximum protection temperature set by 7; if it is judged that the main battery pack 7 reaches the critical value of the maximum protection temperature, the vehicle controller 1 controls the auxiliary battery pack 14 to supply power to the cooling / heating controller 3, and the main battery pack 7 cools down. At the same time, it supplies power to other on-board equipment to reduce the power output of the main battery pack 7. After the main battery pack 7 cools down, switch to the main battery pack 7 to supply power for the on-board equipment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com