Pipe fitting bulging method and device adopting metal coating magnetic collector

A metal coating and magnetic collector technology, which is applied in the field of tube bulging methods and devices, can solve the problems of large skin depth of the magnetic collector, changing the structure of the magnetic collector, and complicated packaging process, so as to avoid product defects and achieve good overall uniformity , the effect of reasonable magnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

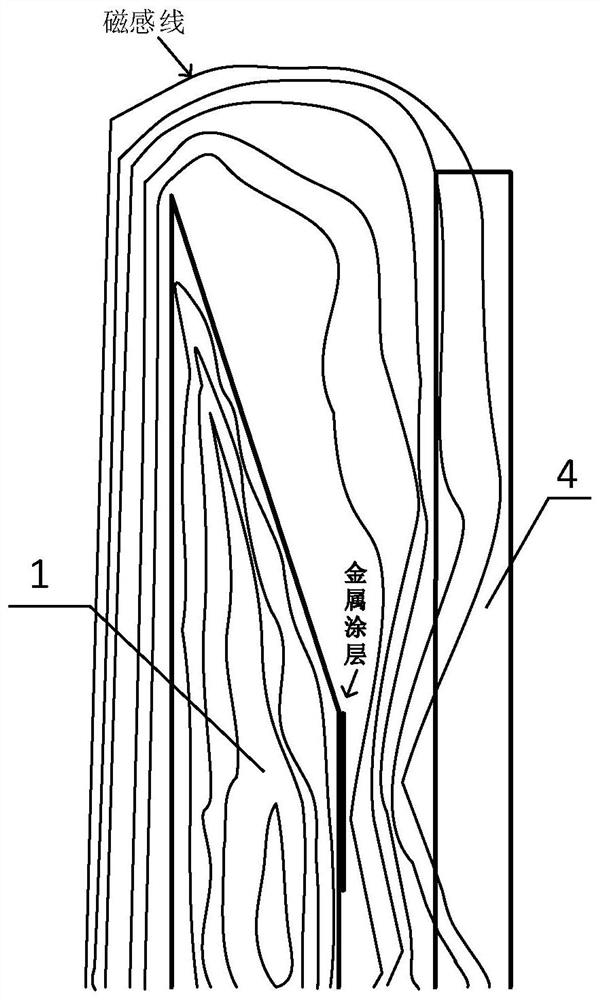

[0043] The pipe bulging method of the embodiment controls the distribution of the induced current on the outer surface of the magnetic collector by using metal coatings with different thicknesses during the pipe bulging process, and the thickness of the metal coating is less than the skin depth, so as to reduce the skin effect and increase the Workpiece forming quality and forming efficiency.

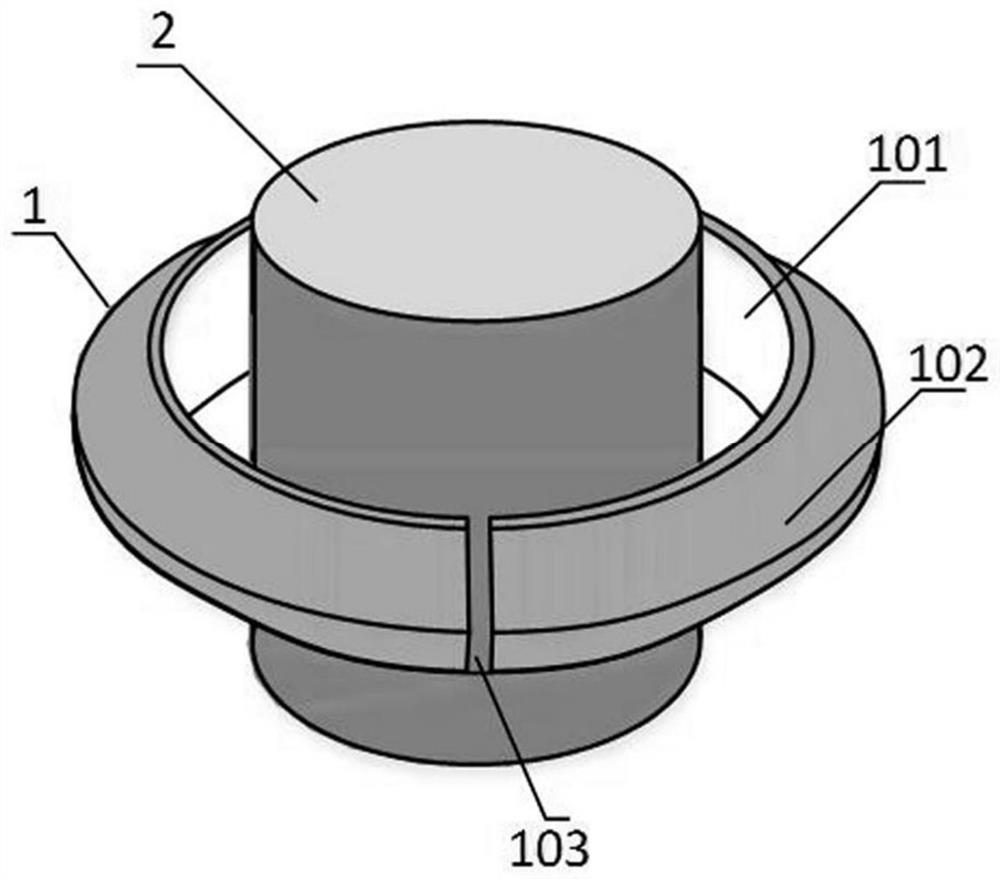

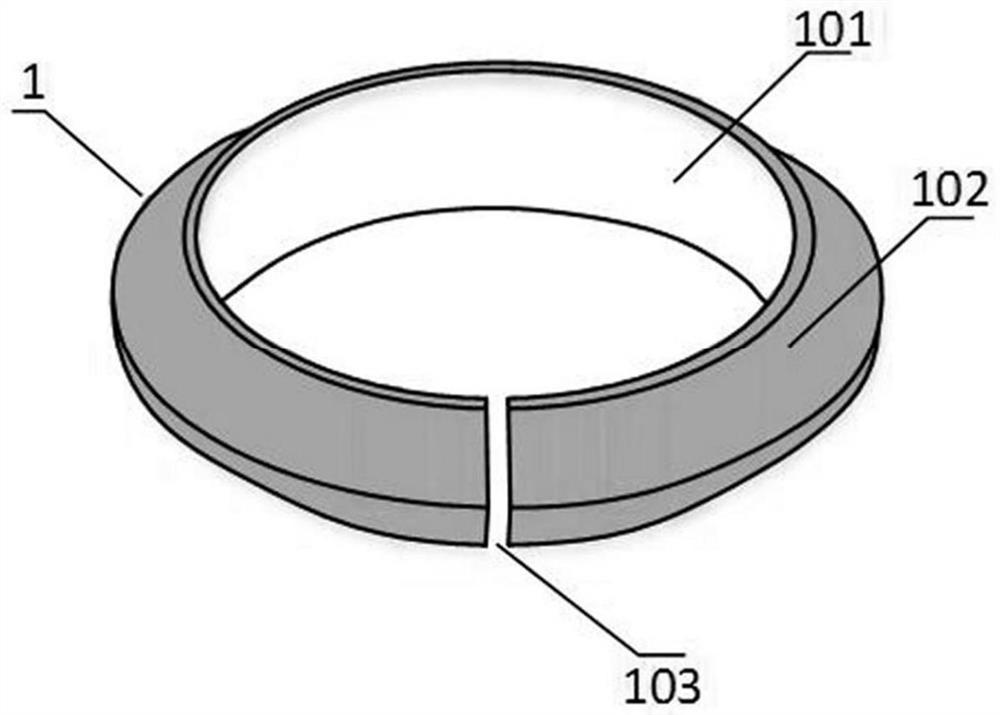

[0044] like figure 1 and figure 2 As shown, the magnetic collector 1 includes an insulating ring 101 and a metal coating 102 on the outer surface of the insulating ring. The insulating ring 101 is provided with a slit 103; the cross section of the magnetic collector 1 is an isosceles trapezoid. The metal coating 102 is a copper coating. The angle formed by the slit of the magnetic collector and the center line of the magnetic collector is 1.2°.

[0045] The pipe bulging method includes the following steps:

[0046]Step 1: Calculate the reference value of the skin depth of the magne...

Embodiment 2

[0062] like figure 2 As shown, the metal-coated magnetic collector includes an insulating ring 101 and a metal coating 102 on the outer surface of the insulating ring. The insulating ring 101 is provided with a slit 103; the cross-section of the metal-coated magnetic collector is trapezoidal. The angle formed by the slit 103 of the metal-coated magnetic collector and the center line of the magnetic collector is 0.5°-1.5°.

[0063] The metal-coated magnetic collectors of the embodiments are used in a pipe bulging process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com