Vinyl chloride resin composition and molded article

A technology of vinyl chloride resin and composition, which is applied in the field of vinyl chloride resin composition, can solve problems such as fogging, heat aging resistance, plasticizer transfer, etc., and achieve improved printability, excellent flexibility, and mixed Excellent refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0103]Hereinafter, the present invention will be specifically described with reference to Examples and the like, but the present invention is not limited to these Examples. In addition, in the production examples shown below, the monomers and other compounds were dried and purified by a conventional method, and were used by degassing with nitrogen gas. In addition, the transport and supply of monomers and other compounds to the reaction system were performed under a nitrogen atmosphere. In addition, various physical properties of Examples and Comparative Examples were measured or evaluated by the following methods.

[0104] In the following examples, the weight average molecular weight (Mw) and the number average molecular weight (Mn) of the acrylic block copolymer were obtained by GPC in terms of molecular weight in terms of polystyrene, and the molecular weight distribution (Mw / Mn) was calculated from these values. The measurement apparatus and conditions used in GPC are as...

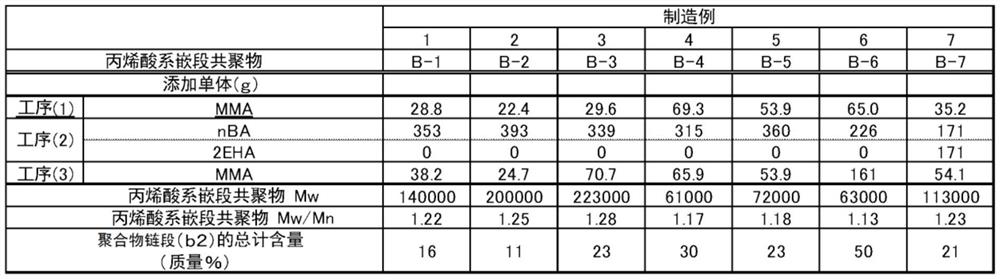

manufacture example 2~7

[0157] Acrylic acid was produced in the same manner as in Production Example 1, except that the addition amounts of the monomers in the steps (1) and (3), and the types and addition amounts of the monomers in the step (2) were changed as shown in Table 1. Block copolymers (B-2) to (B-7).

[0158] [Table 1]

[0159]

[0160] MMA: methyl methacrylate

[0161] nBA: n-butyl acrylate

[0162] 2EHA: 2-ethylhexyl acrylate

[0163] In addition, in the Example and the comparative example, the following thing was used as each component used for the vinyl chloride resin composition.

[0164] Vinyl chloride resin (A): Shin-Etsu Chemical Co., Ltd. product, "TK-1000" (average degree of polymerization 1000)

[0165] ·Gelling accelerator (C-1): "METABLENP550A" manufactured by Mitsubishi Chemical Corporation

[0166] ·Gelling accelerator (C-2): "METABLENP530A" manufactured by Mitsubishi Chemical Corporation

[0167] Plasticizer: Tokyo Chemical Industry Co., Ltd., "DINP"

[0168] Plas...

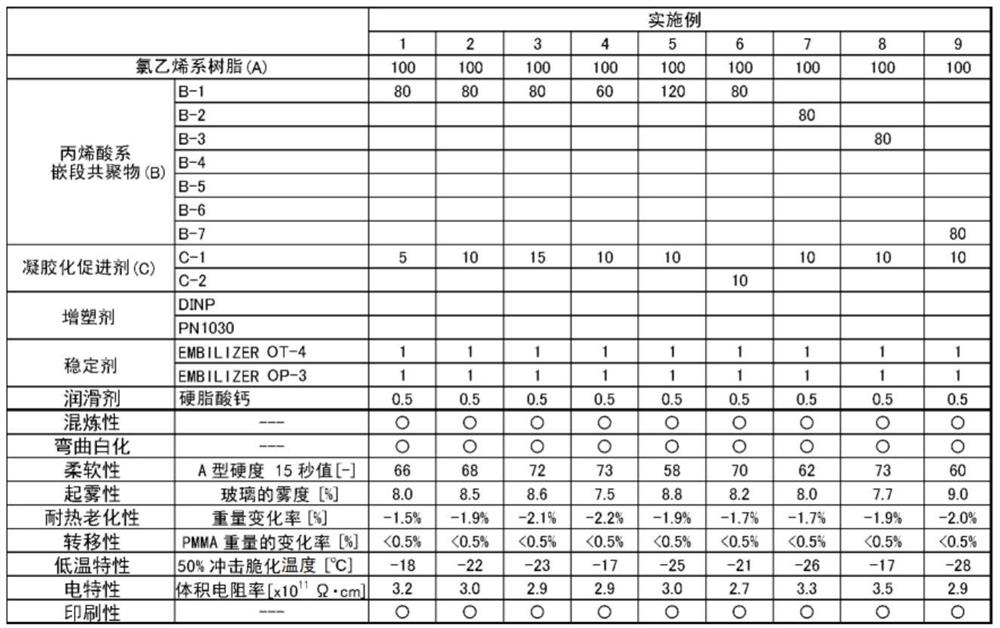

Embodiment 1

[0173] As shown in Table 2, 80 parts by mass of the acrylic block copolymer (B-1) shown in Table 1 and 5 parts by mass of the gelation accelerator were mixed with 100 parts by mass of the vinyl chloride resin using a Henschel mixer. parts, 1 part by mass of stabilizer, and 0.5 part by mass of lubricant, and were stirred and mixed for 5 minutes to obtain a raw material mixture. Next, the raw material mixture was kneaded with twin rolls heated to 160° C. for 5 minutes under the conditions described in the item of kneading property to obtain a vinyl chloride-based resin composition. The obtained vinyl chloride-based resin composition was press-molded under the conditions described in the item of kneadability, and a 2-mm-thick pressed tablet and a 1-mm-thick pressed tablet were produced. Using the obtained compressed tablets, kneading properties, bending whitening properties, flexibility, fogging properties, heat aging resistance, transfer properties, low-temperature properties, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com