Steel rail damage determination method and determination system based on convolutional neural network

A technology of convolutional neural network and determination method, which is applied in the field of rail damage determination method and determination system based on convolutional neural network, which can solve problems such as low efficiency and large manual investment, and achieve the effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

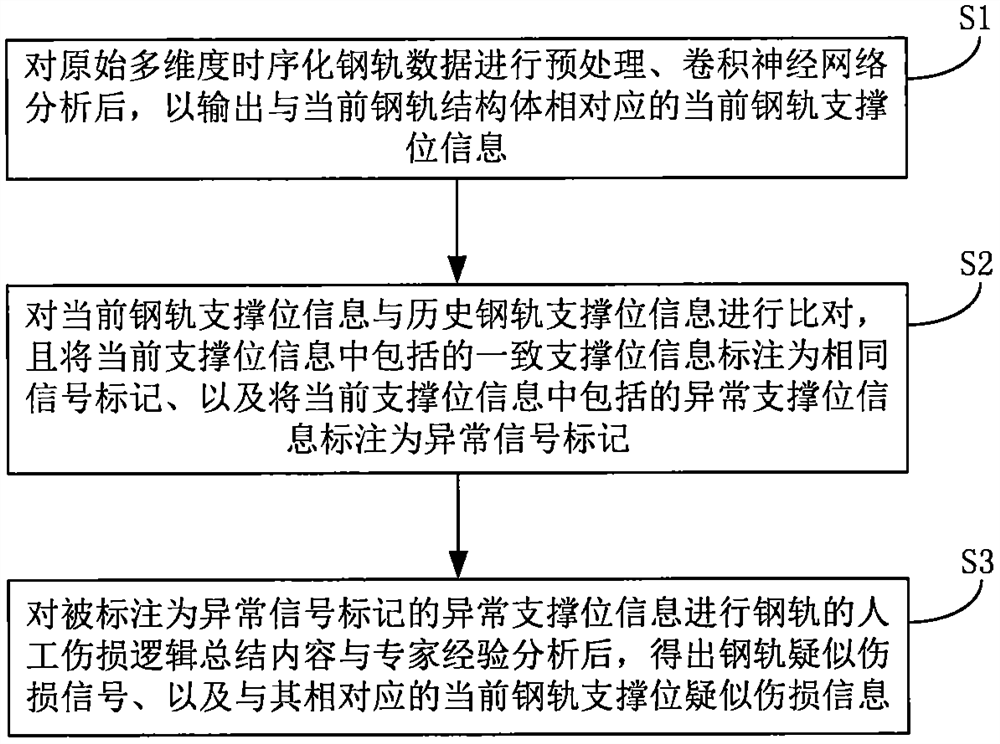

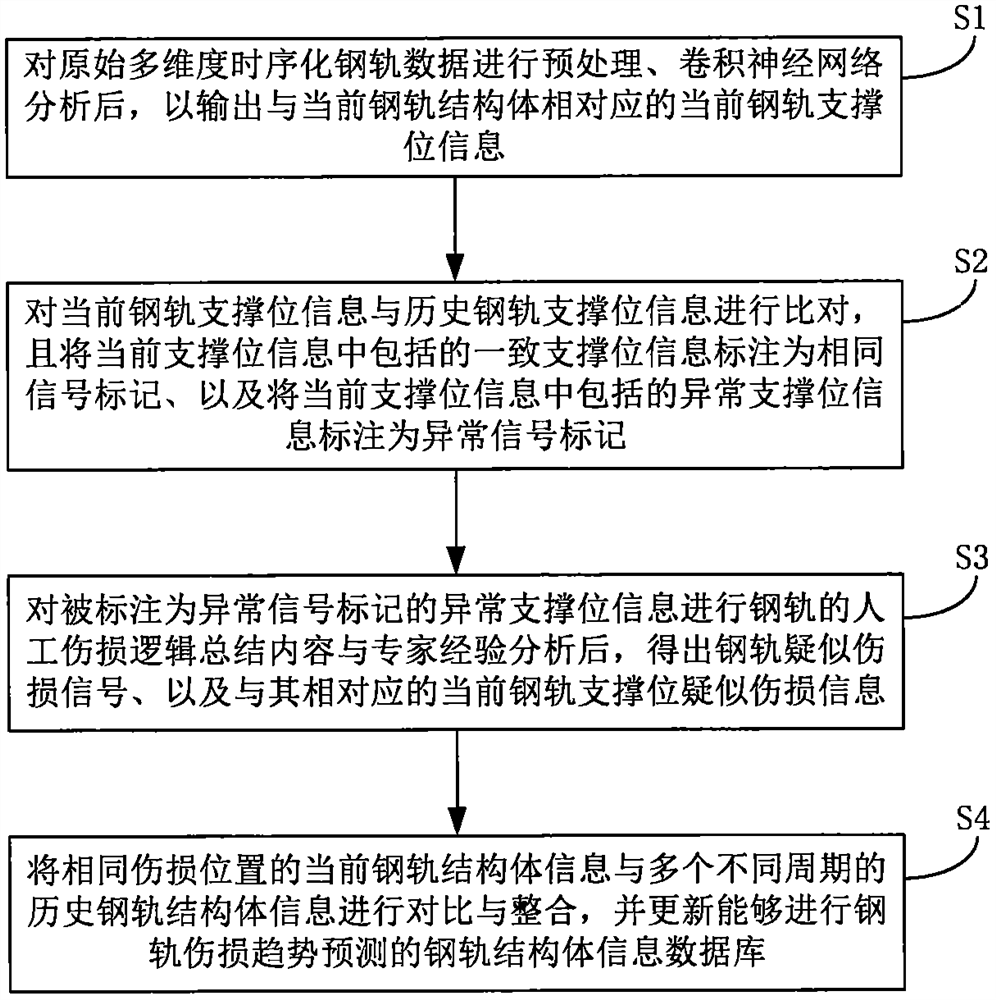

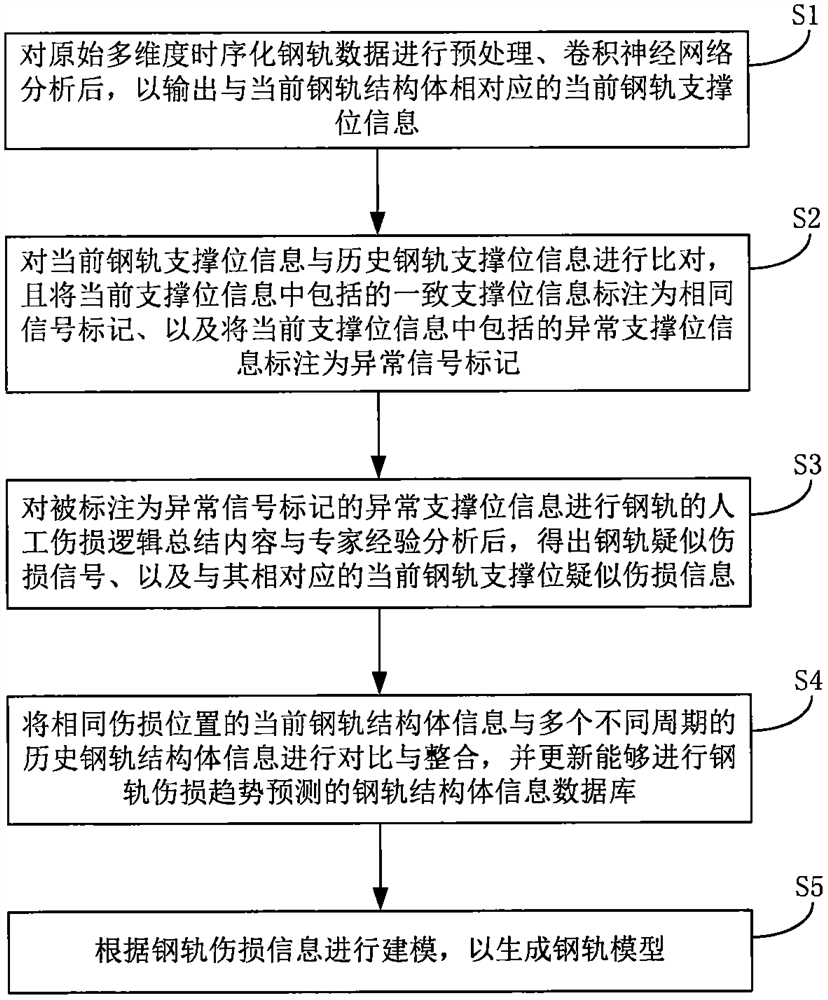

Method used

Image

Examples

Embodiment 1

[0043] The structured data of the probe channel is formed after training on the raw multi-dimensional time-series rail data.

[0044] S111 , after screening the original multi-dimensional time series rail data, artificially mark the support segment for the data type.

[0045] Wherein, in step S111, after screening the original multi-dimensional time series rail data, a sliding window of 60 steps is used to manually mark the data type.

[0046] The support segment annotation types include: support reinforcement position, support aluminothermic welding position, support base metal position, support switch position, support tip rail position, and support noise position.

[0047] S112. Perform matrix processing on the artificially marked support bit segment data, and form structured data of the probe channel after processing and processing through one-hot encoding.

[0048] The original multi-dimensional time series rail data is the rail data collected by the rail flaw detection ...

Embodiment 2

[0050] S11. After inferring the original multi-dimensional time series rail data, the structured data of the probe channel is formed.

[0051] S111. After expanding the original multi-dimensional time series rail data, filter out invalid data, and perform fixed-length interception on the retained valid data;

[0052] S112 , performing matrix processing on the intercepted fixed-length data, and forming structured data of the probe channel after processing and processing through one-hot encoding.

[0053] The original multi-dimensional time series rail data is the rail data collected by the rail flaw detection trolley.

[0054] S12, the convolutional neural network analyzes the structured data of the probe channel to output current rail support position information corresponding to the current rail structure.

[0055] In step S12, the convolutional neural network is divided into a data augmentation layer, a feature construction layer and a target classification layer, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com