Insoluble scale dispersing and unblocking system and use method thereof

A kind of insoluble scale and dispersion technology, which is applied in the direction of chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of oil and water well scaling and blockage, formation cuttings loosening and falling off, and limited effect, so as to avoid The effect of secondary blockage, avoiding loosening and falling off, and improving production level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

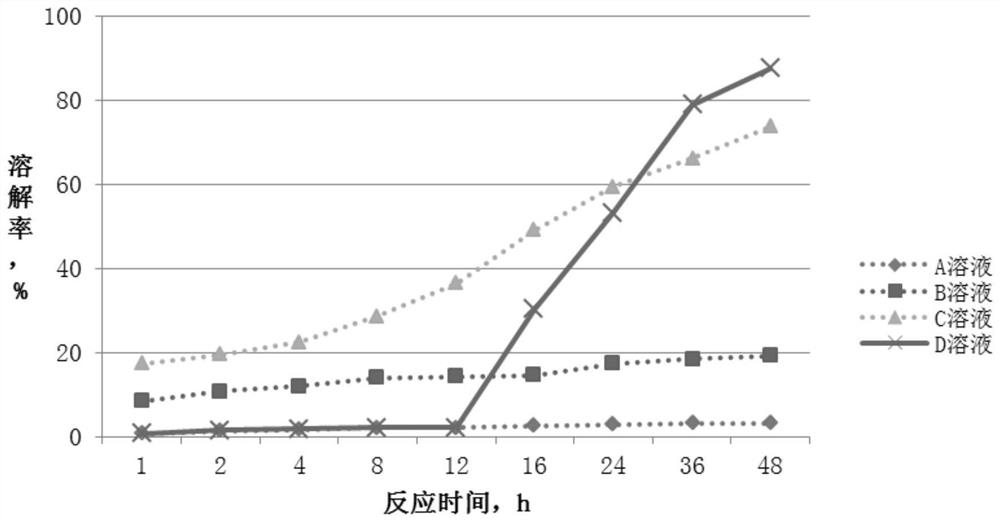

Embodiment 1

[0031] Insoluble scale dispersion and blockage removal system, including:

[0032] The first slug is cleaning fluid, including diesel and limonene with a mass ratio of 8:2;

[0033] The second slug is a fatty alcohol polyoxyethylene ether solution with a mass concentration of 0.5%:

[0034] The third slug is a treatment liquid with a mass concentration of 15%. In terms of weight components, the treatment liquid includes 17 parts of phosphine-based hydrolyzed polymaleic anhydride (phosphine-containing hydrolyzed polymaleic anhydride), aminotrimethylenephosphonic acid 10 parts potassium, 8 parts tetrasodium glutamic acid diacetate, 4 parts tripotassium citrate, 1.5 parts sodium tartrate;

[0035] The fourth slug is a potassium chloride solution with a mass concentration of 1%;

[0036] Injection volume Among them, r is the treatment radius, m; h is the thickness of the reservoir production section, m; is the porosity, %, where the treatment radius corresponding to the inje...

Embodiment 2

[0045] Insoluble scale dispersion and blockage removal system, including:

[0046] The first slug is cleaning fluid, including diesel and limonene with a mass ratio of 10:2;

[0047] The second slug is a fatty alcohol polyoxyethylene ether solution with a mass concentration of 0.6%:

[0048] The third slug is a treatment liquid with a mass concentration of 16%. In terms of weight components, the treatment liquid includes 20 parts of phosphine hydrolyzed polymaleic anhydride, 12 parts of potassium aminotrimethylene phosphonate, and glutamic acid diacetic acid. 10 parts of tetrasodium, 6 parts of tripotassium citrate, 2 parts of sodium tartrate;

[0049] The fourth slug is a potassium chloride solution with a mass concentration of 1.2%;

[0050] Injection volume Among them, r is the treatment radius, m; h is the thickness of the reservoir production section, m; is the porosity, %, where the treatment radius corresponding to the injection amount of the first slug is 0.4m, t...

Embodiment 3

[0059] Insoluble scale dispersion and blockage removal system, including:

[0060] The first slug is cleaning fluid, including diesel and limonene with a mass ratio of 6:2;

[0061] The second slug is a 0.4% fatty alcohol polyoxyethylene ether solution:

[0062] The third slug is a treatment liquid with a mass concentration of 14%. In terms of weight components, the treatment liquid includes 15 parts of phosphine hydrolyzed polymaleic anhydride, 8 parts of potassium aminotrimethylene phosphonate, and glutamic acid diacetic acid. 5 parts of tetrasodium, 2 parts of tripotassium citrate, 1 part of sodium tartrate;

[0063] The fourth slug is a potassium chloride solution with a mass concentration of 0.8%;

[0064] Injection volume Among them, r is the treatment radius, m; h is the thickness of the reservoir production section, m; is porosity, %, where the treatment radius corresponding to the injection volume of the first slug is 0.6m, the treatment radius corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com