Preparation method of unilateral reaction type functional group terminated silicone oil

A reactive, functional group technology, applied in the field of preparation of unilateral reactive functional group-terminated silicone oil, can solve the problems of long equilibrium reaction time, affecting the use effect, and complicated solvent recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

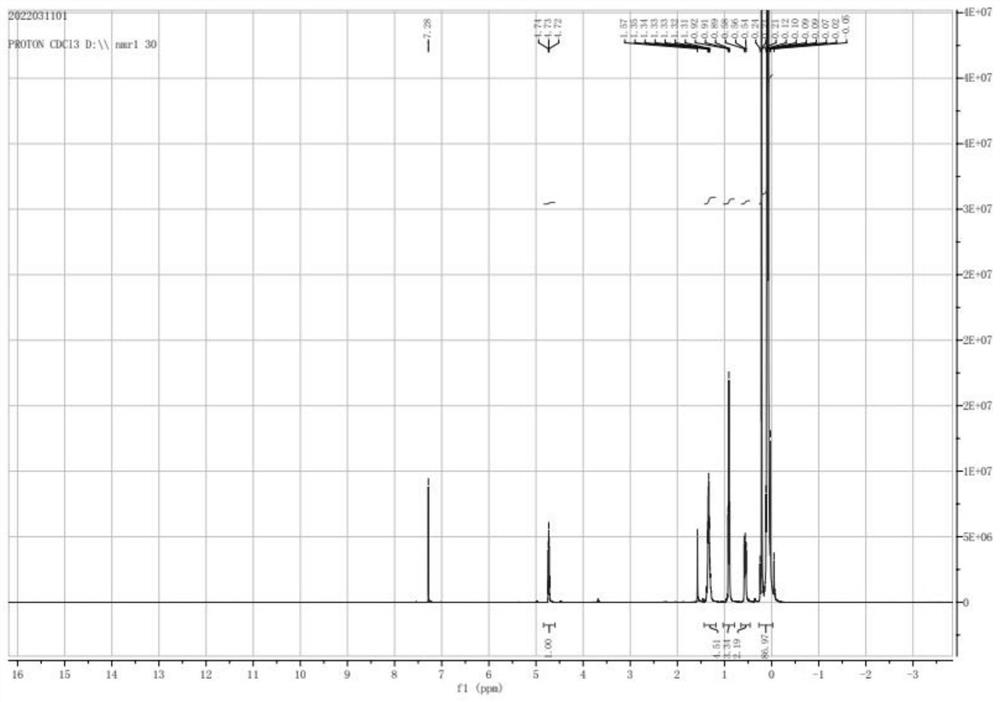

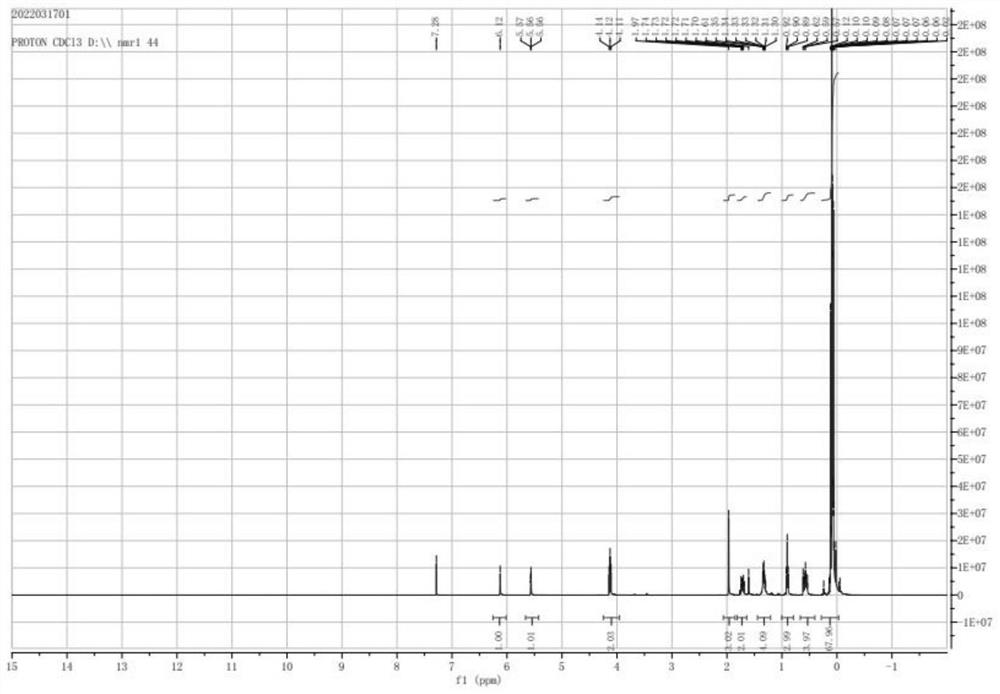

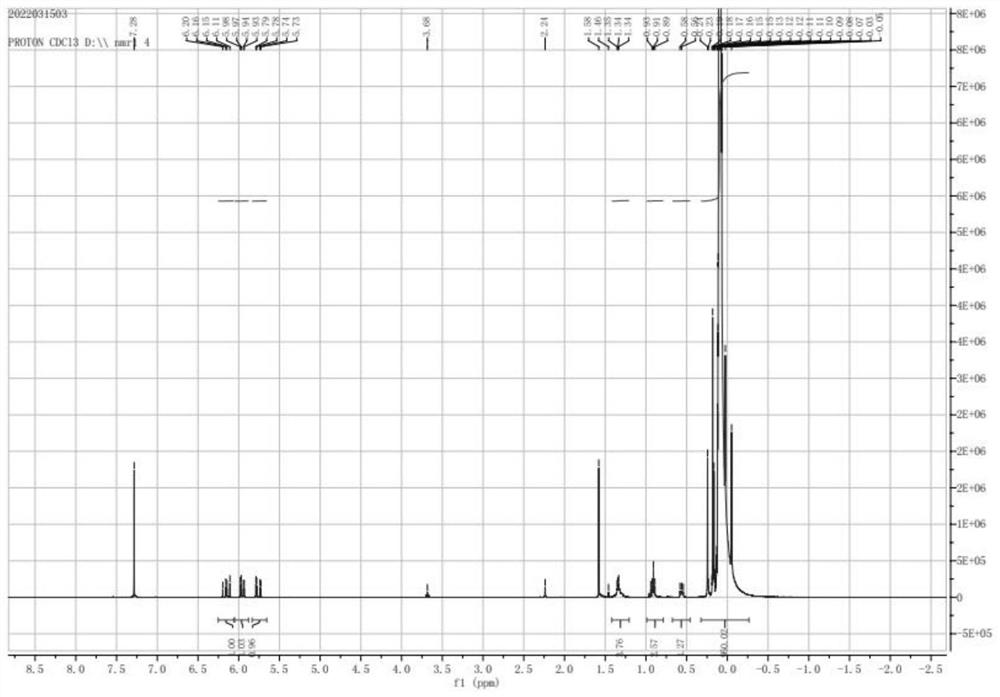

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

[0030] refer to figure 1 , a preparation method of unilateral reactive functional group-terminated silicone oil, which specifically comprises the following steps:

[0031] S1: Hexamethylcyclotrisiloxane (D3) 884g dissolved in 800g THF under nitrogen protection, set the flow rate of quantitative pump B to 28.06g / min, butyllithium 400mL nitrogen protection, set the flow rate of quantitative pump A to 4.53g / min, At the same time, turn on the two pumps A and B to pump the material into the premixer and then enter the microchannel reactor, set the reaction temperature to 0-5 degrees Celsius, enter the reactor B through the quantitative pump C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com