Preparation method of soybean protein composite gel food and product thereof

A technology of soybean protein and composite gel, which is applied in the directions of protein food ingredients, protein food processing, vegetable protein processing, etc., can solve the problems of lack of protein in nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

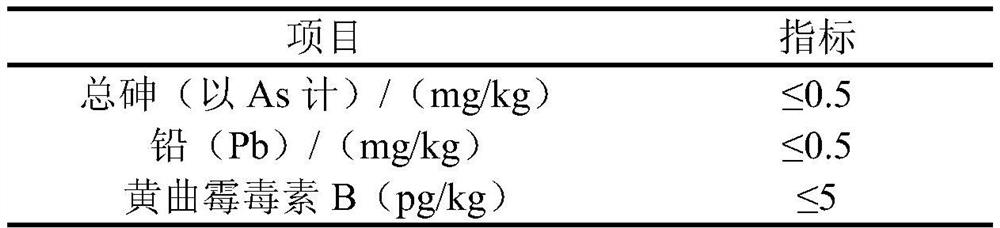

[0037] Table 1

[0038]

[0039] According to the composition ratio of Table 1, the preparation of soybean protein composite gel food was carried out:

[0040] (1) Disperse soybean protein isolate in water, add chitosan oligosaccharide and transglutaminase, and react with constant temperature shaking at pH 6 and 45°C for 3 hours. After the reaction is completed, inactivate the enzyme at 90°C for 5 minutes to obtain glycosyl soy protein;

[0041] (2) place the rice after cleaning and drying (embodiments 1~4 correspond to purple rice, yellow millet, sugar-controlled rice and germinated brown rice respectively) in a desktop ultrafine pulverizer (ST528) and grind, and the rotating speed 25000r / min, milled for 5min; the obtained rice flour was passed through a 200-mesh sieve, and the material under the sieve was taken for later use;

[0042] (3) get rice flour (any one in purple rice flour, yellow millet flour, sugar-controlled rice flour and germinated brown rice flour) and j...

Embodiment 5

[0050] Sensory evaluation criteria for products:

[0051] In order to directly reflect the quality of the product and obtain a better product, the sensory evaluation standard table of the product of the present invention is formulated according to the local standards and the sensory evaluation standards in the relevant literature. And invited 10 laboratory personnel to learn the evaluation terms of the products in the local standards, and carried out multiple scoring evaluation exercises. One hour before the formal evaluation, they did not smoke, eat, or use odorous cosmetics. Take appropriate samples and place them on white porcelain. In the plate, observe the color and impurities under natural light. After the tasting, rinse your mouth with warm water, and then try the next sample. According to the evaluation criteria in Table 4, the samples were individually scored for the color, appearance, mouthfeel, toughness, viscosity and taste of different samples.

[0052] Table 4 P...

Embodiment 6

[0060] Single factor experiment with different addition amounts of glycosylated cross-linked protein:

[0061] In order to determine the addition amount of soybean protein isolate after glycosylation and the addition ratio of rice flour, select 10g purple rice flour, 20ml pure water, add 2g, 2.5g, 3g, 3.5g, 4g of glycosylated protein respectively, and compound with purple rice flour After high-temperature aging, the product is scored and processed with reference to the sensory evaluation criteria in Table 4, and the optimum addition amount of glycosylated cross-linked protein is determined comprehensively. With the addition of glycosylated protein, the smell, toughness and appearance of the product did not change much, but the taste and color changed greatly, and with the addition of glycosylated protein, the sensory evaluation score first increased and then decreased. According to Table 6 It is concluded that when the added amount of soybean protein isolate per 10g of rice fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com