Three-phase copper bar structure of hybrid power motor

A technology of three-phase copper bars and hybrid power, applied in the direction of motors, circuits, coupling devices, etc., can solve problems such as noise, affecting the work of three-phase copper bars, loose parts of three-phase copper bars, etc., to ensure product reliability, The effect of low cost and compact row structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

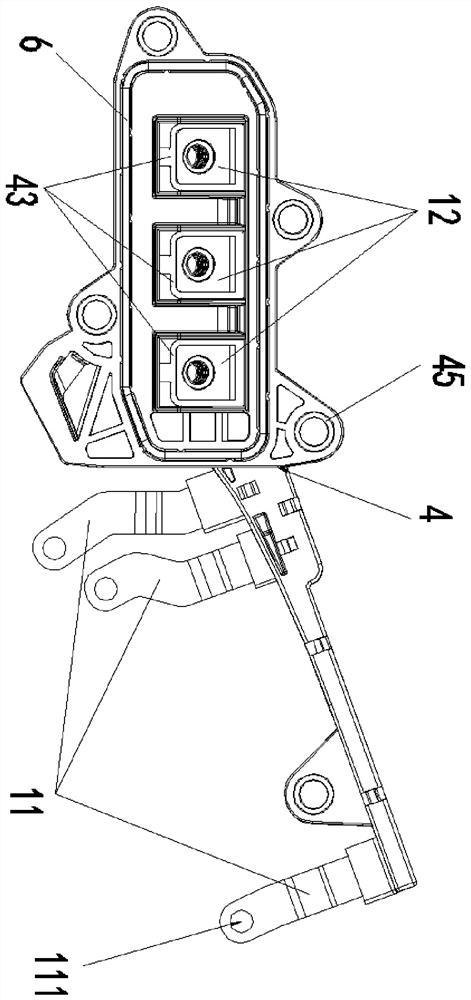

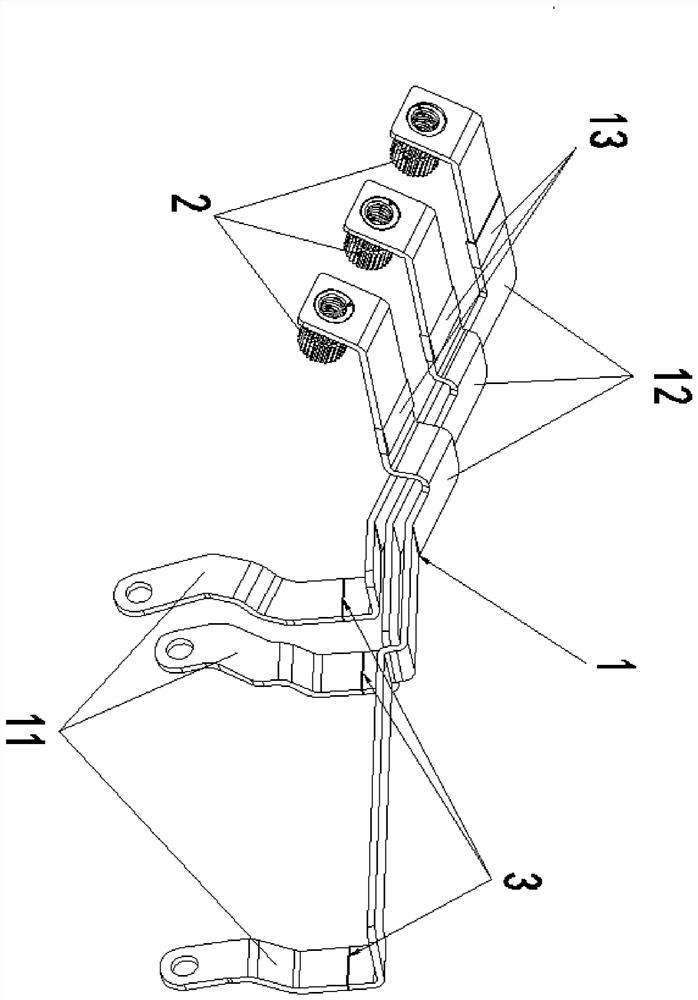

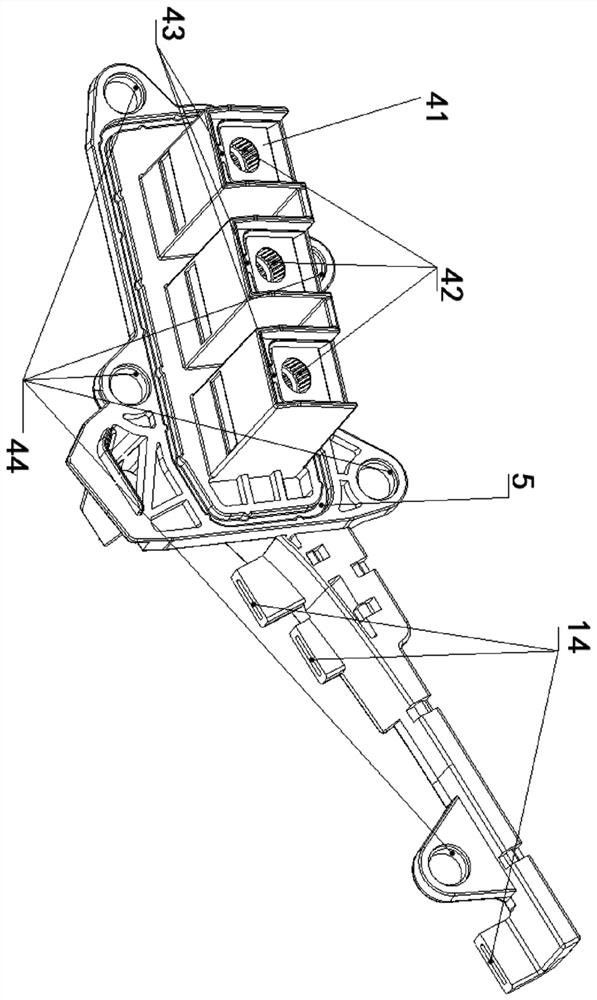

[0022] like Figure 1 to Figure 4 As shown, a three-phase copper bar structure of a hybrid motor includes: a copper bar assembly 1, the copper bar assembly 1 is composed of three soft copper bars 11 and three hard copper bars 12 welded and arranged respectively, the soft copper bars The extension end of the row 11 is provided with a connecting hole 111, the extension end of the hard copper bar 12 is provided with a blocking block 13, and the front end of the extension end of the hard copper bar 12 is riveted with a riveting hole, which is riveted into the riveting hole by a riveting machine. Press riveting thread insert 2, the thread insert 2 is provided with a blind hole with an inner thread recessed inward to avoid the molten material of the insulating shell 4 from blocking the thread, and the blind hole is manufactured according to the effective thread length of the fixing bolt. An insulating shell 4 is injection-molded on the part between the blocking blocks 13 at the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com