Lithium metal battery diaphragm as well as preparation method and application thereof

A lithium metal battery and diaphragm technology, applied in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as ignoring battery safety, lack of safety, and considerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]A preparation method of a lithium metal battery separator, comprising the following steps:

[0038] S1) using a wet process to prepare a modified polymer diaphragm filled with reinforcing materials, specifically adding reinforcing materials and additives to the polymer resin material in proportion and mixing them sufficiently, and melting the mixture at high temperature and extruding it into a film, Stretching and extraction steps to obtain a modified polymer diaphragm filled with reinforcing materials;

[0039] S2) The lithium metal battery separator is formed by attaching the lithiophilic material to the side of the modified polymer separator filled with the reinforcing material by using a physical deposition method.

[0040] A lithium metal battery includes a lithium metal battery separator, and a lithiophilic material layer is located on the side of the lithium metal battery separator close to the negative electrode.

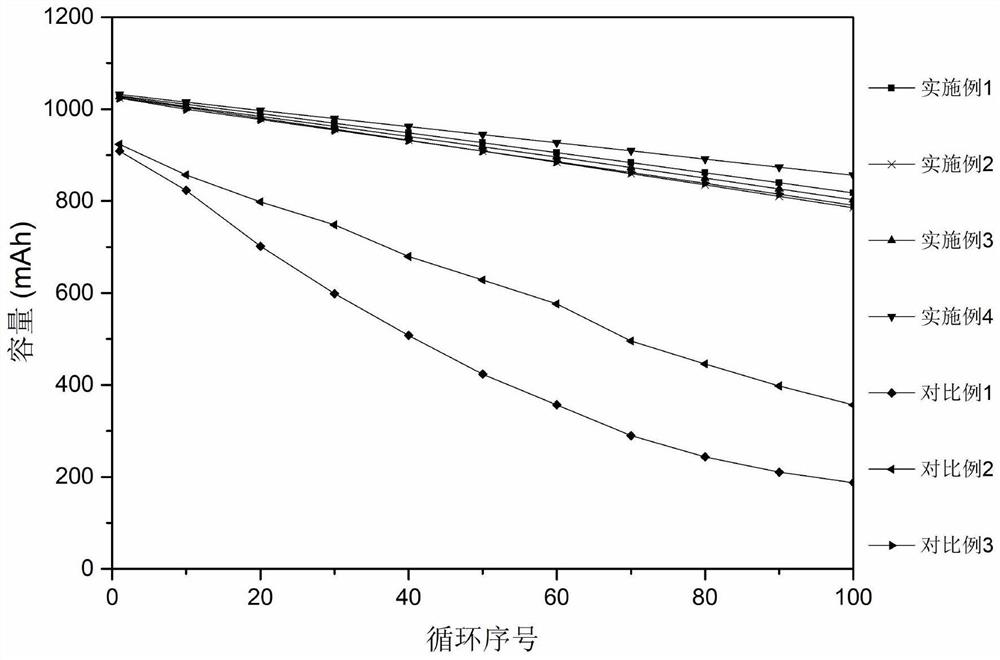

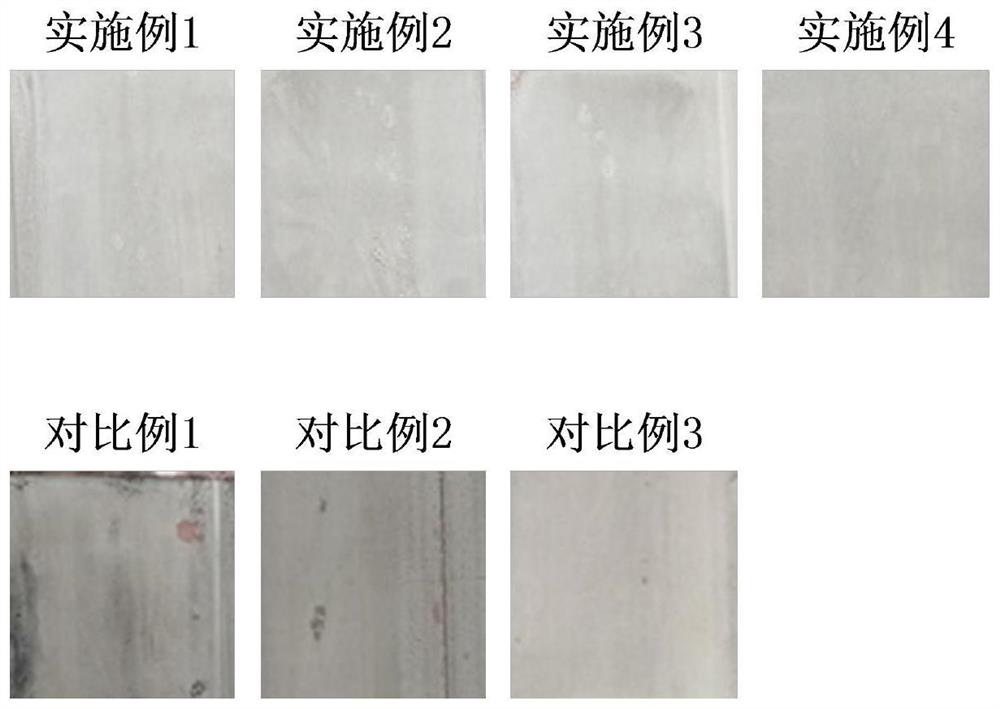

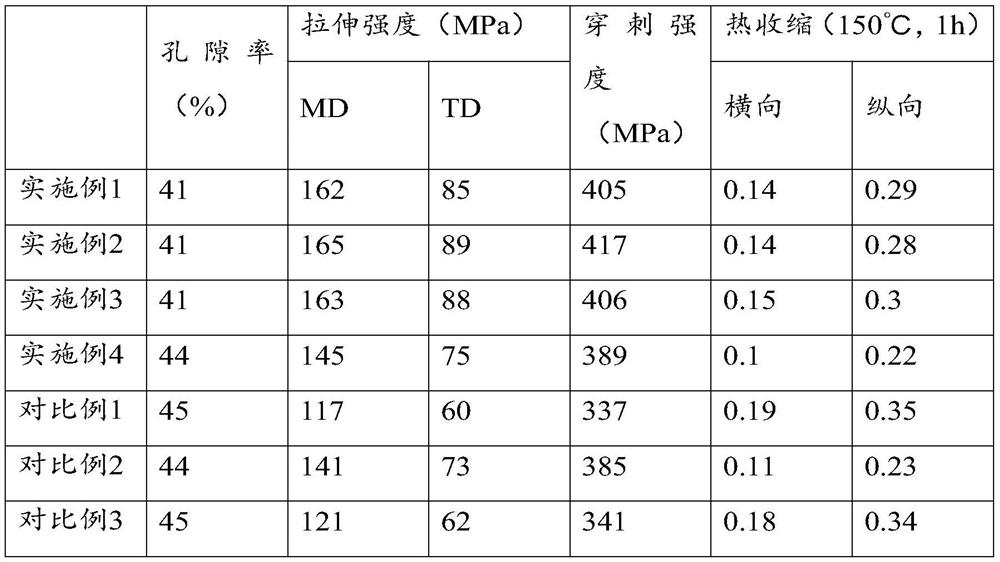

Embodiment 1

[0042] (1) Preparation of diaphragm

[0043] Step 1: Mix the ultra-high molecular weight polypropylene powder and the fluororubber 26 powder in a mass ratio of 20:1 to make a mixed powder;

[0044] Step 2: using a wet process known to those skilled in the art to prepare a modified polymer diaphragm filled with reinforcing materials, and the thickness of the diaphragm is 12 μm;

[0045] Step 3: A nano-magnesium layer is deposited on one side of the separator prepared in step 2 by the method of magnetron sputtering, and the thickness of the nano-magnesium layer is 3 μm, that is, the lithium metal battery separator is prepared.

[0046] (2) Battery production

[0047] The above-mentioned separator is used to assemble a lithium metal battery with a positive electrode, a negative electrode, an electrolyte and a casing. The manufacturing method thereof is known to those skilled in the art. One thing that needs special attention is that the lithiophilic material layer of the separat...

Embodiment 2

[0049] (1) Preparation of diaphragm

[0050] Step 1: Mix the ultra-high molecular weight polypropylene powder and the fluororubber 26 powder in a mass ratio of 20:1 to make a mixed powder;

[0051] Step 2: using a wet process known to those skilled in the art to prepare a modified polymer diaphragm filled with reinforcing materials, and the thickness of the diaphragm is 12 μm;

[0052] Step 3: depositing ZnO nanorods on one side of the separator prepared in step 2 by using the seed-mediated method, the thickness of the ZnO nanorod layer is 3 μm, and the lithium metal battery separator is prepared.

[0053] (2) Battery production

[0054] A battery was fabricated in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com