Manufacturing process of new energy battery box based on extruded profile

A technology of extruded profile and manufacturing process, which is applied in the field of new energy auto parts processing, can solve problems such as high cost and complex structure, and achieve the effects of good load-bearing capacity, good heat exchange effect, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

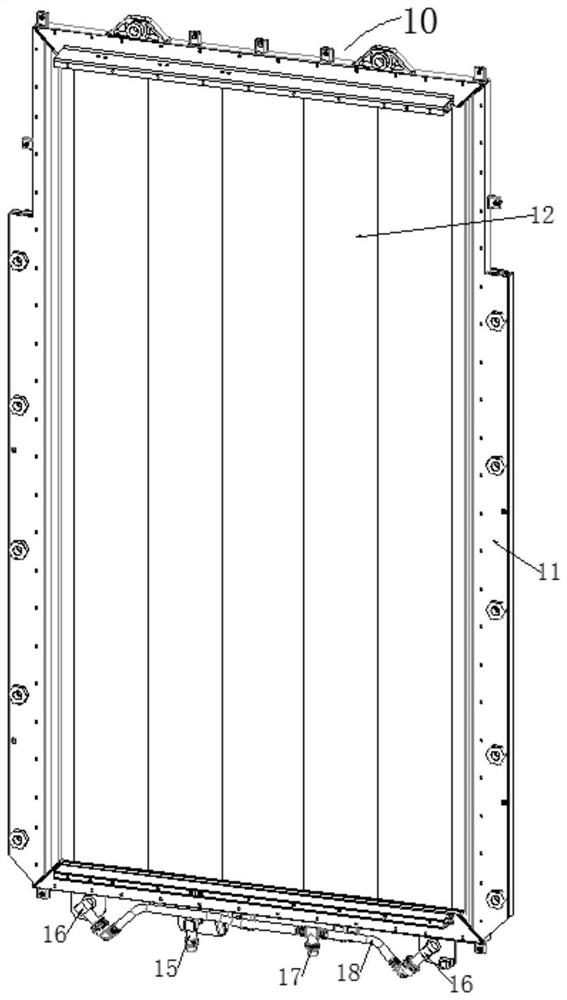

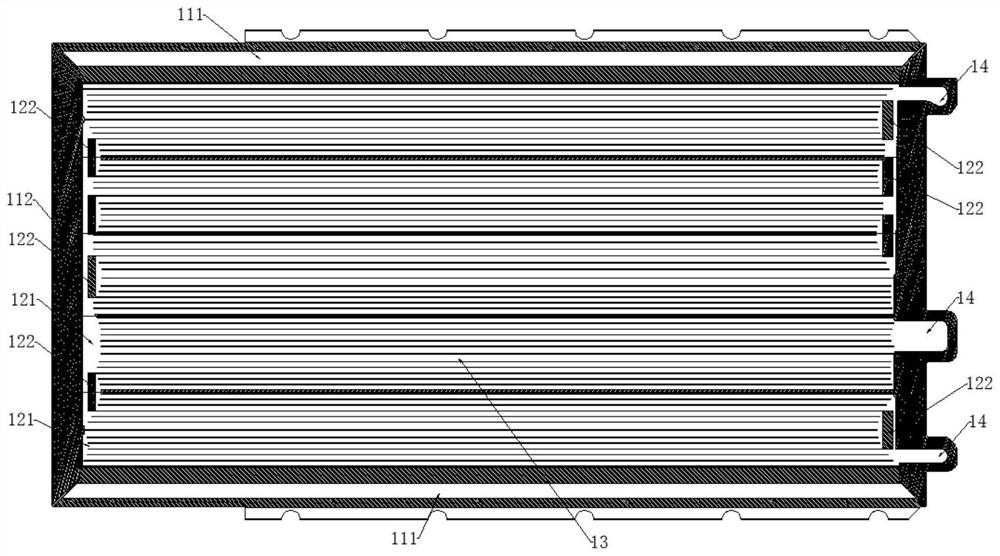

[0057] The specific embodiments and working principles of the present invention will be further described in detail below with reference to the accompanying drawings.

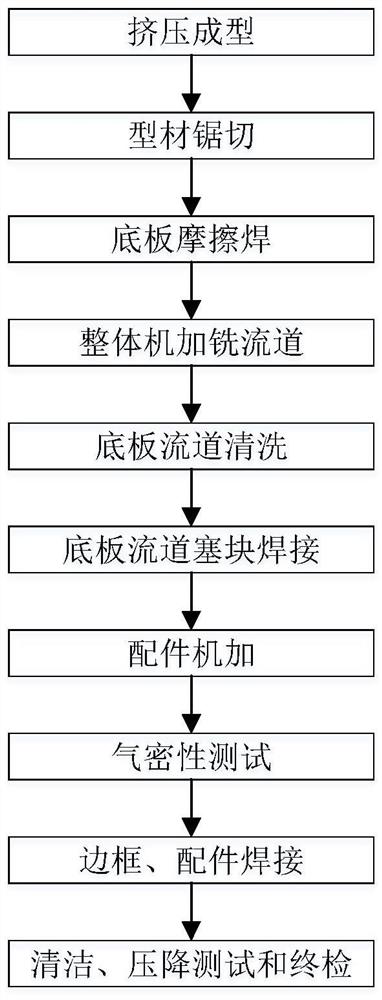

[0058] like figure 1 As shown, a manufacturing process of a new energy battery box based on extruded profiles includes the following steps:

[0059] Step 1: Extrude the required profile and inspect it. The inspection requires that the profile has no cracks, bubbles, deformation, twisting, no obvious scratches on the surface, no oxidation and other defects, and also requires materials, mechanical properties, dimensions, and harmful substances. And the salt spray test is up to the standard;

[0060] Step 2: Use a sawing machine to saw the profile, and clean it after sawing;

[0061] Use 5% degreaser for cleaning; meet pH 2.0 to 2.5; add degreaser and water to the cleaning pool once a day, and test; every two months, completely replace the pool water;

[0062] the cleaning method:

[0063] 1. First wash the inco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com