Construction method for large-diameter pile foundation of deep sand layer in karst development area

A construction method and large-diameter technology, applied in infrastructure engineering, drilling equipment and methods, excavation, etc., can solve the problems of poor construction efficiency, high safety risk, slow construction progress, etc., to achieve high construction efficiency and avoid corresponding costs. , to avoid the effect of orifice collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

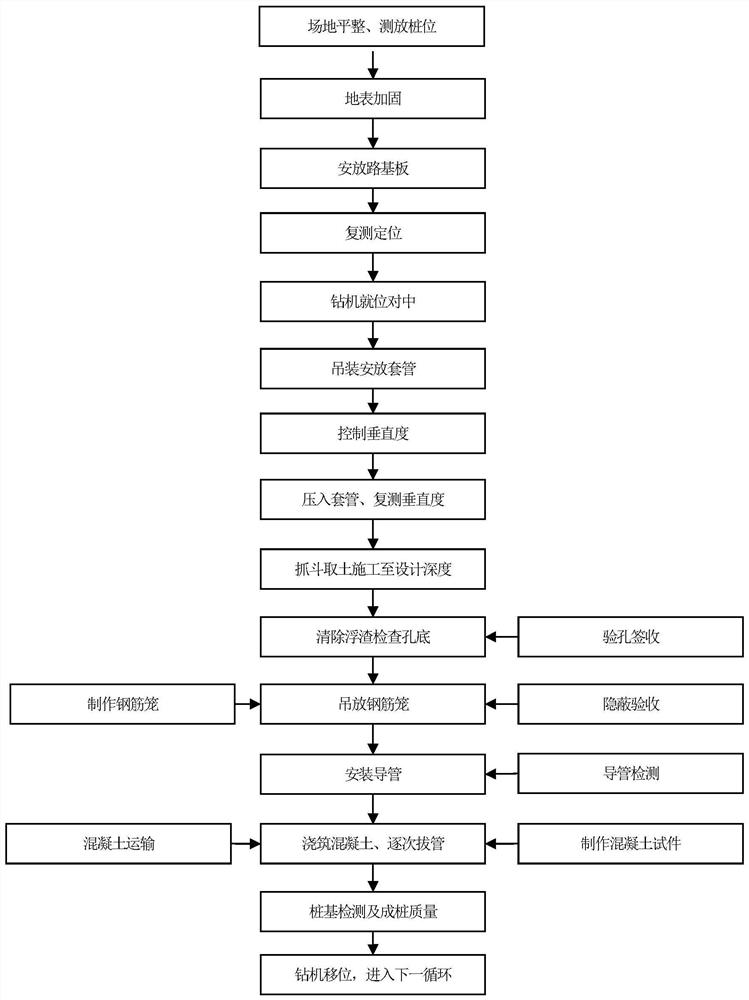

[0042] The invention discloses a construction method for a large-diameter pile foundation in a deep sand layer in a karst developed area. figure 1 As shown in the figure, the construction method has been applied in the deep sand layer, karst development and adjacent existing line sections of Guangzhou Baiyun Station No. 1, and the technology has been summarized.

[0043]Guangzhou Baiyun Station No. 1 is located in Baiyun District, Guangzhou City, Guangdong Province. The starting and ending mileage of the Liuxi River Bridge is GXLDK11+537.91~GXLDK13+237.035, with a length of 1.699 kilometers, of which the 49#-55# piers have relatively developed geological karsts. By using the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com