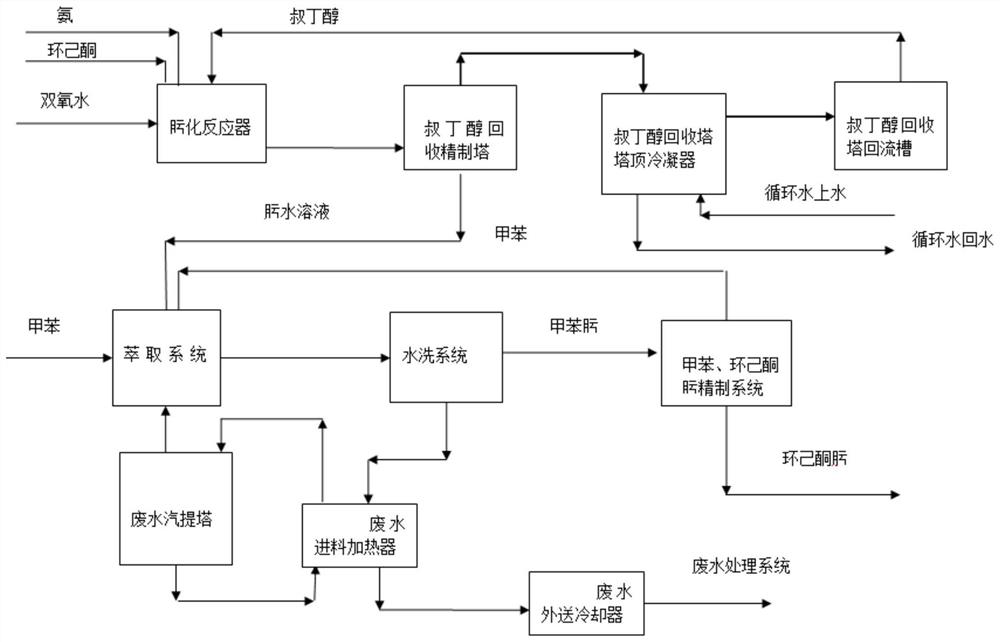

Cyclohexanone ammoximation production system and method

A technology of cyclohexanone amidoxime and production system, which is applied in the field of caprolactam oximation, can solve the problems of unutilized heat energy of gas phase at the top of the tower, increase the cost of wastewater treatment, increase the discharge amount of wastewater, etc., so as to reduce the amount of wastewater generated and increase the load. The effect of adjusting the range and reducing the discharge amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

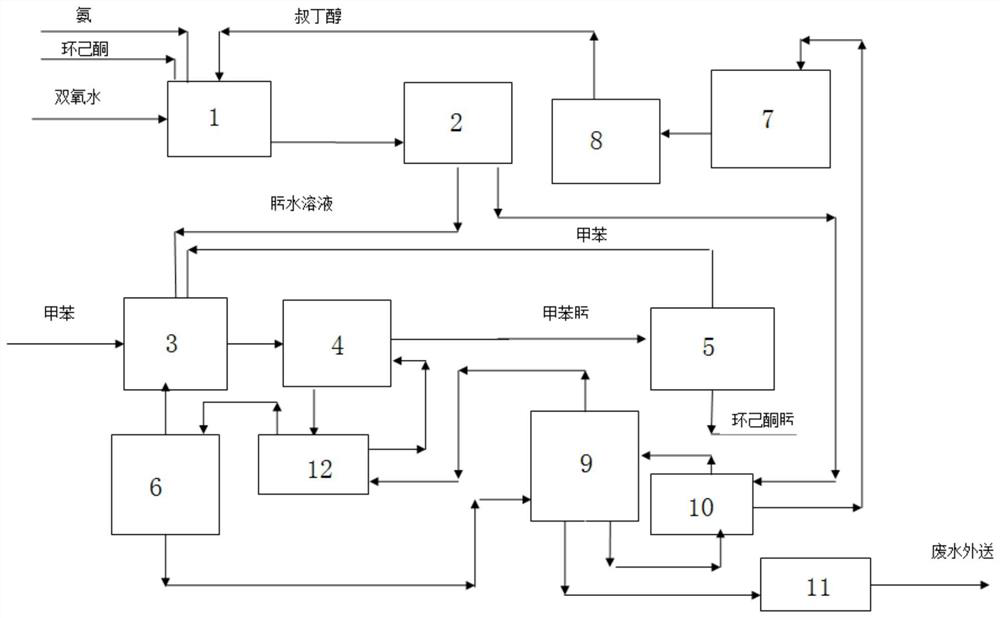

[0030] The present embodiment provides a cyclohexanone ammoximation production system, such as figure 2 As shown, an oximation reactor 1 is included, and the oximation reactor 1 can use tert-butanol as a solvent to react the introduced hydrogen peroxide, cyclohexanone and gaseous ammonia to produce cyclohexanone oxime.

[0031] The oximation reactor 1 is connected with the tert-butanol recovery and purification column 2, and the reaction product of the oximation reactor 1 can be sent to the tert-butanol recovery and purification column 2, and the tert-butanol recovery and purification column 2 separates the reaction product, and the tert-butanol is recovered and purified. The column bottom liquid phase pipe of the alcohol recovery and purification tower 2 is connected to the extraction system 3, and the separated oxime aqueous solution, that is, the cyclohexanone oxime solution, can be discharged into the extraction system 3, and the extraction system 3 can adopt the existing ...

Embodiment 2

[0045] The present embodiment discloses a working method of the cyclohexanone ammoximation production system described in Embodiment 1:

[0046] In the oximation reactor 1, hydrogen peroxide, cyclohexanone and ammonia gas are added according to the set ratio, and tert-butanol is added as a solvent, and the reaction occurs in the oximation reactor 1 to produce cyclohexanone oxime, and the oximation reactor The reaction product is discharged into the tert-butanol recovery and purification tower 2, the tert-butanol recovery and purification tower 2 works, and the oxime aqueous solution generated during operation is discharged into the extraction system 3 by using the liquid phase pipe of the tower body, and the extraction system 3 adds toluene to the discharge. The extracted oxime aqueous solution is extracted, and the process water in the oxime aqueous solution is removed. The extracted toluene and cyclohexanone oxime mixture enters the water washing system 4 for washing, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com