High-activity molybdenum compound loaded boron fuel and ion exchange method preparation method

A technology of ion exchange method and molybdenum compound, which is applied in the field of preparation of boron fuel, boron fuel loaded with molybdenum compound and ion exchange method, to achieve the effects of accurate and controllable content, shortened laser ignition delay time, and safe preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

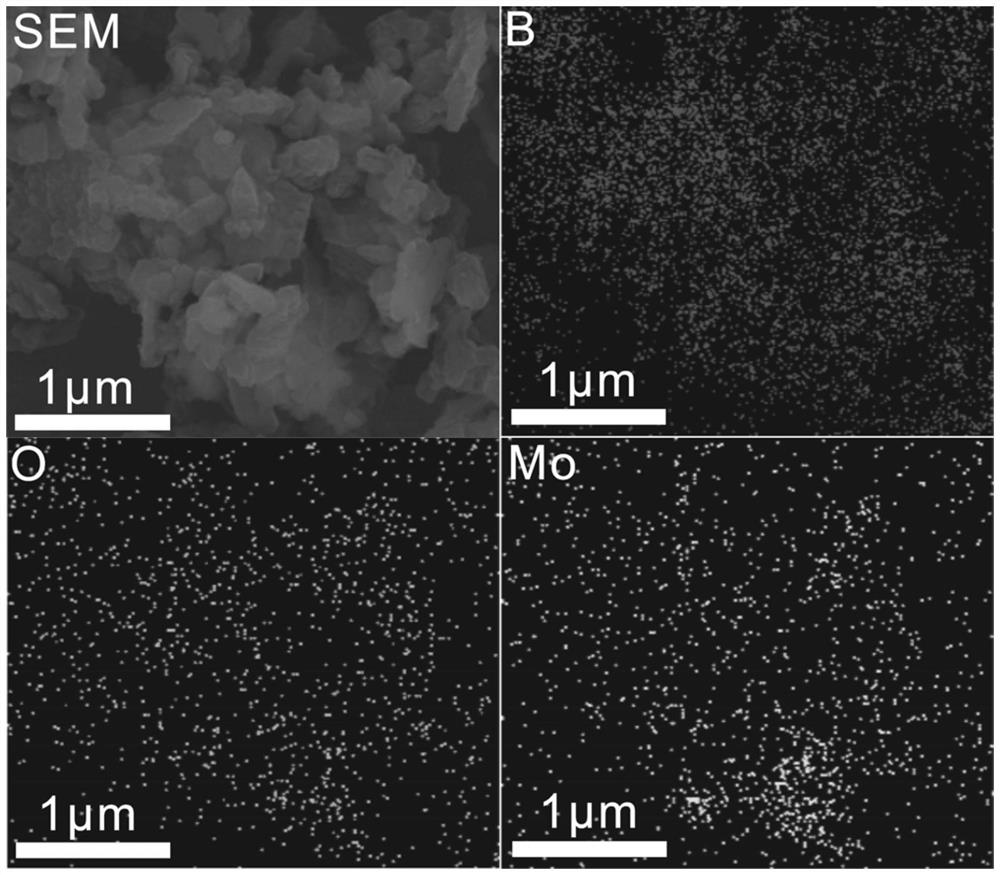

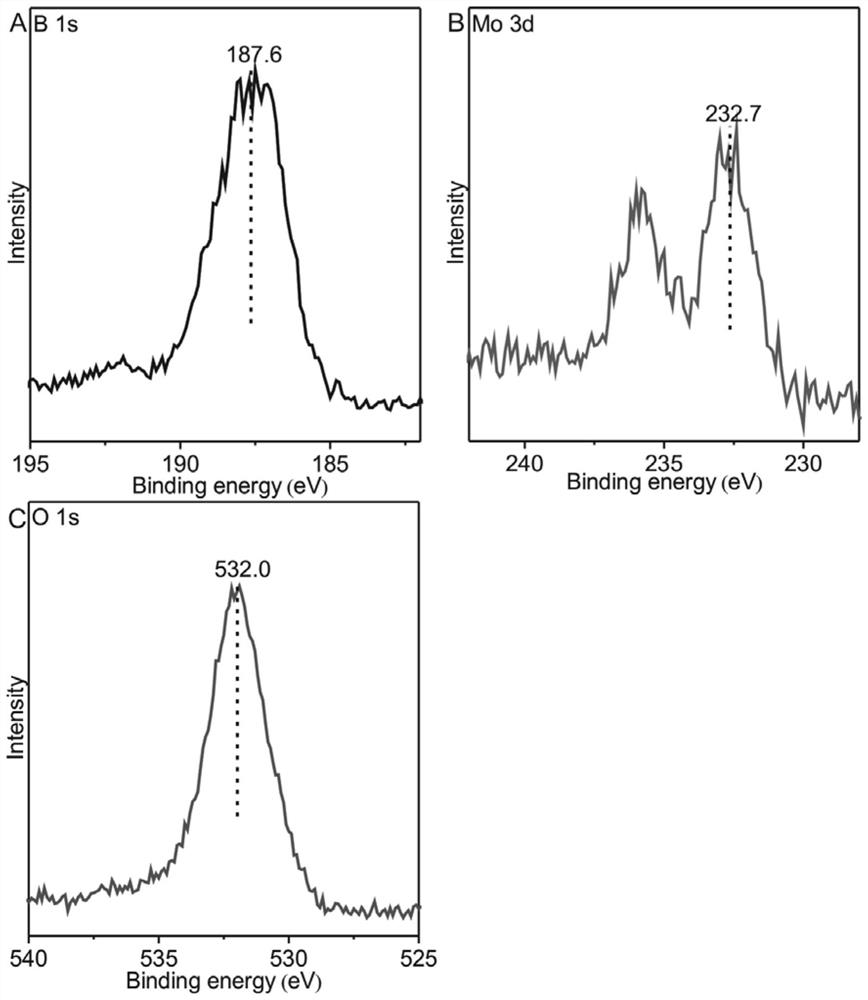

[0049] The present embodiment provides a method for preparing a molybdenum compound-loaded boron fuel by an ion-exchange method. The method adopts an ion-exchange method to load molybdenum compound particles or films on the surface of boron powder to form a molybdenum compound-loaded boron fuel;

[0050] The ion exchange method uses molybdenum salt as the molybdenum source, and after ion exchange with the species on the surface of the boron powder, the exchange intermediate product is obtained, and the exchange intermediate product is heated at high temperature to obtain the boron fuel loaded with the molybdenum compound.

[0051] In this embodiment, the molybdenum salt is ammonium molybdate ((NH 4 ) 6 Mo 7 O 24 ).

[0052] In this embodiment, the method specifically includes the following steps:

[0053] Step 1: Weigh 1g of boron powder into a conical flask, add 60ml of deionized water, sonicate for 10min and continue stirring to completely suspend the boron powder in the...

Embodiment 2

[0060] The present embodiment provides a method for preparing a molybdenum compound-loaded boron fuel by an ion-exchange method. The method adopts an ion-exchange method to load molybdenum compound particles or films on the surface of boron powder to form a molybdenum compound-loaded boron fuel;

[0061] The ion exchange method uses molybdenum salt as the molybdenum source, and after ion exchange with the species on the surface of the boron powder, the exchange intermediate product is obtained, and the exchange intermediate product is heated at high temperature to obtain the boron fuel loaded with the molybdenum compound.

[0062] In the present embodiment, the molybdenum salt is sodium molybdate (Na 2 MoO 4 ).

[0063] In this embodiment, the method specifically includes the following steps:

[0064] Step 1: Weigh 1g of boron powder into a conical flask, add 60ml of deionized water, sonicate for 10min and continue stirring to completely suspend the boron powder in the water...

Embodiment 3

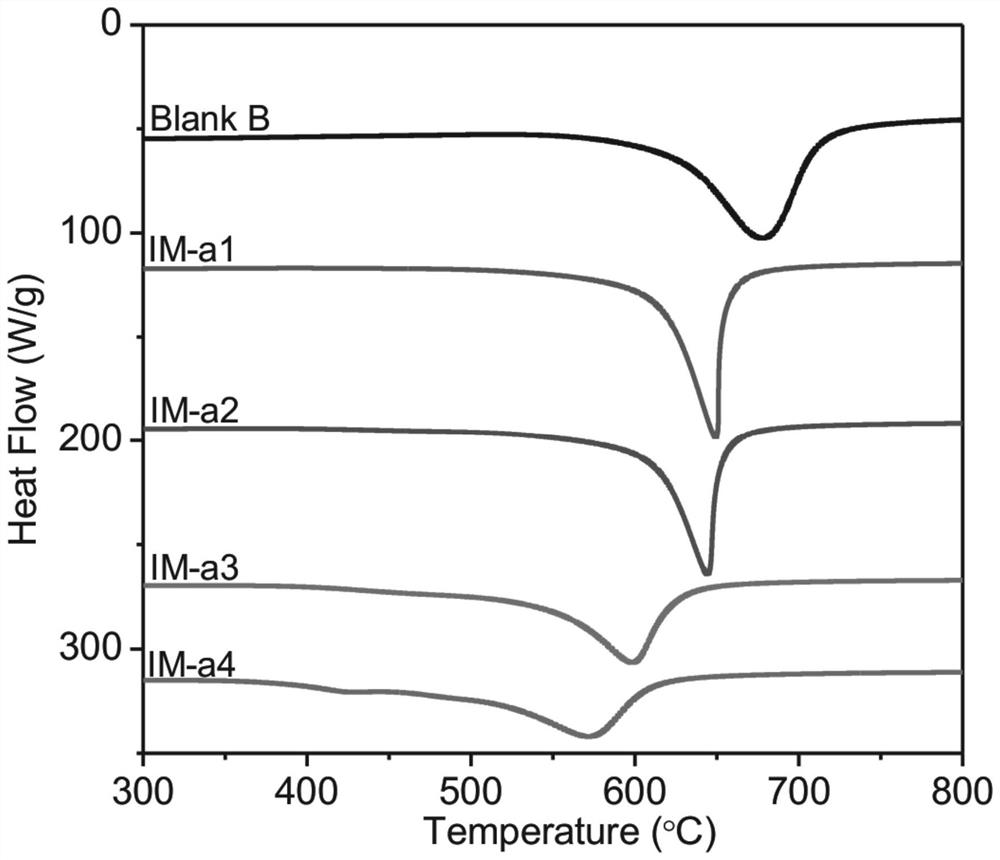

[0073] This example provides the TG-DSC test of the boron fuel loaded with molybdenum compound, and the TG-DSC test method is: weigh an appropriate amount of MoO x / B High active boron powder fuel is placed in the sample stage of the TG-DSC instrument, the heating rate of the instrument is set to 10°C / min, the test temperature range is 50-1000°C, and the test atmosphere is air atmosphere, so that the loaded molybdenum can be obtained. TG and DSC curves of compound boron fuel.

[0074] Specifically, weigh an appropriate amount of molybdenum compound-loaded boron fuel and place it in the sample stage of the TG-DSC instrument, set the heating rate of the instrument to be 10°C / min, the test temperature range to be 50-1000°C, and the test atmosphere to be an air atmosphere. In this way, the TG and DSC curves of the molybdenum compound-loaded boron fuel can be obtained.

[0075] Table 1 shows the TG-DSC data of the molybdenum compound-loaded boron fuel of the present invention.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com