Superfine powder preparing method

A technology of ultrafine powder and filaments, applied in the field of ultrafine powder preparation, can solve the problems of large average particle size of nanoparticles, wide range of particle size distribution, low yield of nanoparticles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

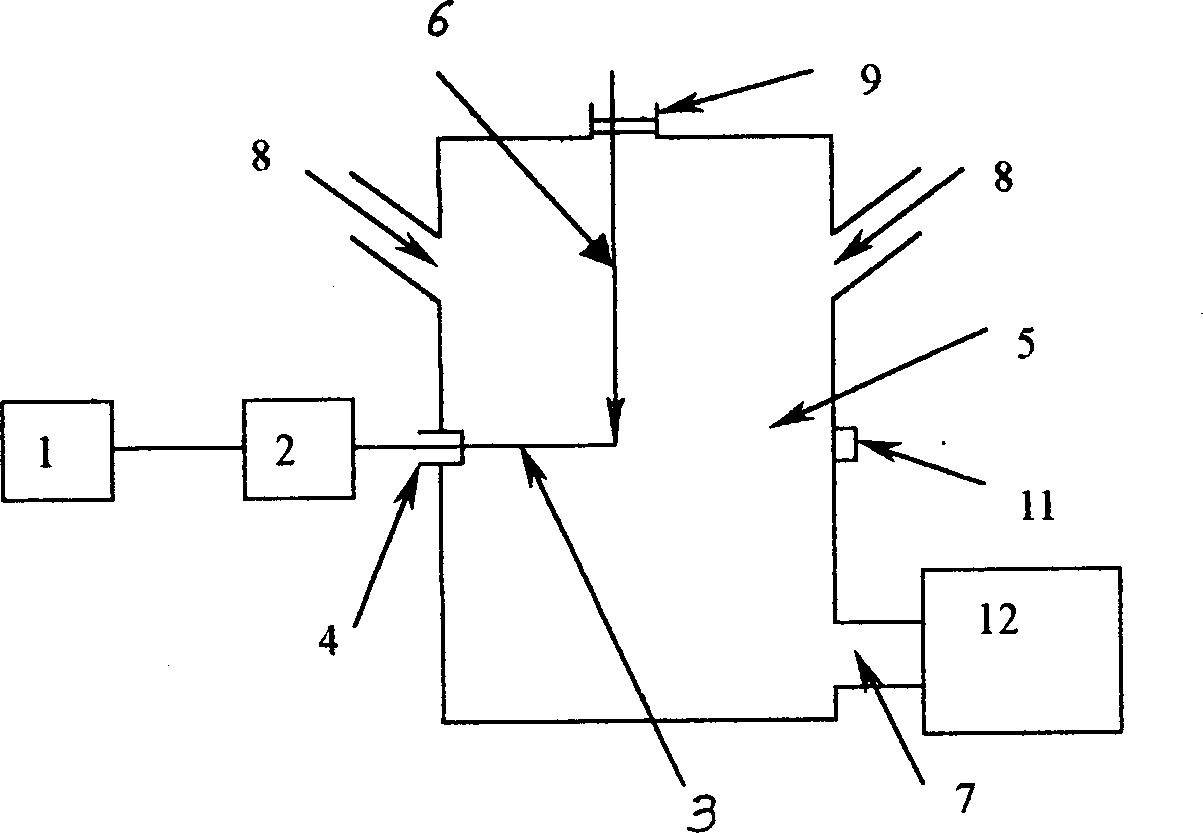

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Prepare nano-aluminum powder by ablation of Al filament target with laser beam

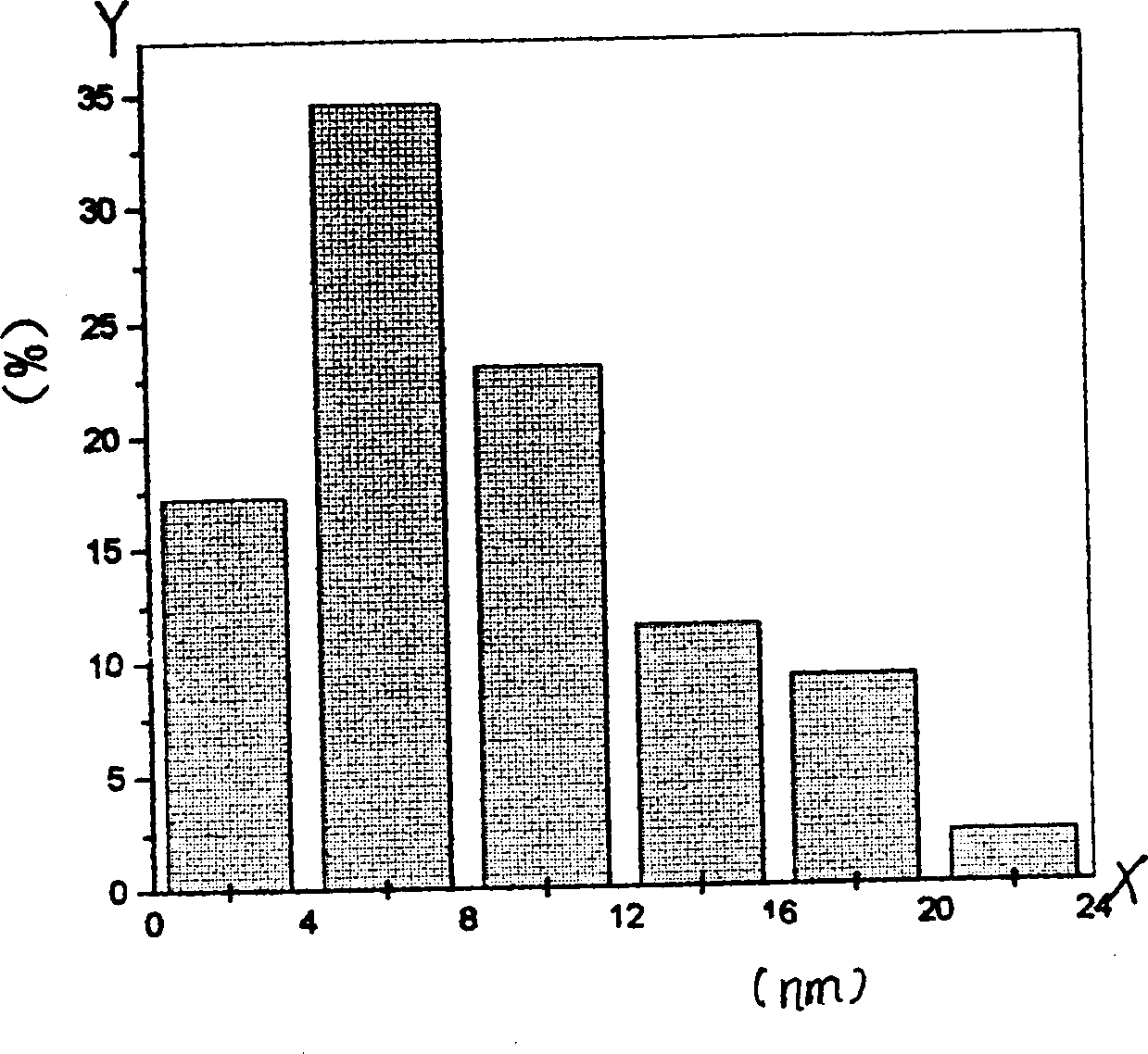

[0015] The YAG laser is selected, the pulse laser energy used is 15J / pulse, the average output power is 300W, the pulse repetition frequency is 20Hz, the pulse width is 1.3ms, and the spot diameter is 0.5mm. At this time, the corresponding laser energy density is 7.6×10 3 J / cm 2 , with a power density of 5.9×10 6 W / cm 2. Argon gas was introduced into the reaction chamber, and the vacuum degree was maintained at 500Pa. The diameter of the aluminum wire used is 0.5mm, and the experiment shows that the yield of nano-aluminum powder under this condition (average power 300W) is about 25 grams / hour. If the other parameters are kept constant and the average laser power is increased to 1 kW, the production rate of powder can reach 83 g / h. figure 2 Shown is the particle size distribution histogram of the ultrafine powder, in which the x-axis represents the diameter of the ultrafine...

Embodiment 2

[0016] Embodiment 2: Preparation of nano silver powder by laser ablation silver wire

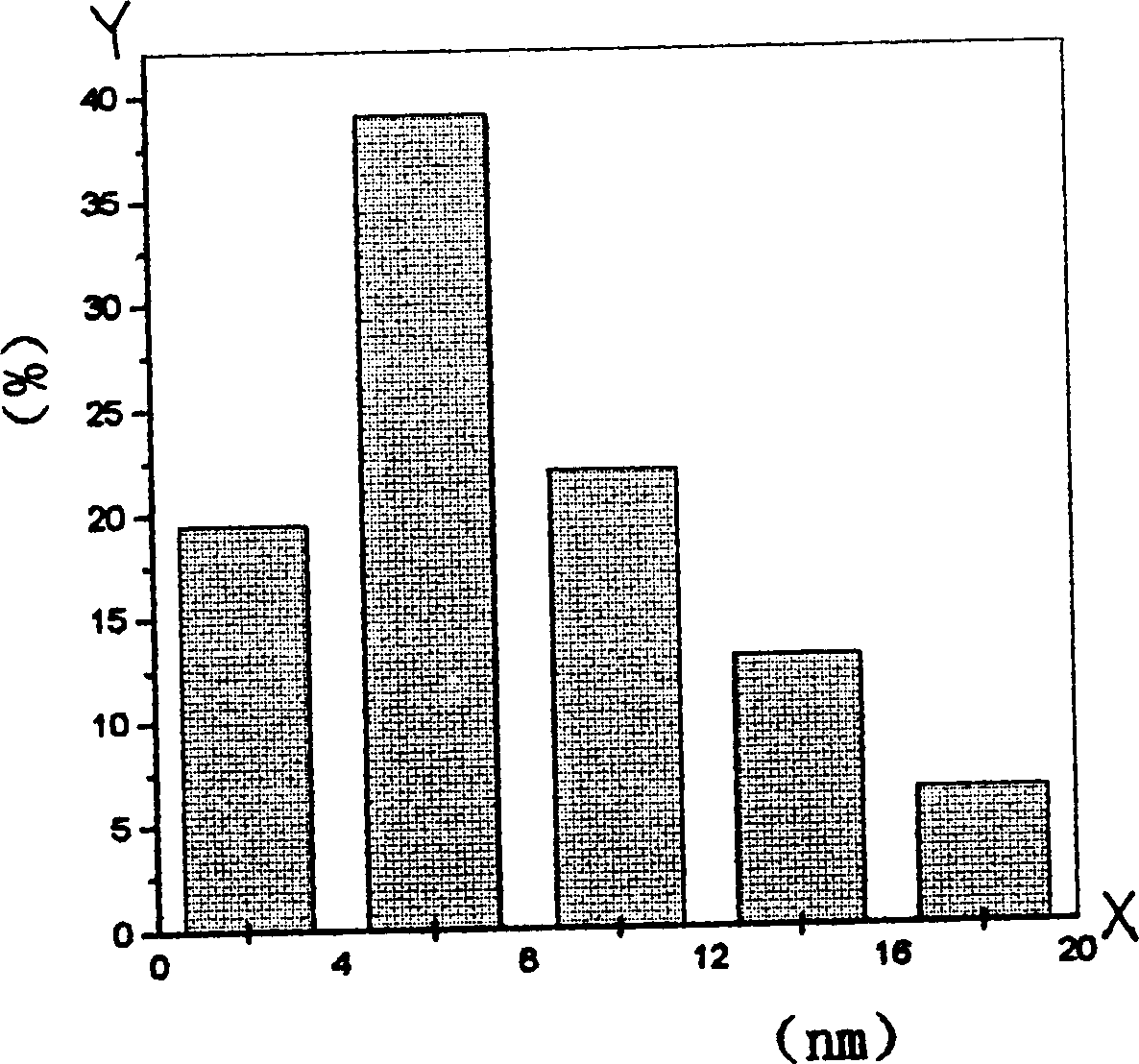

[0017] The YAG laser is selected, the pulse laser energy used is 30J / pulse, the average output power is 300W, the pulse repetition frequency is 10Hz, the pulse width is 0.5ms, and the spot diameter is 0.5mm. At this time, the corresponding laser energy density is 1.5×10 4 J / cm 2 , with a power density of 3.0×10 7 W / cm 2 . In the experiment, argon gas was introduced into the reaction chamber, and the vacuum degree was maintained at 1000 Pa, and the diameter of the silver wire used was 0.5 mm. Experiments show that the production rate of the nano-silver powder under this condition (average power 300W) is 94.5 grams / hour. If other parameters are kept constant and the average laser power is increased to 1 kW, the production rate of powder can reach 315 g / h. image 3 A histogram of the particle size distribution of the silver superfine powder is shown, in which the x-axis represents the dia...

Embodiment 3

[0018] Embodiment 3: Preparation of nanopowder by laser ablation of graphite

[0019] The YAG laser is selected, the pulse laser energy used is 30J / pulse, the average output power is 300W, the pulse repetition frequency is 10Hz, the pulse width is 0.3ms, and the spot diameter is 0.5mm. At this time, the corresponding laser energy density is 3.8×10 3 J / cm 2 , with a power density of 1.27×10 7 W / cm 2 . The reaction chamber was vented with argon, and the vacuum degree was maintained at 1000Pa. The diameter of the carbon filament used in the experiment is 0.5mm. Experiments show that the production rate of the nano-graphite powder under this condition (average power 300W) is 24.7 grams / hour. If the other parameters remain unchanged and the average laser power is increased to 1 kW, the production rate of ultrafine powder can reach 82.3 g / h. Moreover, the average particle diameter of the ultrafine powder is lower than 6nm, and the particle size distribution range is 1-15nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com