Bolt loss defect detection method, system and device

A defect detection and bolt technology, applied in image analysis, image enhancement, instruments, etc., can solve problems such as the inability to fully express the defect state and affect the detection accuracy of the model, achieve accurate automatic machine vision judgment, solve low detection accuracy, and avoid Lu Weak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

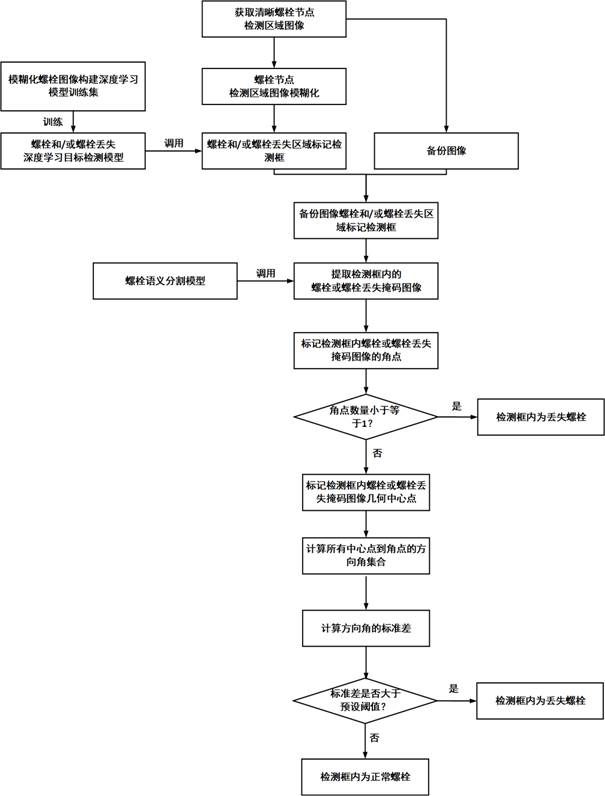

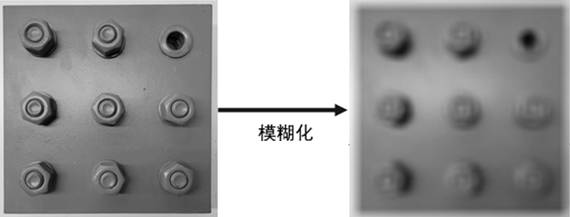

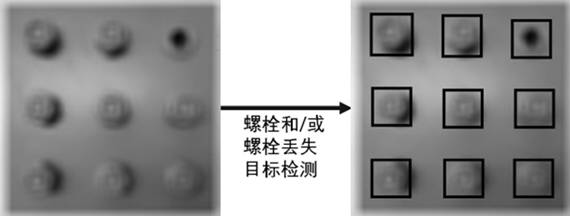

Method used

Image

Examples

Embodiment approach

[0157] In yet another implementation manner, this solution may be implemented by means of a device, and the device may include corresponding modules for performing each or several steps in the above-mentioned various implementation manners. A module may be one or more hardware modules specifically configured to perform the corresponding step, or implemented by a processor configured to perform the corresponding step, or stored within a computer-readable medium for implementation by the processor, or via some combination to achieve.

[0158] The processor performs the various methods and processes described above. For example, the method embodiments in the present scheme may be implemented as a software program tangibly embodied on a machine-readable medium, such as a memory. In some embodiments, some or all of the software program may be loaded and / or installed via memory and / or a communication interface. One or more steps of the methods described above may be performed when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com