Subway tunnel air-bag type soft blowing pipe

A technology of tunnel air and air supply pipes, which is applied in the direction of hoses, pipes, and pipeline layouts. It can solve the problems of increasing the volume and weight of hoses, and the inconvenience of transporting and placing air supply pipes, so as to maintain smooth air volume and low cost. , making easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

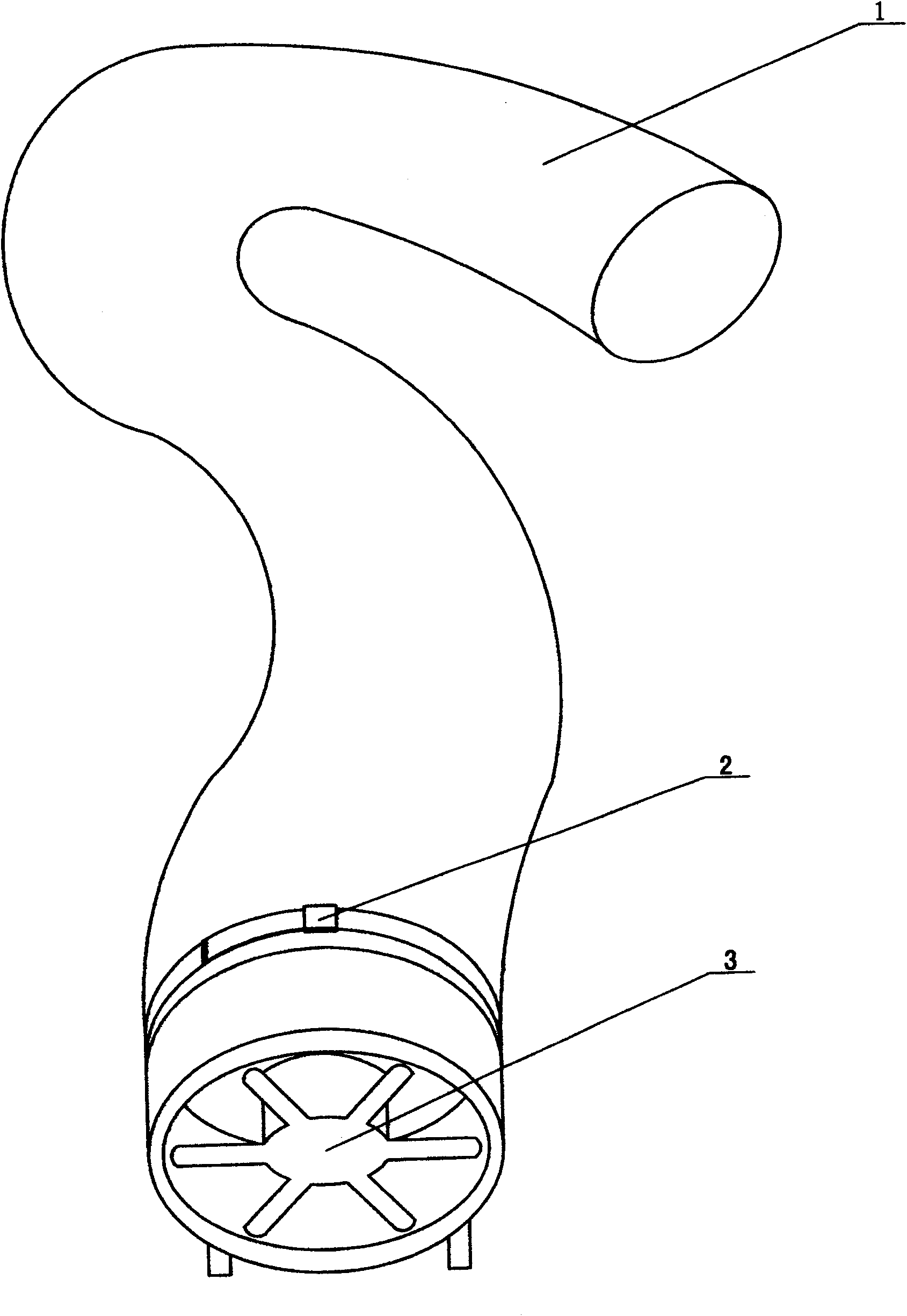

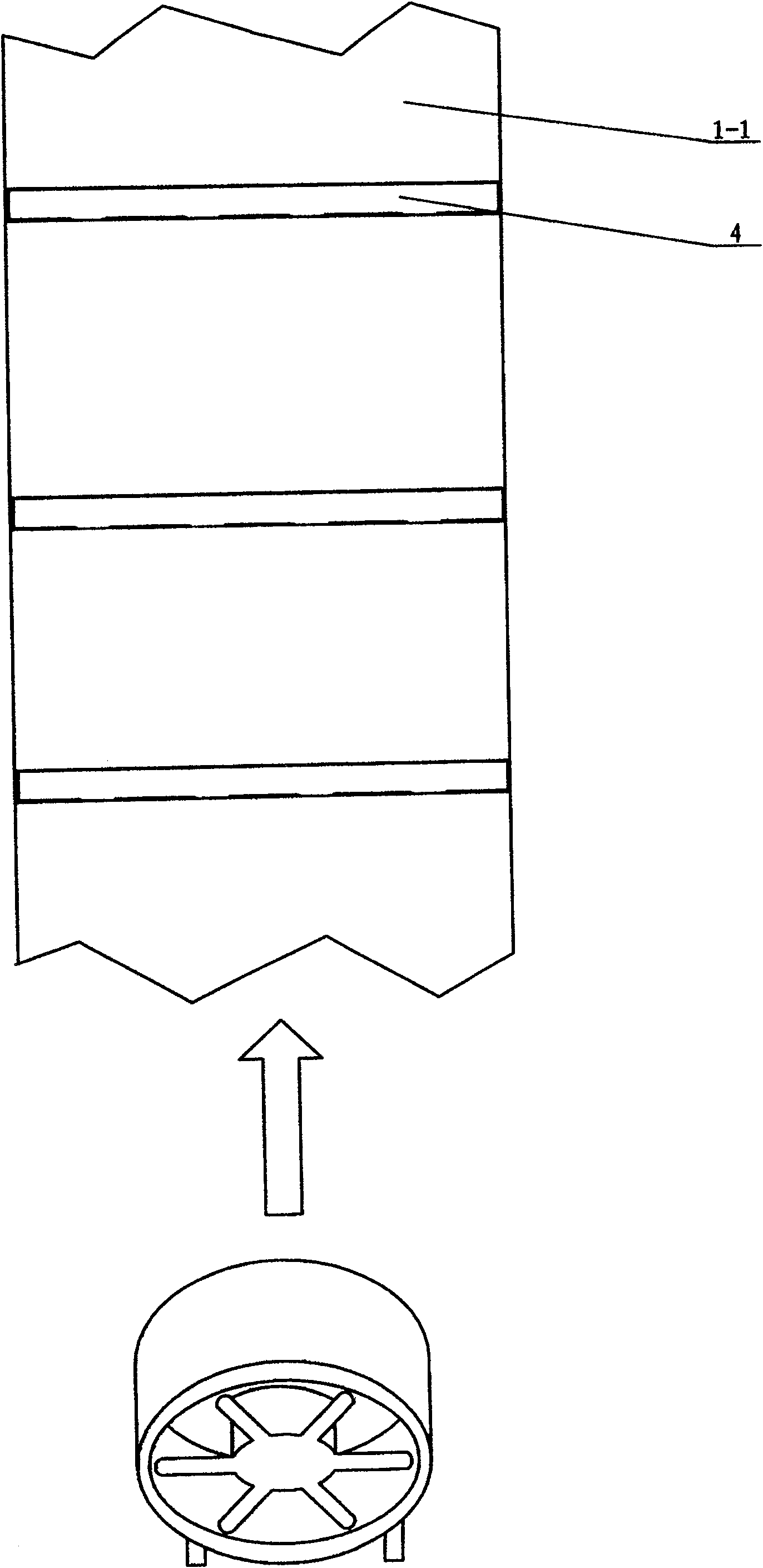

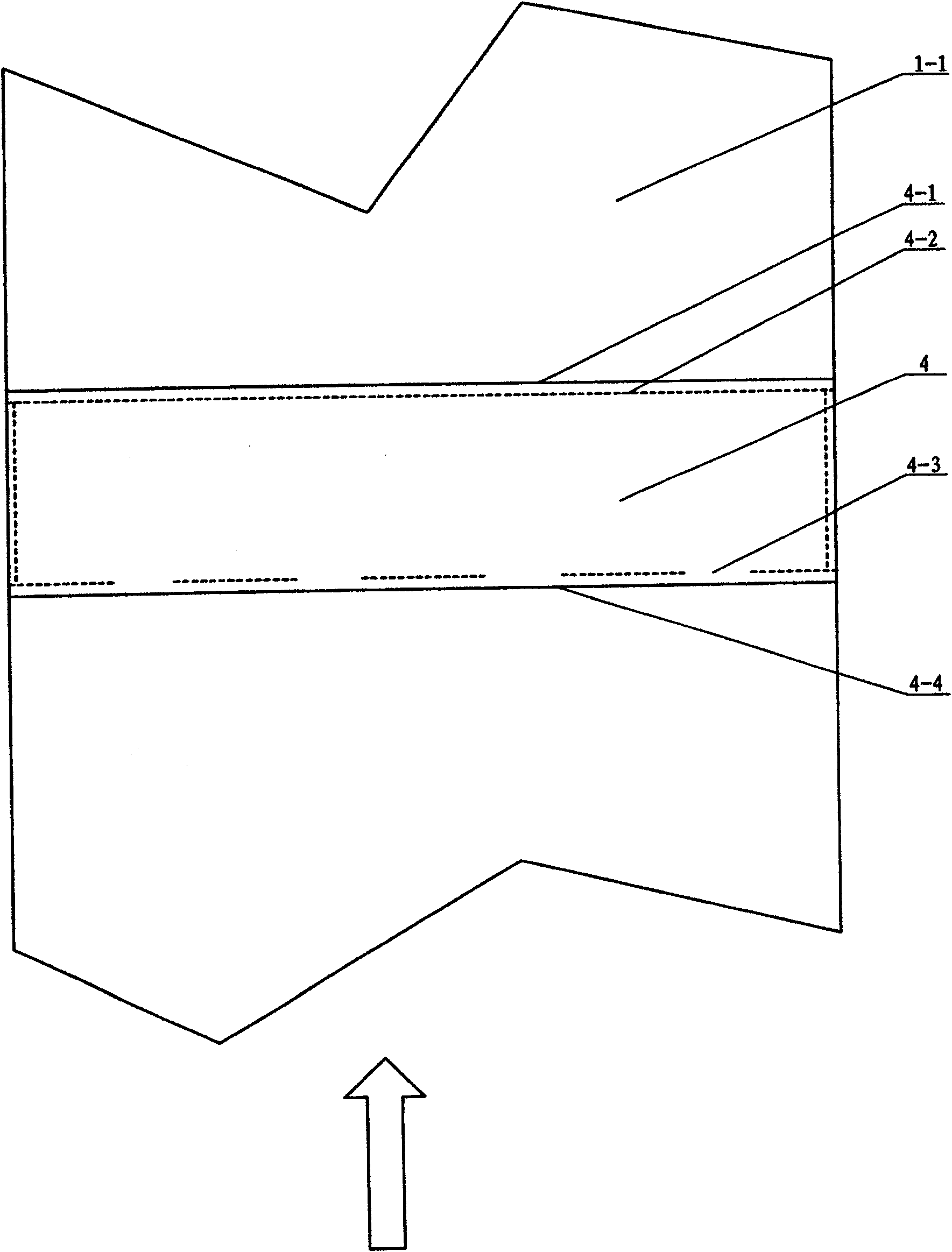

[0021] Embodiment 1 from figure 1 , figure 2 and image 3 Find out in, the software air supply pipe that the present invention introduces, the air supply pipe is made up of air pipe 1, air pipe tight buckle 2, air blower 3, wind pocket 4. On the air duct inner wall 1-1, a circle of wind pockets 4 is sewn at regular intervals (about 1.5 meters). The material used in the wind pockets 4 is the same as that of the air duct 1. Made of air-permeable fabric, the wind pocket cloth is cut into a long strip, and is directly sewn on the inner wall of the air duct 1-1 horizontally. When the wind pocket 4 is sewn, several wind pockets 4-3 are left, and the wind pocket is 4 points in front of the wind pocket. 4-4 and the wind pocket rear 4-1, the suture 4-2 near the wind pocket rear 4-1 is a whole seam, airtight; and the suture 4-2 near the wind pocket front 4-4 is left Wind pocket 4-3 place is not stitched, and wind is caught after blowing into wind pocket 4-3 from wind pocket, so it i...

Embodiment approach 2

[0027] Embodiment 2 Figure 10 It is the wind pocket 4 of another sewing method, and the wind pocket 4 is divided into small pockets by dividing sutures 4-5. Each small pocket is not connected to each other. A circle of the inner wall is made into several small pockets, correspondingly all have the air-ride opening 4-3, and the wind pocket 4 is filled with wind to make the air pipe 1 bulge, and the air supply pipe will not collapse. This method is that the wind pocket is relatively strong and can withstand a lot of wind.

Embodiment approach 3

[0028] Embodiment 3 Figure 11 It is the wind pocket 4 of another sewing method. There are dividing sutures 4-5 to divide the wind pocket 4 into small pockets, but the dividing sutures 4-5 are not sewn to the end, so there are left holes on both sides of the bottom of each small pocket. In this way, each small pocket is connected, and each small pocket has a wind pocket 4-3. This way, the wind pocket 4 will bulge better, and the separation stitches 4-5 strengthen the wind pocket 4. Strength, can withstand a lot of wind.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com