Industrial television brick

A TV brick and industrial technology, applied in the direction of TV, color TV, closed-circuit television system, etc., can solve the problems of glass substrate defects, glass substrate iron stones, etc., and achieve the effect of large viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

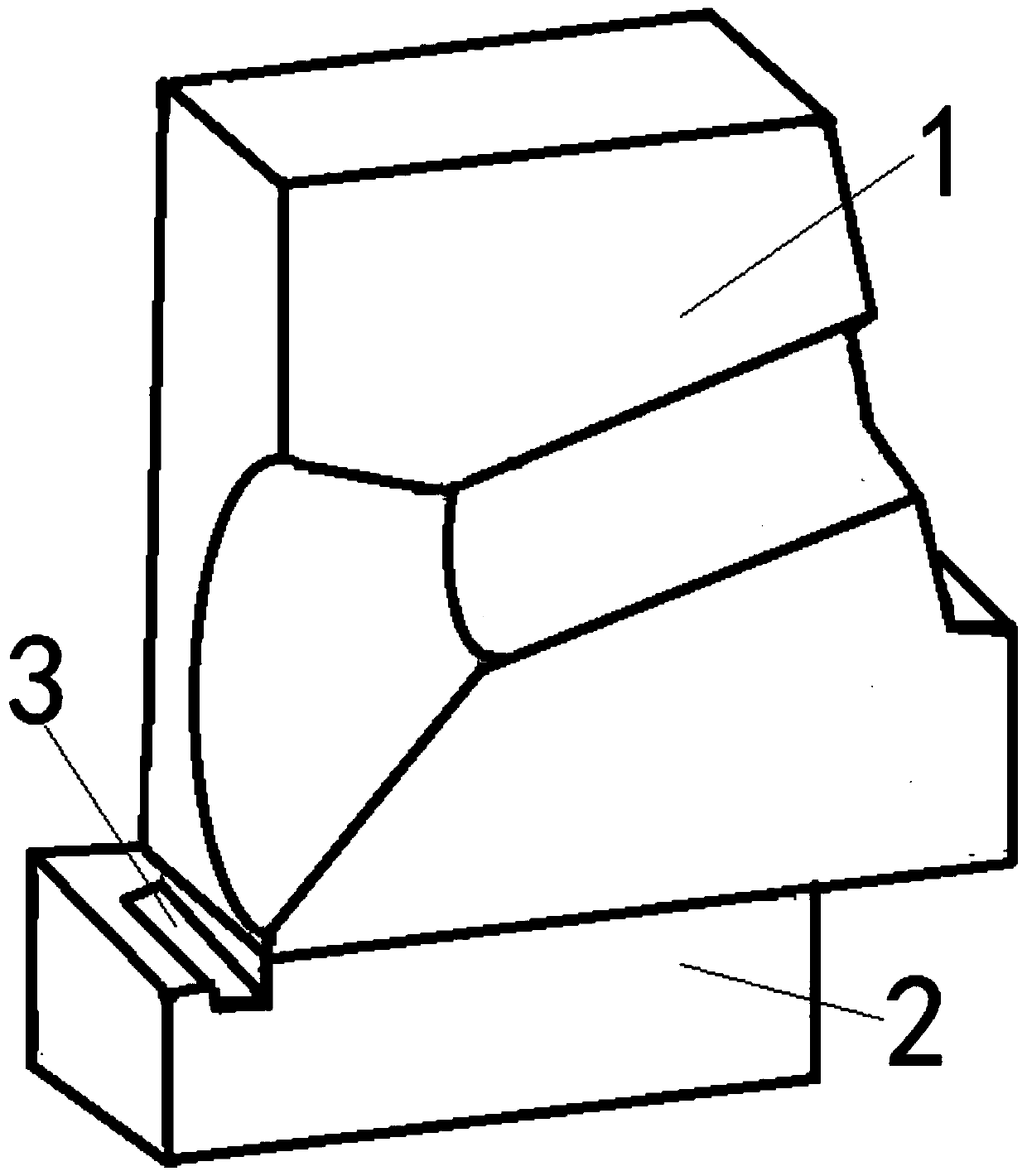

[0026] Such as figure 1 As shown, the industrial TV brick of the present invention includes a main body brick 1 and a pad brick 2 .

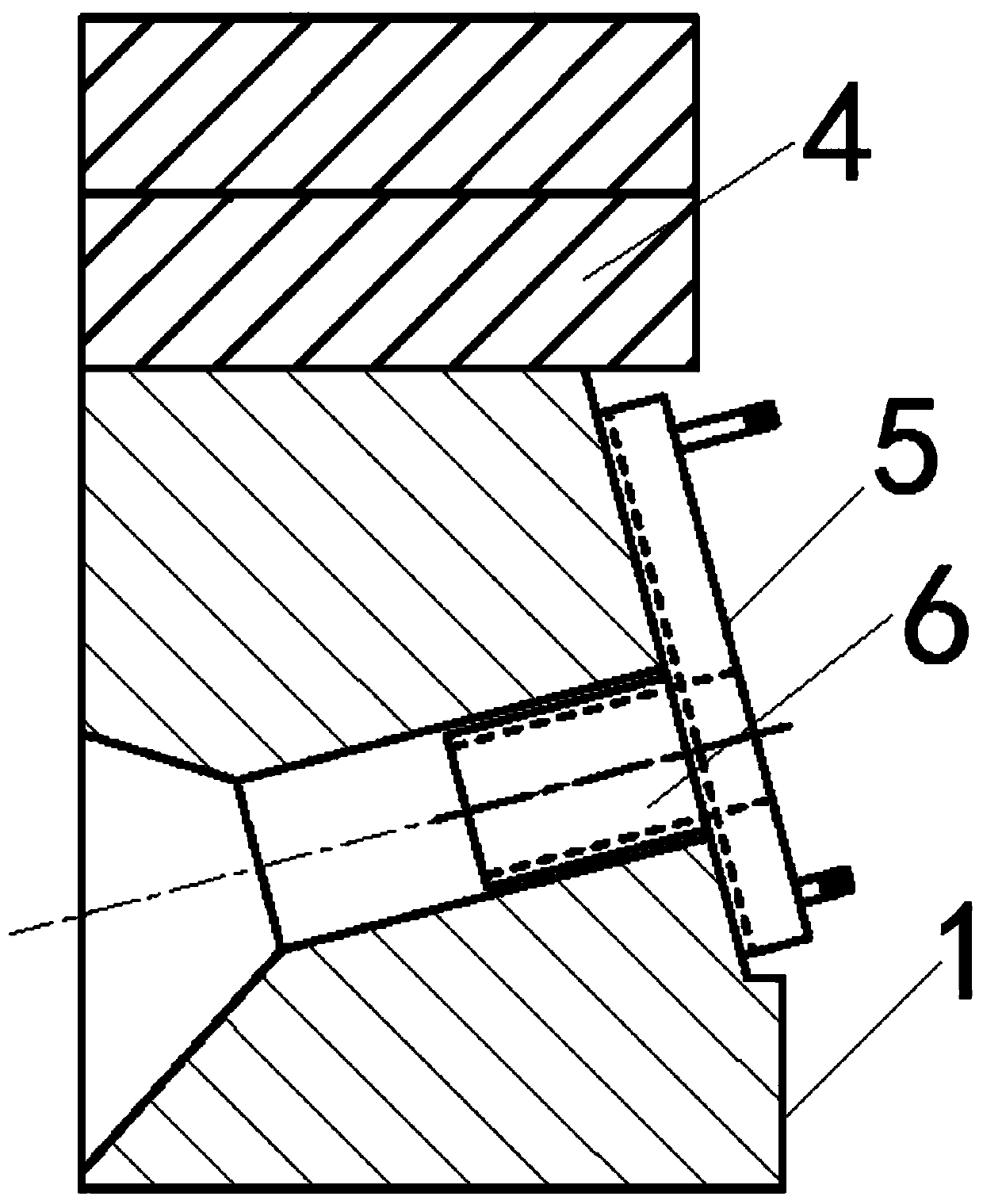

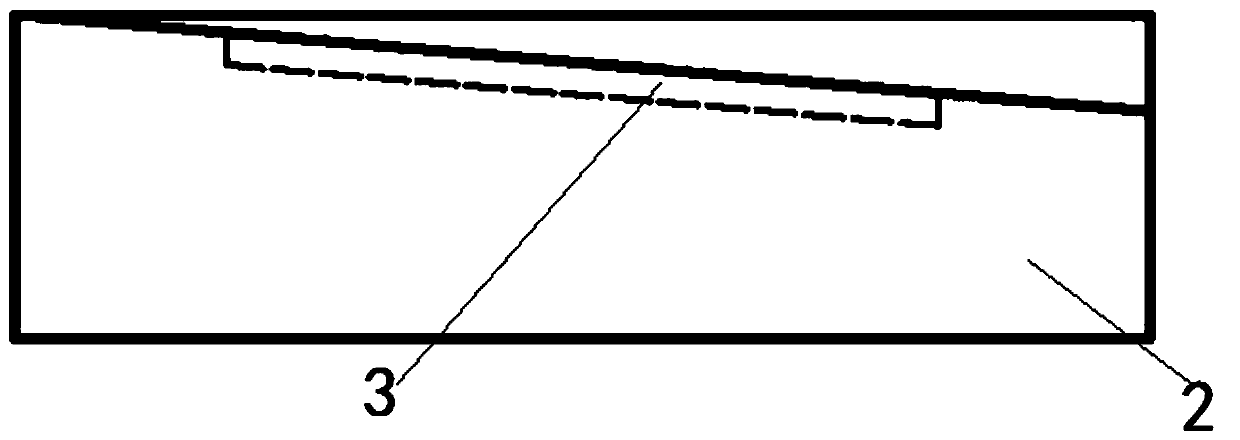

[0027] The body brick 1 is a cuboid structure, wherein the back is a slope, and the top of the back is inclined to the front; the body brick 1 is provided with a through hole, which connects the front and back of the body brick 1, and the through hole is perpendicular to the back slope of the body brick 1. The part of the through hole close to the back of the body brick 1 is a straight hole, the length of the straight hole is greater than the length of the industrial TV lens 6, and the diameter of the straight hole is not less than the diameter of the industrial TV lens 6; On the front surface of the body brick 1, the inclination angle of the opening of the bell mouth is 50°-85°, and the bell mouth can expand the shooting angle of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com