Preparation method and application of multichannel microfluidic electrochemical sensing chip

A sensor chip and multi-channel technology, which is applied in the field of nanomaterials and electrochemical sensing, can solve the problems of reducing sensor selectivity and sensitivity, and achieve enhanced electron transfer and material transport capabilities, low density, and adjustable pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

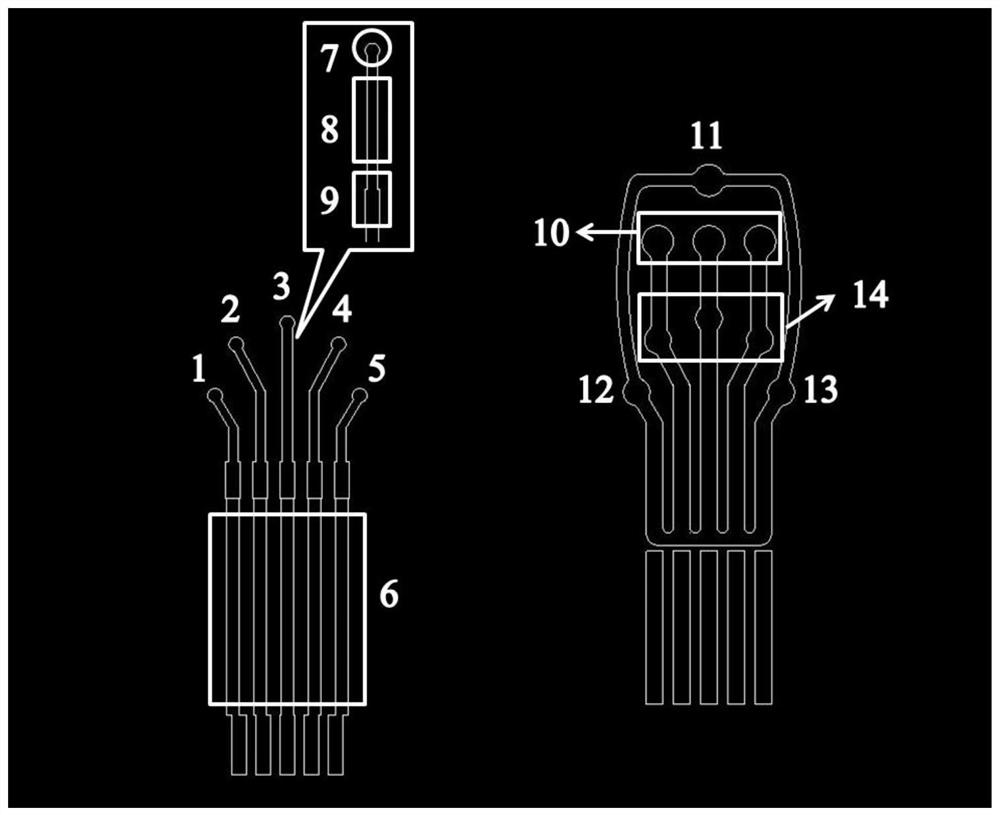

[0045] Preparation of Zn-TCPP / GO multi-channel microfluidic electrochemical sensor chip:

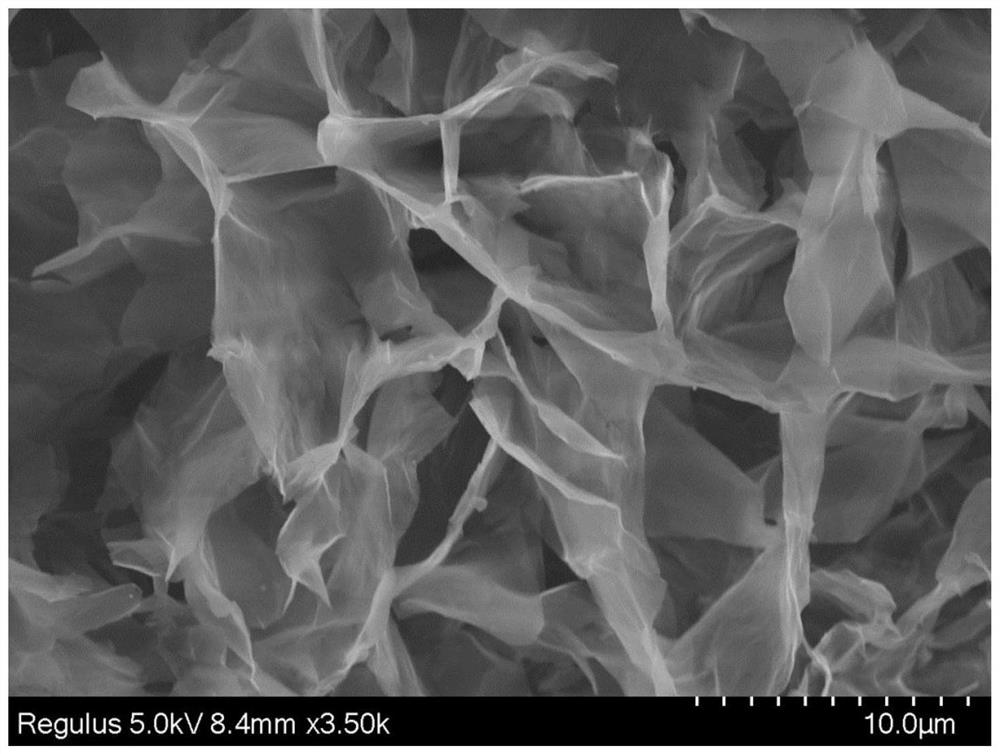

[0046] A. Evenly disperse 5mg of graphene oxide in 13mL of absolute ethanol, after ultrasonic treatment for 10min, obtain a uniform graphene oxide dispersion, and evenly coat the dispersion on the surface of the silicon wafer, and wait for it to dry to form graphite oxide vinyl film layer;

[0047] B, the anhydrous ethanolic solution of the anhydrous zinc acetate with a concentration of 4mM is coated on the graphene oxide film layer combined on the silicon wafer obtained in step A, and dried to obtain the graphene oxide film layer and the zinc acetate film layer combined successively. Silicon wafer; then calcined at 350°C for 30 minutes, take out the silicon wafer and cool it naturally to obtain a silicon wafer combined with zinc oxide / graphene oxide composite material;

[0048] C. In a system with anhydrous ethanol:N,N-dimethylformamide (DMF) volume ratio of 3:1, it is formulated to co...

Embodiment 2

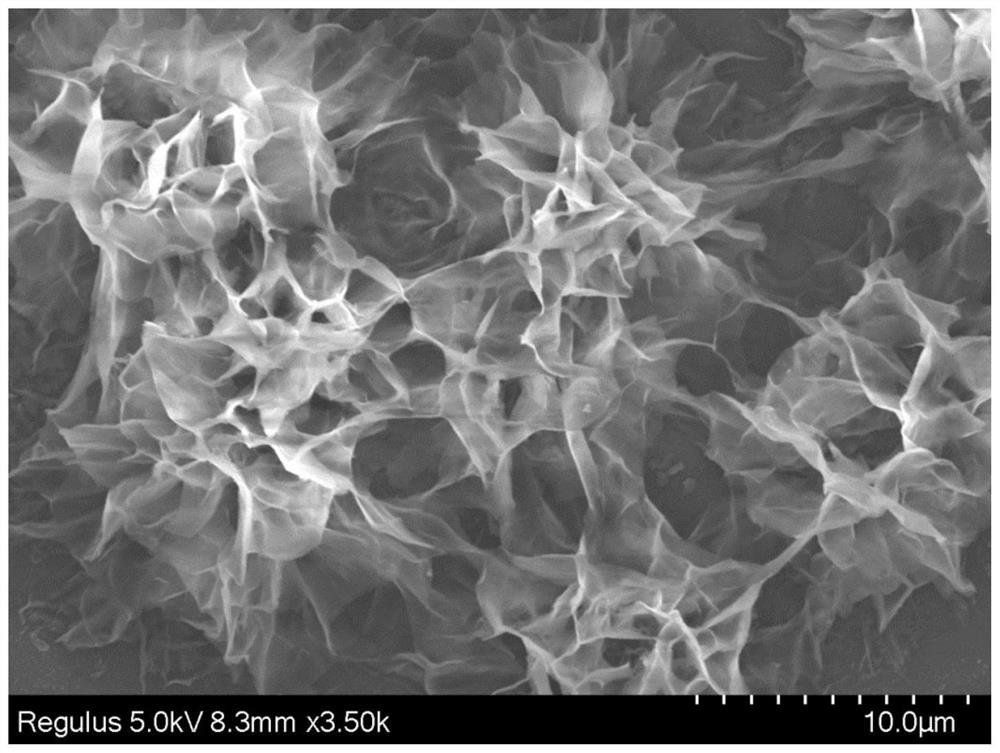

[0055] Preparation of Cu-TCPP / GO multi-channel microfluidic electrochemical sensor chip:

[0056] A. 5mg graphene oxide is uniformly dispersed in 13mL absolute ethanol, after ultrasonic treatment for 10min, a uniform graphene oxide dispersion solution is obtained, the dispersion solution is evenly coated on the surface of the silicon wafer, and it is dried to form graphite oxide vinyl film layer;

[0057] B. the dehydrated ethanol solution of the anhydrous zinc acetate with a concentration of 4mM is coated on the graphene oxide film layer combined on the silicon wafer obtained in step A, and dried to obtain the graphene oxide film layer and the zinc acetate film layer in combination successively. Silicon wafer; then calcined at 350°C for 30 minutes, take out the silicon wafer and cool it naturally to obtain a silicon wafer combined with zinc oxide / graphene oxide composite material;

[0058] C. In a system with anhydrous ethanol:N,N-dimethylformamide (DMF) volume ratio of 3:1,...

Embodiment 3

[0065] The multi-channel microfluidic electrochemical sensor chip prepared in Example 1 detects goat anti-human IgG:

[0066] A. The ProteinA / PBS solution (pH=7.4) was injected into the electrochemical sensor chip channel through the injection tank I 10, and then the electrochemical sensor chip was incubated at 4°C overnight. ProteinA and the multi-channel electrode chip surface metal Ion complexation plays a role as a bridge for subsequent immobilization of antibodies;

[0067] B, the phosphate buffered saline solution is slowly passed into the electrochemical sensor chip channel through the injection pool II 11 to clean the entire channel;

[0068] C. Inject the goat anti-human IgG antibody / PBS solution into the channel of the electrochemical sensor chip through the injection pool I 10, requiring the previous phosphate buffered saline solution in the channel to be discharged from the channel, and then place the electrochemical sensor chip at 37 ° C. Incubate for 1 h, and bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com