Splicing type construction method of wall

A construction method and splicing technology, applied in building structures, protective buildings/shelters, walls, etc., can solve the problems of waste of wall panel performance, weak impact resistance, and insufficient performance of wall panels. The effect of improving construction efficiency, increasing compressive strength, and shortening wall construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

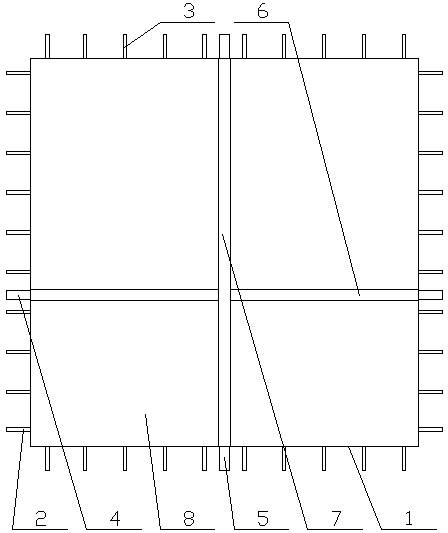

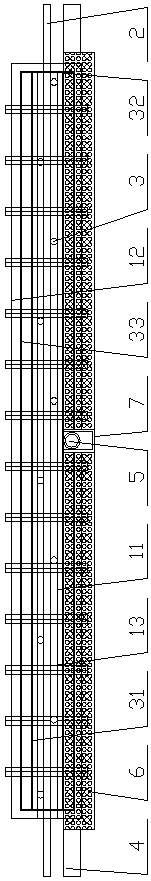

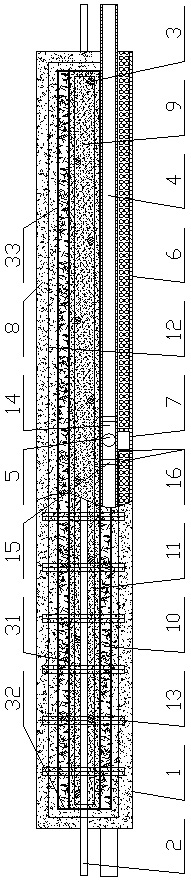

[0138] First, manufacture the prefabricated wall panel 1 according to the construction requirements of the wall, including the following steps:

[0139] 01) The core board cage body 11 is formed by splicing and welding steel bars, and then the horizontal pretensioning ties 2, the vertical pretensioning ties 3 and the horizontal longitudinal connecting ribs 13 are respectively fixed and connected in the core board cage 11.

[0140] The vertical pre-tensioning ties 3 are respectively staggered and evenly fixed on both sides of the core board cage 11 , and the horizontal pre-tensioning ties 2 are fixedly connected to the vertical ties respectively provided on both sides of the core board cage 11 . Between the pre-tensioning ties 3, the horizontal longitudinal connecting rib 13 is perpendicular to the horizontal pre-tensioning ties 2 and the vertical pre-tensioning ties 3 respectively.

[0141] 02) Each end face of the core board cage body 11 is fixed with a pouring template, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com