Super-hydrophilic anti-dirt self-repairing coating, preparation method of coating and coating

An anti-fouling and self-healing technology, applied in the field of coatings, can solve the problems of being easily damaged, not very satisfactory, and difficult to maintain super-hydrophilicity, so as to achieve the effect of improving hydrophilicity and improving hydrophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

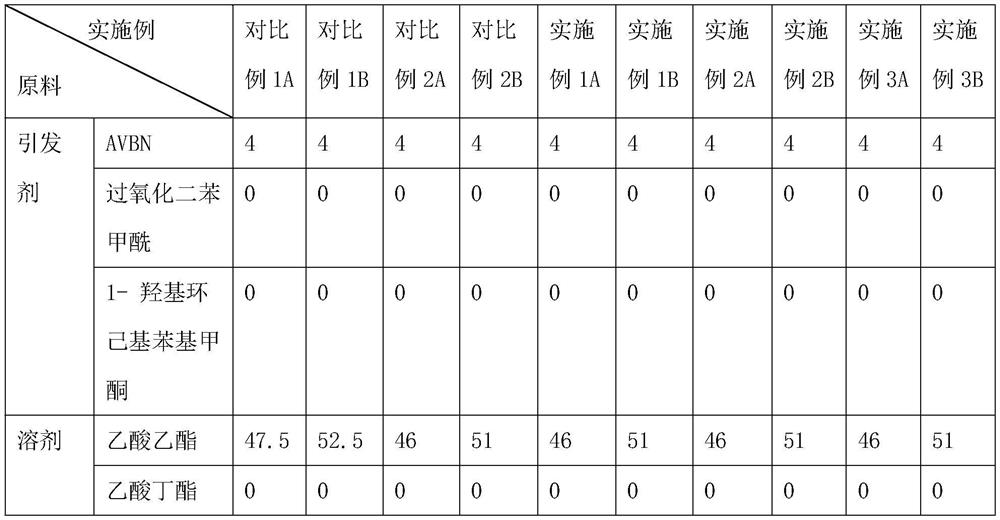

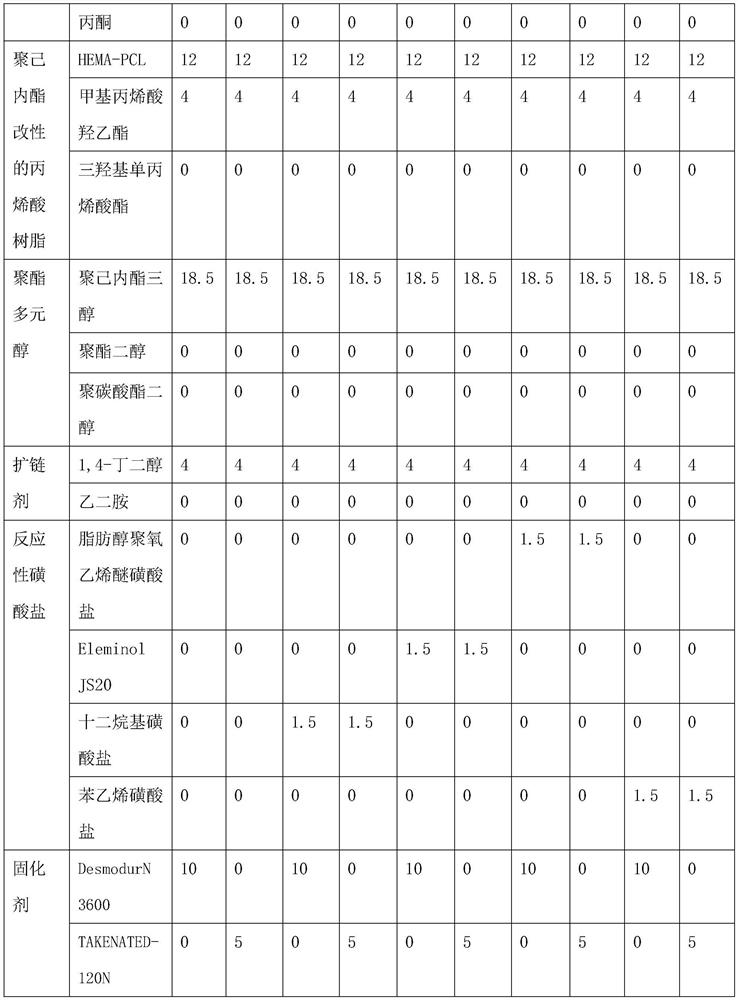

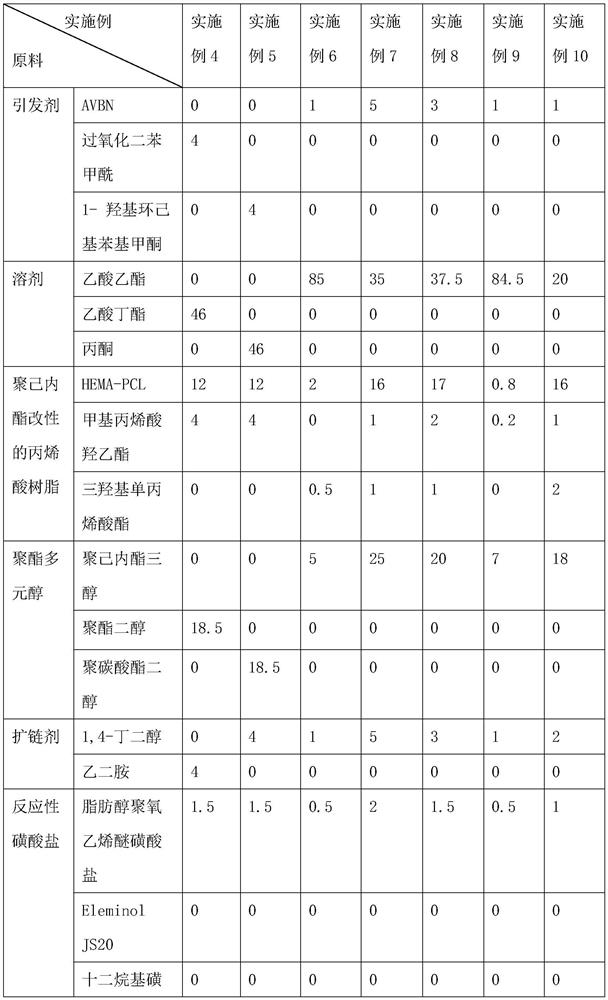

[0027]In this embodiment, the initiator is azobisisoheptanenitrile (AVBN), West Asia Chemical. The polycaprolactone-modified acrylic resins are polycaprolactone-modified methacrylate and hydroxyethyl methacrylate, wherein the polycaprolactone-modified methacrylate and hydroxyethyl methacrylate are The mass ratio was 12:4, polycaprolactone-modified polyhydroxyethyl methacrylate (HEMA-PCL), Xi'an Qiyue Biotechnology; hydroxyethyl methacrylate (HEMA), Aladdin. The polyester polyol is polycaprolactone triol PCL2000, BASF. The reactive sulfonate is alkyl allyl succinate sulfonate, Eleminol JS20, Sanyo Chemicals, Japan. The chain extender is 1,4-butanediol. The isocyanate curing agent is an HDI trimer curing agent, and the HDI trimer curing agent is specifically Desmodur N3600 of the German Covestro Group.

[0028] The preparation method of the superhydrophilic antifouling self-healing coating comprises the following steps:

[0029] Step S1, add 40g ethyl acetate to the reaction...

Embodiment 1B

[0033] The same parts of Example 1B and Example 1A omit the same description, and the difference between Example 1B and Example 1A is that the isocyanate curing agent is HXDI trimer curing agent, and the HXDI trimer curing agent is Japan Mitsui Chemicals Co., Ltd. The TAKENATE D-120N. In step S2, 5 g of curing agent TAKENATED-120N and 11 g of ethyl acetate were added.

Embodiment 2A

[0035] The same parts of Example 2A and Example 1A are omitted, and the difference between Example 2A and Example 1A is: the reactive sulfonate is fatty alcohol polyoxyethylene ether sulfonate, fatty alcohol polyoxyethylene ether sulfonic acid Salt is produced by Hubei Xinghengye Technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com