Self-cleaning powder coating as well as preparation method and application thereof

A powder coating and self-cleaning technology, applied in powder coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as difficult to clean oil stains, improve self-cleaning durability, improve self-cleaning performance, and increase cross-linking density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

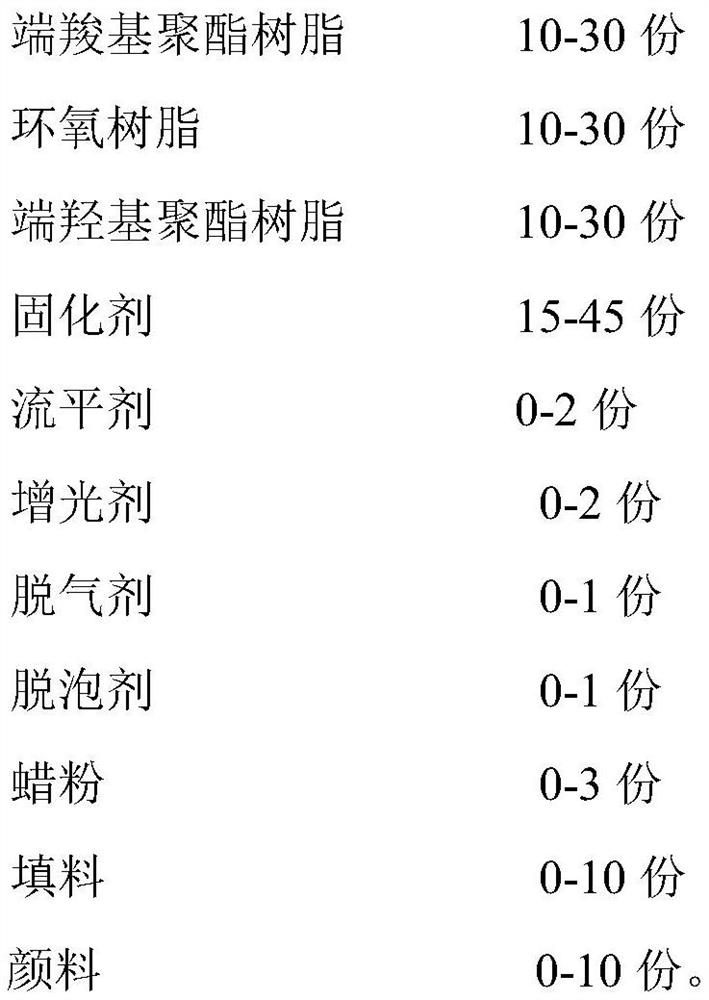

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of self-cleaning powder coating is carried out according to the following steps:

[0027] Step 1, batching and mixing: according to 5 parts of carboxyl-terminated polyester resin, 5 parts of epoxy resin, 30 parts of hydroxyl-terminated polyester resin, 45 parts of isocyanate, 1 part of mixture of acrylate copolymer and silica, 1 part Copolymer of butyl acrylate and methyl methacrylate, 1 part of benzoin (also known as benzophenone), 1 part of defoaming agent, 3 parts of polytetrafluoroethylene wax, 7 parts of silicon powder, 1 part of pigment Take the raw materials, and pre-mix the raw materials, so that the above-mentioned raw materials are fully mixed evenly, that is, the mixed raw materials are obtained, wherein the acid value of the carboxyl-terminated polyester resin is 60-80 mgKOH / g, and the viscosity (200 ° C) is 2000-5000 mPa .s, the epoxy equivalent of epoxy resin is 700-1000g / eg, the softening point is 88-100℃, the hydroxyl value of hydrox...

Embodiment 2

[0031] A preparation method of self-cleaning powder coating is carried out according to the following steps:

[0032] Step 1, batching and mixing: according to 2 parts of carboxy-terminated polyester resin, 2 parts of epoxy resin, 30 parts of hydroxyl-terminated polyester resin, 45 parts of isocyanate, 1 part of mixture of acrylate copolymer and silica, 1 part Copolymer of butyl acrylate and methyl methacrylate, 1 part of benzoin (also known as benzophenone), 1 part of defoaming agent, 3 parts of polytetrafluoroethylene wax, 13 parts of silicon powder, 1 part of pigment Take the raw materials, and premix the raw materials, so that the above-mentioned raw materials are fully mixed to obtain the mixed raw materials, wherein the carboxyl-terminated polyester resin has a fatty acid value of 60-80 mgKOH / g, and a viscosity (200 ° C) of 2000-5000mPa. s, the epoxy equivalent of epoxy resin is 700-1000g / eg, the softening point is 88-100℃, the hydroxyl value of hydroxyl-terminated polye...

Embodiment 3

[0036] A preparation method of self-cleaning powder coating is carried out according to the following steps:

[0037] Step 1, batching and mixing: according to 5 parts of carboxyl-terminated polyester resin, 5 parts of epoxy resin, 32 parts of hydroxyl-terminated polyester resin, 48 parts of isocyanate, 1 part of mixture of acrylate copolymer and silica, 1 part of Copolymer of butyl acrylate and methyl methacrylate, 1 part of benzoin (also known as benzophenone), 1 part of defoaming agent, 3 parts of polytetrafluoroethylene wax, 2 parts of silicon powder, 1 part of pigment Take the raw materials, and pre-mix the raw materials, so that the above-mentioned raw materials are fully mixed evenly, that is, the mixed raw materials are obtained, wherein the acid value of the carboxyl-terminated polyester resin is 60-80 mgKOH / g, and the viscosity (200 ° C) is 2000-5000 mPa .s, the epoxy equivalent of epoxy resin is 700-1000g / eg, the softening point is 88-100℃, the hydroxyl value of hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com