Packaging flame-retardant coating for aerogel and production process of packaging flame-retardant coating

A flame-retardant coating and airgel technology, which is applied in the direction of fire-resistant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc. Improve the flame retardant effect, excellent adhesion and anti-peeling performance, improve fatigue resistance and aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

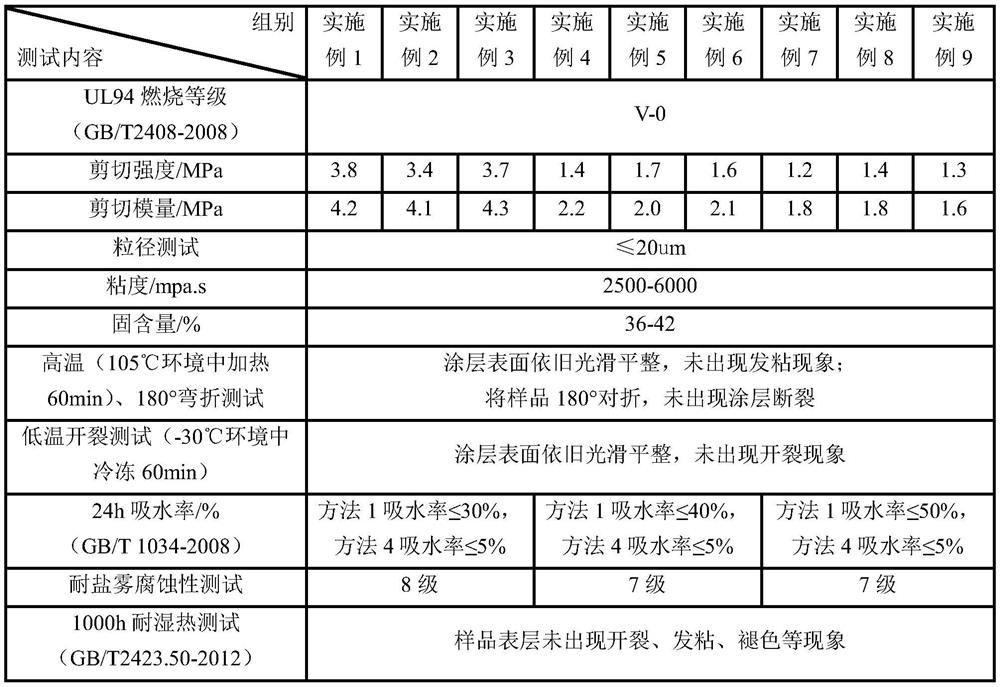

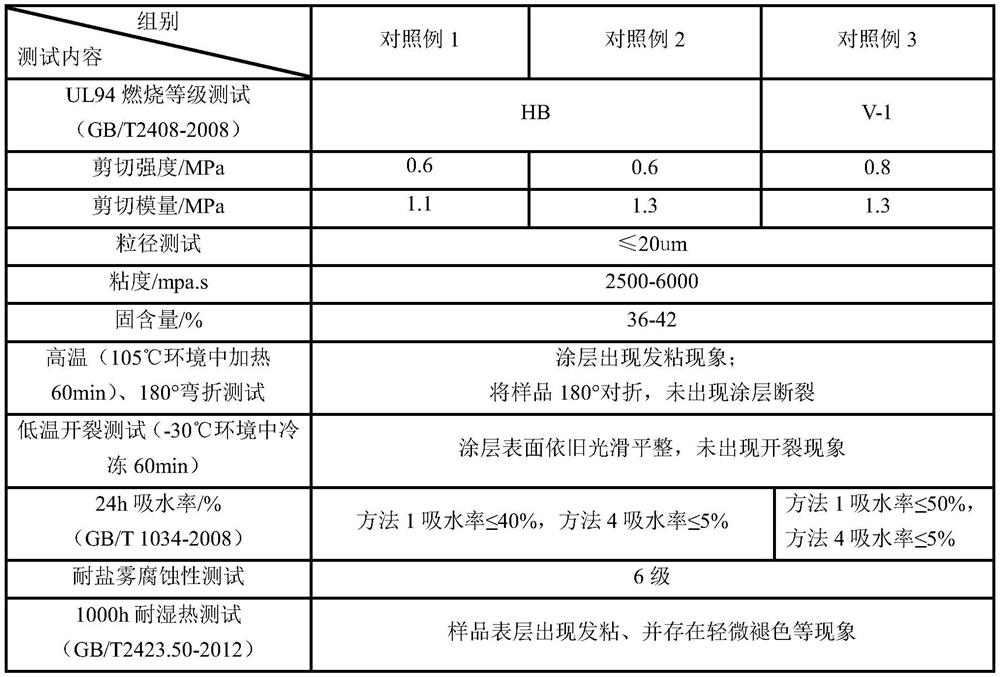

Examples

Embodiment 1

[0037] An encapsulated flame retardant coating for aerogel, in parts by mass, the raw material composition includes: 100 parts of Baling Petrochemical CYDW-100 water-based epoxy resin, 70 parts of compound flame retardant, 80 parts of water solvent, and carbon black paste 5 parts, 6.5 parts of chemical additives, 3 parts of Zhongwan WZ-001 thickener, and 25 parts of Baling Petrochemical CYDHD-220 curing agent.

[0038]Among them, in parts by mass, the compound flame retardant includes: 30 parts of melamine, 10 parts of melamine cyanurate, 10 parts of melamine pyrophosphate, and 20 parts of ammonium polyphosphate, and the particle size of each component of the flame retardant is ≥1000 mesh.

[0039] Among them, in parts by mass, chemical additives include: 1 part of silicone defoamer (Germany BYK-025), 1.5 part of ionic polyacrylate leveling agent (Germany BYK381), water-based dispersant (KBORON KRN8217 ) 2 parts, 1010 antioxidant (BASF) 2 parts.

[0040] The production proces...

Embodiment 2

[0047] An encapsulated flame retardant coating for aerogel, in parts by mass, the raw material composition comprises: 100 parts of Baling Petrochemical CYDW-100 water-based epoxy resin, 70 parts of compound flame retardant, 80 parts of water solvent, and carbon black paste 5 parts, 6.5 parts of chemical additives, 3 parts of Zhongwan WZ-001 thickener, and 25 parts of Baling Petrochemical CYDHD-220 curing agent.

[0048] Among them, in parts by mass, the compound flame retardant includes: 20 parts of melamine, 10 parts of melamine pyrophosphate, 5 parts of melamine phosphate, and 35 parts of ammonium dihydrogen phosphate, and the particle size of each component of the flame retardant is ≥1000 mesh.

[0049] Among them, in parts by mass, chemical additives include: 1 part of silicone defoamer (Germany BYK-025), 1.5 part of ionic polyacrylate leveling agent (Germany BYK381), water-based dispersant (KBORON KRN8217 ) 2 parts, 1010 antioxidant (BASF) 2 parts.

[0050] The productio...

Embodiment 3

[0057] An encapsulated flame retardant coating for aerogel, in parts by mass, the raw material composition comprises: 100 parts of Baling Petrochemical CYDW-100 water-based epoxy resin, 70 parts of compound flame retardant, 80 parts of water solvent, and carbon black paste 5 parts, 6.5 parts of chemical additives, 3 parts of Zhongwan WZ-001 thickener, and 25 parts of Baling Petrochemical CYDHD-220 curing agent.

[0058] Among them, in parts by mass, the compound flame retardant includes: 20 parts of melamine cyanurate, 10 parts of melamine pyrophosphate, 10 parts of melamine phosphate, 30 parts of ammonium dihydrogen phosphate, and the particle size of each component of the flame retardant is ≥1000 eye.

[0059] Among them, in parts by mass, chemical additives include: 1 part of silicone defoamer (Germany BYK-025), 1.5 part of ionic polyacrylate leveling agent (Germany BYK381), water-based dispersant (KBORON KRN8217 ) 2 parts, 1010 antioxidant (BASF) 2 parts.

[0060] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com