Preparation method of modified polyvinyl alcohol/thermoplastic resin composite material

A technology of polyvinyl alcohol resin and thermoplastic resin, which is applied in the field of materials and can solve problems such as poor strength and poor water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

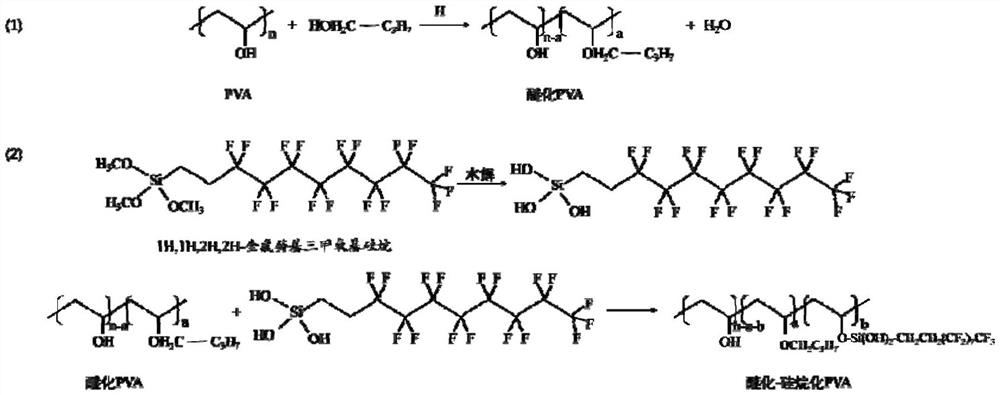

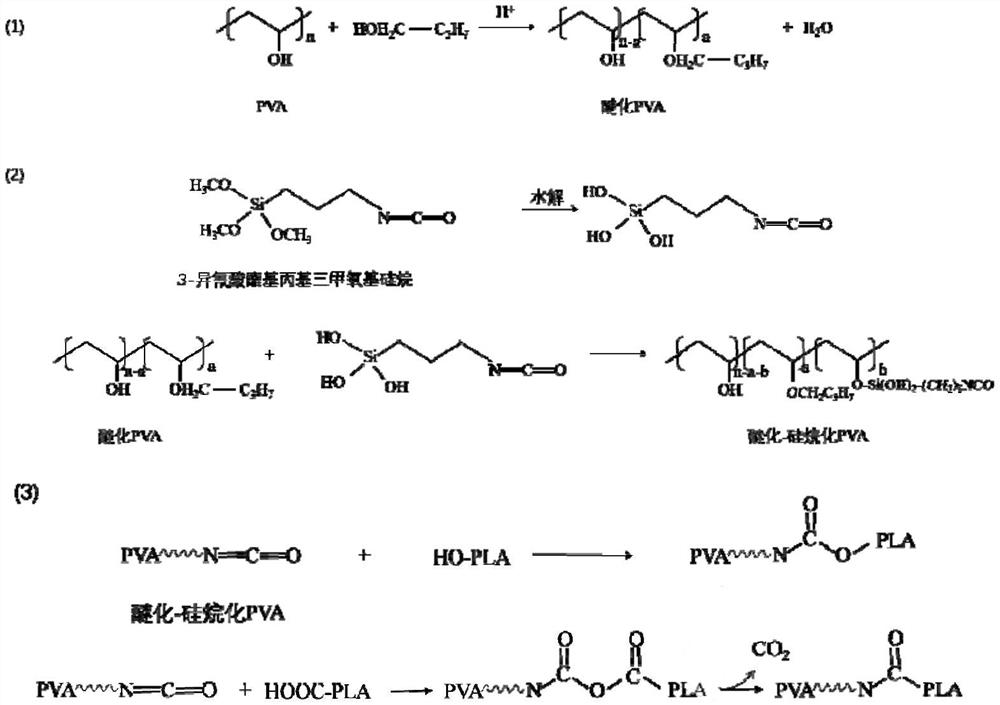

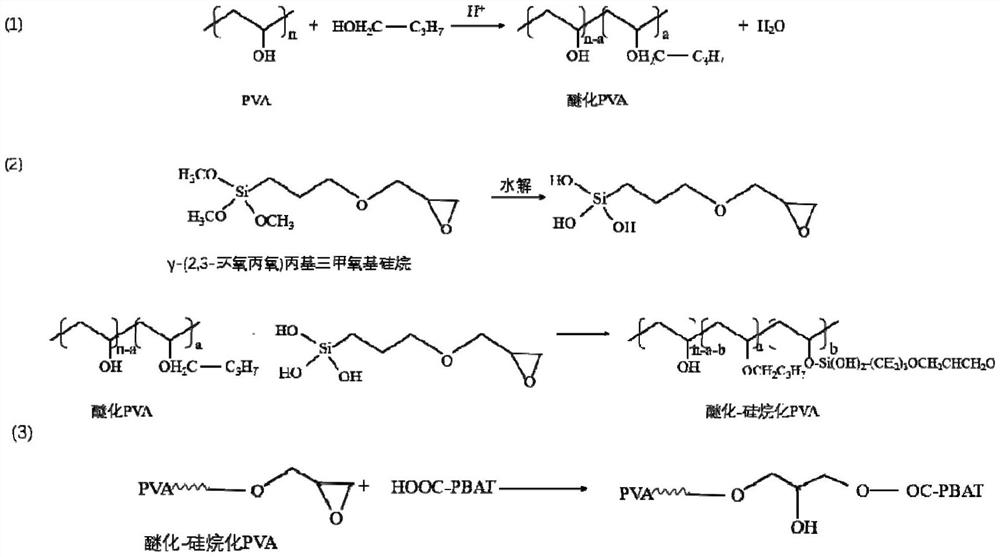

[0025] In an embodiment of the present invention, a method for preparing a modified polyvinyl alcohol / thermoplastic resin composite material comprises the following steps:

[0026] By weight, add 10-80 parts of polyvinyl alcohol resin into 100-800 parts of dimethyl sulfoxide, place it in a constant temperature water bath at 45-55°C, stir evenly, and dissolve to obtain a polyvinyl alcohol resin solution, which is added dropwise. 1-10 parts of concentrated sulfuric acid, add 1-70 parts of fatty alcohol, react for 1-4 hours, then filter under reduced pressure, pour the filtrate into 400-800 parts of acetone, let stand, the product is precipitated, washed, filtered, and dried to constant weight , to obtain etherified polyvinyl alcohol resin;

[0027] In parts by weight, add 10-80 parts of etherified polyvinyl alcohol resin into 100-800 parts of deionized water to dissolve or swell for 2-5 hours, at a constant temperature of 90-95 ℃, add 1-10 parts of concentrated sulfuric acid dro...

Embodiment 1

[0057] In parts by weight, 50 parts of PVA1788 were added to 400 parts of dimethyl sulfoxide, stirred in a constant temperature water bath at 50°C, and dissolved to obtain a polyvinyl alcohol resin solution, 2 parts of concentrated sulfuric acid was added dropwise, 30 parts of n-butanol were added, and the reaction was carried out for 3 hours. . Filtration under reduced pressure, pouring the filtrate into 400 parts of acetone, standing, the product was precipitated, washed, filtered, dried to constant weight, and the polyvinyl alcohol resin was etherified.

[0058] In parts by weight, 50 parts of etherified polyvinyl alcohol resin was added to 500 parts of deionized water to swell for 3 hours. At a constant temperature of 92 °C, 1 part of concentrated sulfuric acid was added dropwise, and 30 parts of 1H, 1H, 2H, 2H-perfluorodecyltrimethyl were added. Oxysilane was stirred for 4 hours under nitrogen, filtered under reduced pressure, the filtrate was poured into 400 parts of abs...

Embodiment 2

[0063] In parts by weight, 50 parts of PVA1788 were added to 400 parts of dimethyl sulfoxide, stirred in a constant temperature water bath at 50°C, and dissolved to obtain a polyvinyl alcohol resin solution, 2 parts of concentrated sulfuric acid was added dropwise, 30 parts of n-butanol were added, and the reaction was carried out for 3 hours. . Filtration under reduced pressure, pouring the filtrate into 400 parts of acetone, standing, the product was precipitated, washed, filtered, and dried to constant weight to obtain etherified polyvinyl alcohol resin.

[0064] In parts by weight, 50 parts of etherified polyvinyl alcohol resin was added to 500 parts of deionized water to swell for 3 hours, and at a constant temperature of 92 °C, 1 part of concentrated sulfuric acid was added dropwise, 30 parts of 3-isocyanatopropyltrimethoxysilane was added, and nitrogen was purged. The reaction was stirred for 4h. Filtration under reduced pressure, pouring the filtrate into 400 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com