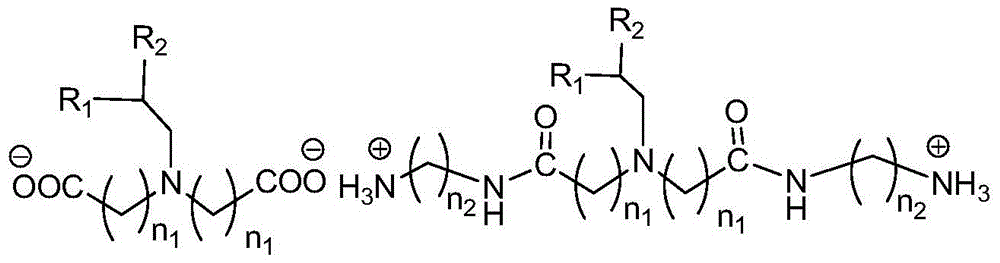

A kind of novel branched fatty nylon salt and its preparation method and application

A technology of nylon salt and branching, which is applied in the field of new branched fatty nylon salt and its preparation, which can solve the problems of product color yellowing, lack, and inapplicability, and achieve high-temperature viscosity and intrinsic viscosity reduction and steric hindrance increase big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

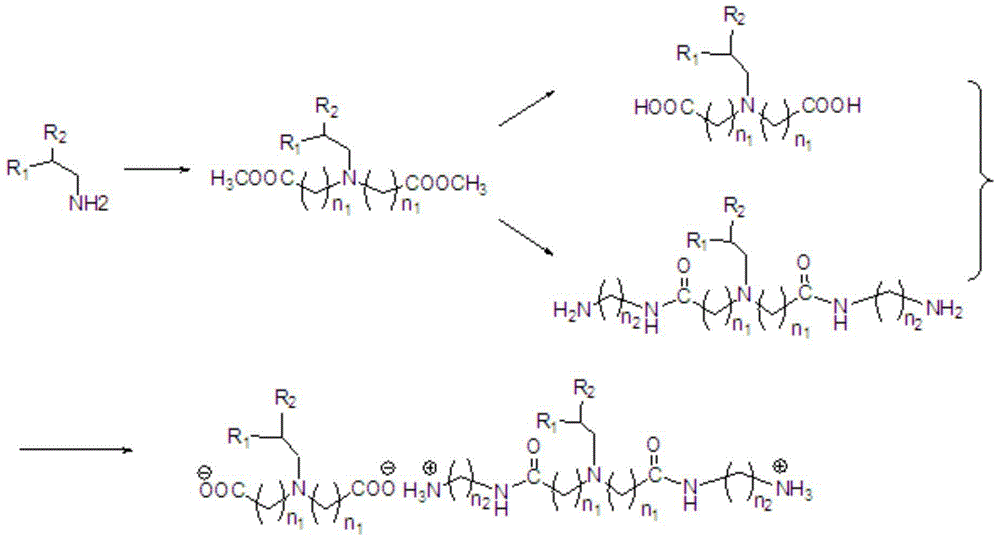

Method used

Image

Examples

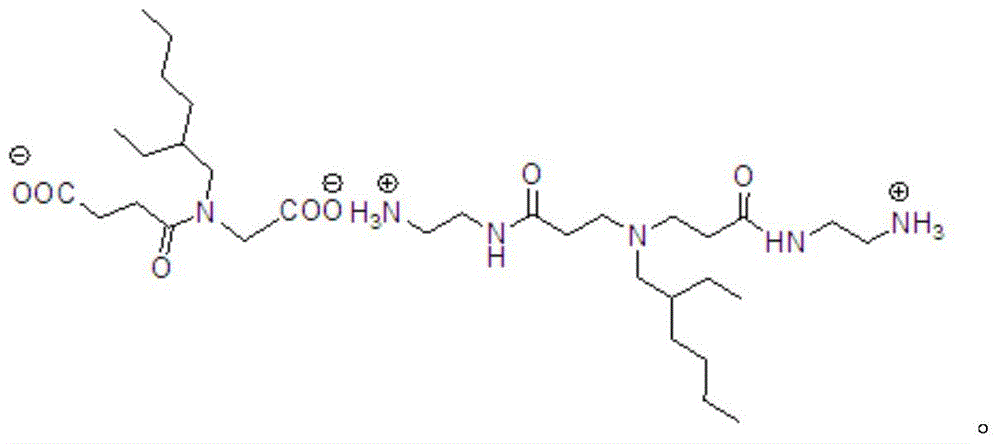

Embodiment 1

[0041] Synthesis of N,N-Dimethyl Dipropionate-N-Isooctylamine.

[0042] Weigh 433.1 g of isooctylamine, add it to a three-necked flask with mechanical stirring and condenser, and dissolve it with 500 mL of anhydrous methanol. At a certain temperature, 865.5g of methyl acrylate was slowly added dropwise, kept at the temperature for 24h, and the reaction was tracked by spot plate and GC. After the reaction, the solvent and excess methyl acrylate were removed by distillation under reduced pressure to obtain a crude product. The target product N,N-dipropionic acid methyl ester-N-isooctylamine was obtained by vacuum distillation and separation. The yield was 99.3%.

[0043] 1 H NMR(400MHz, CDCl 3 )δ3.65(s,6H),2.76-2.67(m,4H),2.41(t,J=8.0Hz,4H), 2.17(dd,J=7.1,1.1Hz,2H),1.38(s,1H ),1.34–1.15(m,8H),0.87(t,J=8.0Hz,3H),0.81(t,J=8.0Hz,3H).ESI-MS(35eV, m / Z): 324.20[M+ Na, 25], 302.24 [M+H, 75], 228.24 [M-C3H6O2, 100]

[0044] IR: 2943cm -1 The stretching vibration peak of -CH2, 1739cm -1 It...

Embodiment 2

[0046] Synthesis of N,N-dipropionic acid-N-isooctylamine.

[0047] Weigh 500 g of N,N-dimethyl dipropionate-N-isooctylamine, add it to a three-necked flask with mechanical stirring and condenser, and dissolve it with 1L of anhydrous methanol. Weigh 928.0 g of potassium hydroxide into a saturated aqueous solution and add it to the reaction flask. The temperature was increased, the reaction was refluxed for 6 hours, and the reaction process was followed by GC. After the reaction, the pH was adjusted to 7 with 10% hydrochloric acid solution. Rotary evaporation to remove the solvent, repeated washing with absolute ethanol for three times, filtration to remove insoluble matter, and rotational evaporation to remove the solvent to obtain N,N-dipropionic acid-N-isooctylamine. The yield was 93.2%.

[0048] 1 H NMR(400MHz, D 2 O)δ3.38(d,J=5.2Hz,2H), 3.23(d,J=5.7Hz,1H),3.03(d,J=5.7Hz,1H), 2.92(d,J=5.0Hz,1H ), 2.80 (s, 2H), 2.73 (dd, J = 12.8, 6.4 Hz, 1H), 1.98 (d, J = 4.8 Hz, 2H), 1.81 (d...

Embodiment 3

[0051] Synthesis of N,N-diamide monoamine-N-amine.

[0052] Take 500.0g (1.67mol) of N,N-dipropionate-N-isooctylamine, 500mL of methanol, add it to a 3L reaction flask with mechanical stirring and condenser, heat up to 65℃, and take ethylenediamine 1003.7g (16.7mol) was slowly dropped into the reaction solution, and the temperature was kept for 24h to react. GC followed the reaction until there was no raw material in the reaction. Firstly, methanol was distilled out at normal pressure, and then ethylenediamine was distilled out under reduced pressure to obtain the target product with a yield of 98,0%.

[0053] 1 H NMR(400MHz, CDCl 3 )δ7.37(s,1H), 3.26(dd,J=11.5,5.7Hz,4H), 2.81(t,J=5.9Hz,3H), 2.75–2.69(m,2H), 2.66–2.58(m ,2H),2.47–2.26(m,4H),2.18(m,2H),1.45(s,1H),1.39–1.15(m,8H),0.88(t,J=7.0Hz,3H),0.82( t,J=7.4Hz,3H).ESI-MS (35eV, m / Z): 380.37[M+Na,20], 358.42[M+H,100], 256.23[M-C4H9N2O,5]

[0054] IR: 3286cm -1 For -NH 2 Stretching vibration peak of N-H, 2939cm -1 It is the stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com