Method for producing collagen tripeptide from cow leather

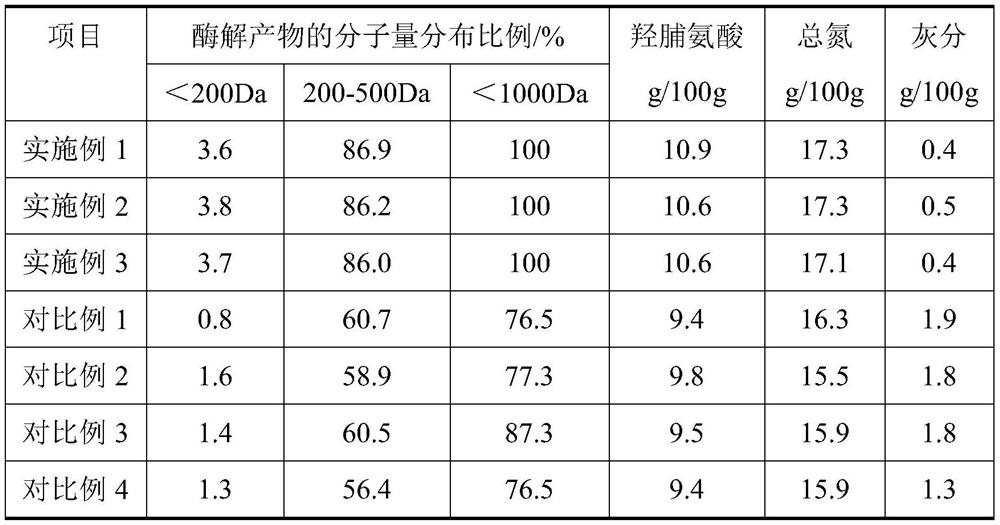

A collagen tripeptide, cowhide technology, applied in the direction of peptides, specific peptides, connective tissue peptides, etc., can solve the problems of low purity, restricting the in-depth development and application of collagen tripeptide, and low yield of collagen tripeptide, and achieve water solubility. Good, shortening the enzymatic hydrolysis time, and the effect of low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for producing collagen tripeptide with cowhide is prepared by the following steps:

[0030] 1) Pretreatment: Take fresh cowhide, clean it, depilate it, cut it into small pieces no larger than 4×4mm, add it to a 5% sodium chloride solution, soak it at room temperature for 1 hour, control the moisture, and add to In 0.1mol / L NaOH solution, stir evenly at 4°C, soak for 3 days, and wash with water for 4 times to obtain pretreated cowhide;

[0031] Said, the weight ratio of cowhide to sodium chloride solution and NaOH solution is 1:5:4.

[0032] 2) Denaturation treatment: Mix the pretreated cowhide and water in a mass ratio of 1:5, boil at 100°C for 25min under 0.9MPa, cool down to 55°C, filter out the residue with double-layer gauze, and obtain denatured cowhide;

[0033] 3) Excitation treatment: add the modified cowhide to the excitation solution, soak it at 40°C for 40min, heat it up to 83°C, keep it for 4min, naturally cool to room temperature, wash with water,...

Embodiment 2

[0043] A method for producing collagen tripeptide with cowhide is prepared by the following steps:

[0044] 1) Pretreatment: Take fresh cowhide, clean it, remove hair, cut it into small pieces no larger than 4×4mm, add it to a sodium chloride solution with a mass fraction of 3%, soak it at room temperature for 1 hour, control the moisture, and add to In 0.1mol / L NaOH solution, stir evenly at 5°C, soak for 2 days, and wash with water for 5 times to obtain pretreated cowhide;

[0045] Said, the weight ratio of cowhide to sodium chloride solution and NaOH solution is 1:4:3.

[0046] 2) Denaturation treatment: mix the pretreated cowhide and water in a mass ratio of 1:5, boil at 100°C for 30min under the condition of 1.0MPa, cool down to 50°C, filter out the residue with double-layer gauze, and obtain the denatured cowhide;

[0047] 3) Excitation treatment: add the modified cowhide to the excitation solution, soak it at 35°C for 50 minutes, raise the temperature to 80°C, keep it f...

Embodiment 3

[0057] A method for producing collagen tripeptide with cowhide is prepared by the following steps:

[0058] 1) Pretreatment: Take fresh cowhide, clean it, depilate it, cut it into small pieces no larger than 4×4mm, add it to a sodium chloride solution with a mass fraction of 7%, soak it at room temperature for 1 hour, control the moisture, and add to In 0.1mol / L NaOH solution, stir evenly at 3°C, soak for 4 days, and wash with water for 3 times to obtain pretreated cowhide;

[0059] Said, the weight ratio of cowhide to sodium chloride solution and NaOH solution is 1:6:5.

[0060] 2) Denaturation treatment: mix the pretreated cowhide and water in a mass ratio of 1:5, boil at 100°C for 20min under 0.8MPa, cool down to 60°C, filter out the residue with double-layer gauze, and obtain denatured cowhide;

[0061] 3) Excitation treatment: add the modified cowhide to the excitation solution, soak for 30 minutes at 45°C, heat up to 85°C, hold for 3 minutes, naturally cool to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com