Hybrid laminate structure of new energy automobile battery shell and preparation method

A technology for new energy vehicles and battery shells, applied in structural parts, battery pack parts, chemical instruments and methods, etc., can solve the problems of complicated welding process, large number of additional components, poor sealing, etc., to improve integration efficiency, improve Surface Quality and Productivity, Quantity Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

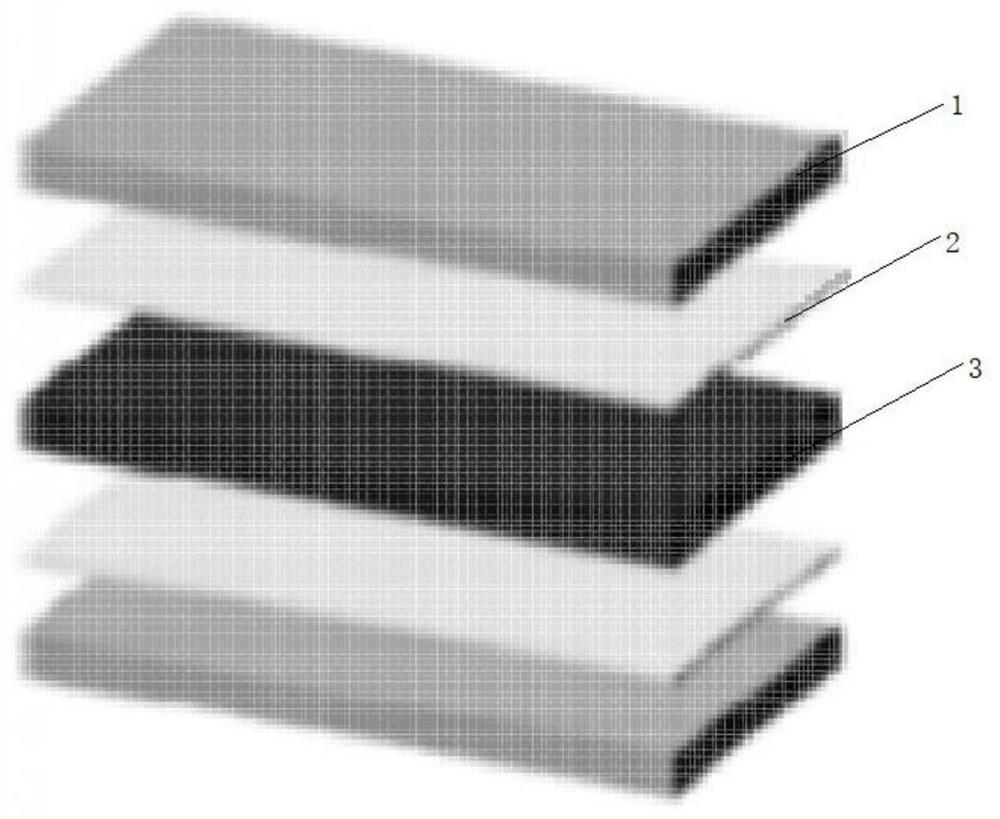

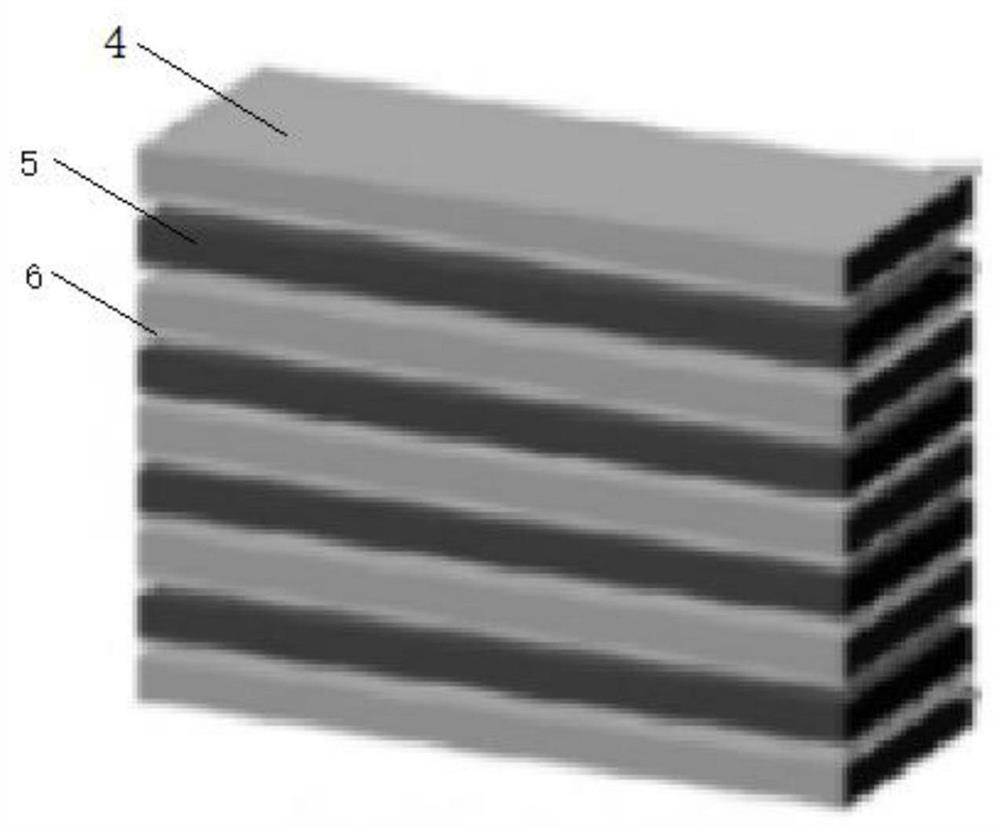

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0029] The purpose of the present invention is to provide a light-weight and high-strength hybrid laminate structure of a new energy vehicle battery case and an integrated molding method for the battery case, so as to solve the above-mentioned problems in the prior art, reduce the use cost, improve the integration efficiency, and improve the battery The use performance and processing efficiency of the shell can meet the development tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com