Integrated ultrasonic welding machine for welding battery cell pole

An ultrasonic welding, integrated technology, applied in the direction of welding/welding/cutting items, welding equipment, welding equipment, etc., can solve the problems of non-standard welding quality of tabs, difficulty in guaranteeing welding quality, inconsistent appearance of battery products, etc. Achieve the effect of ensuring welding quality and appearance and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

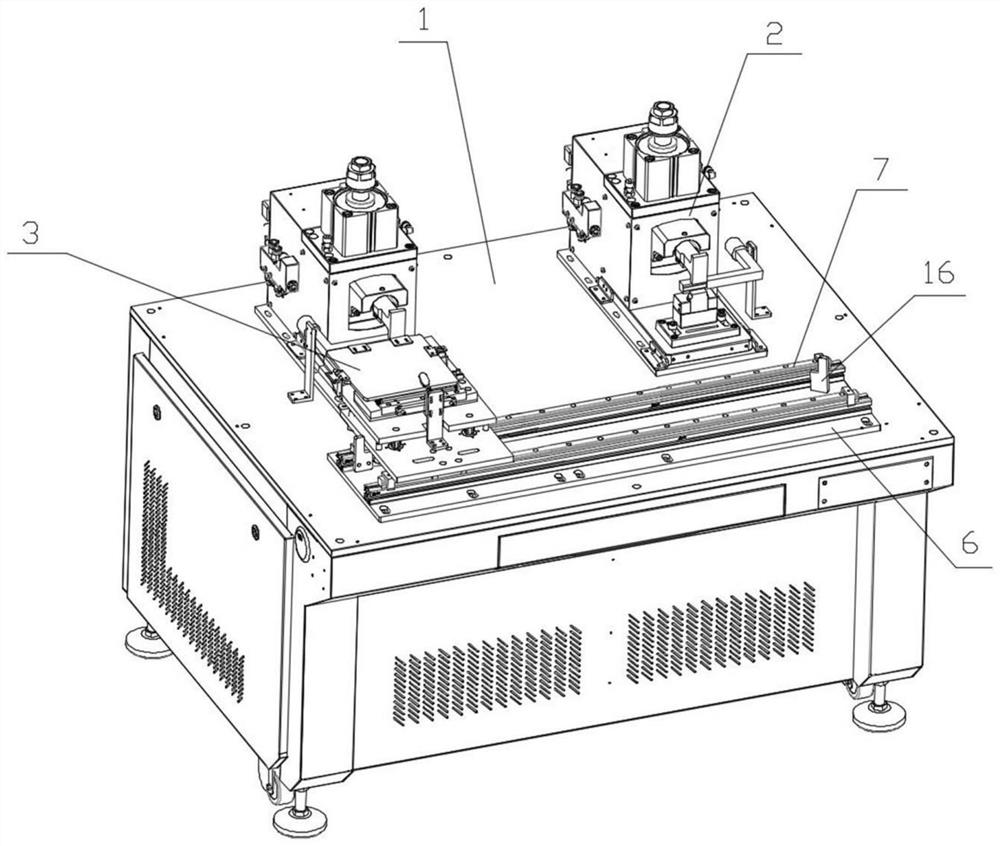

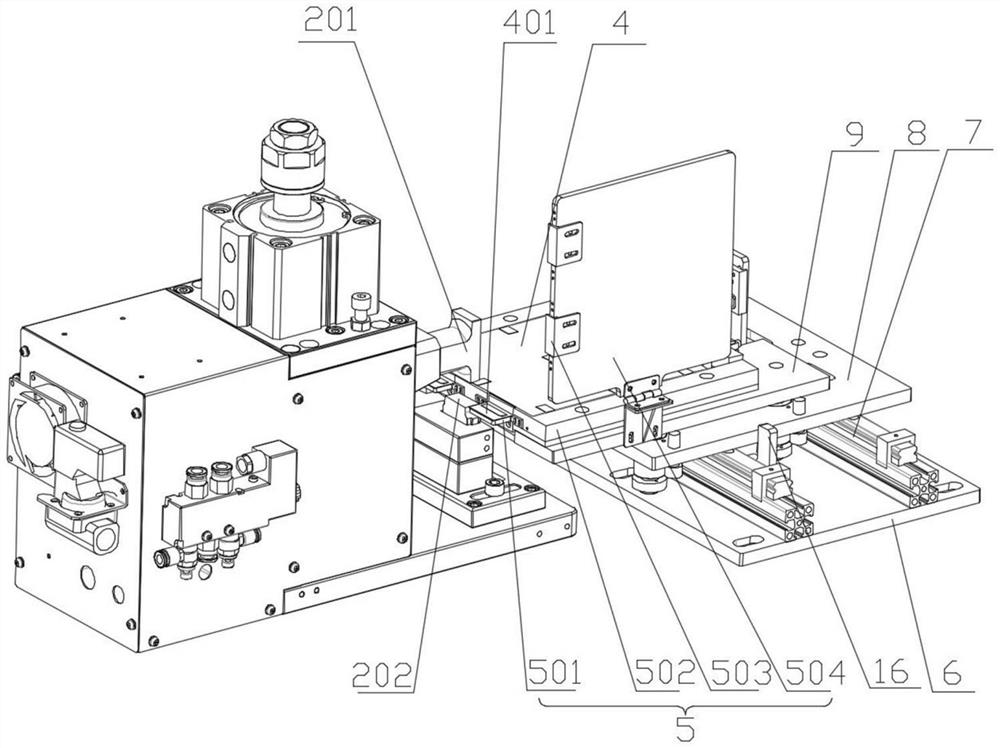

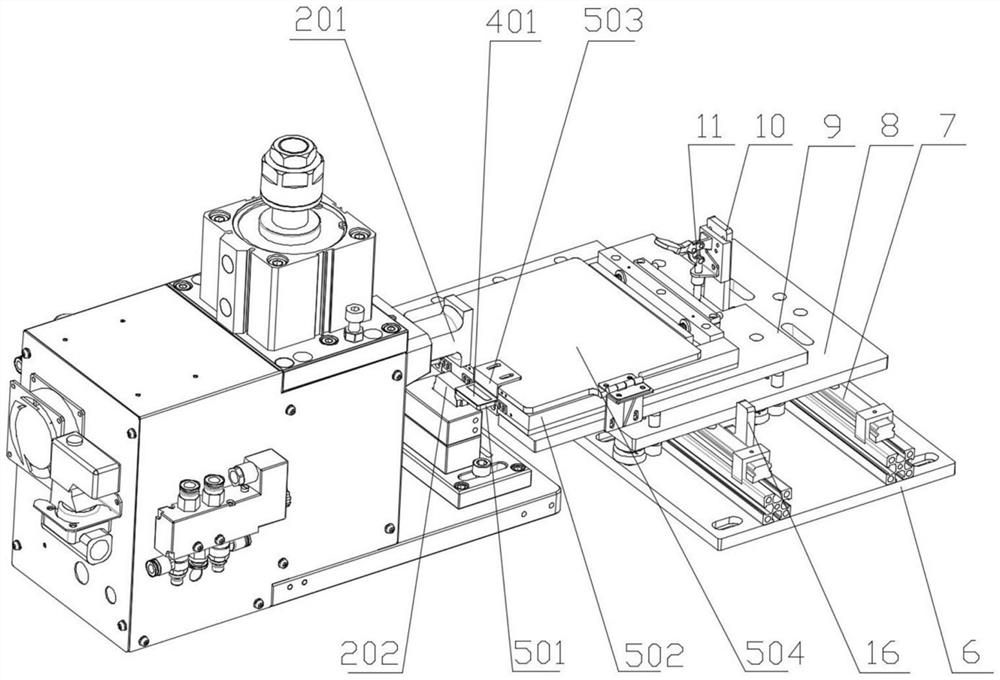

[0021] like figure 1 As shown, an integrated ultrasonic welding machine for the welding of electric core poles of the present invention includes a workbench 1 , two ultrasonic welding devices 2 and one electric core clamping device 3 arranged on the workbench 1 . The two ultrasonic welding devices 2 are spaced from left to right, and their welding positions are oriented in the same direction. figure 1 Center facing forward. The two ultrasonic welding devices 2 have the same structure, and the welding parameters of one ultrasonic welding device 2 are adjusted to be used for welding the copper pole 401 of the cell 4, and the welding parameters of the other ultrasonic welding device 2 are adjusted to be used for welding the cell 4. The aluminum pole 401. On the worktable 1, two wire rails 7 are also provided in front of the two ultrasonic welding devices 2 for sliding engagement with the core clamping device 3. The two wire rails 7 are both fixed on the seat plate 6 provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com