Cold-rolled strip steel winding mechanism and winding method

A technology of cold-rolled strip and reel, which is applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc. It can eliminate the hidden dangers of safety, avoid the unwinding, and quickly replace the problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

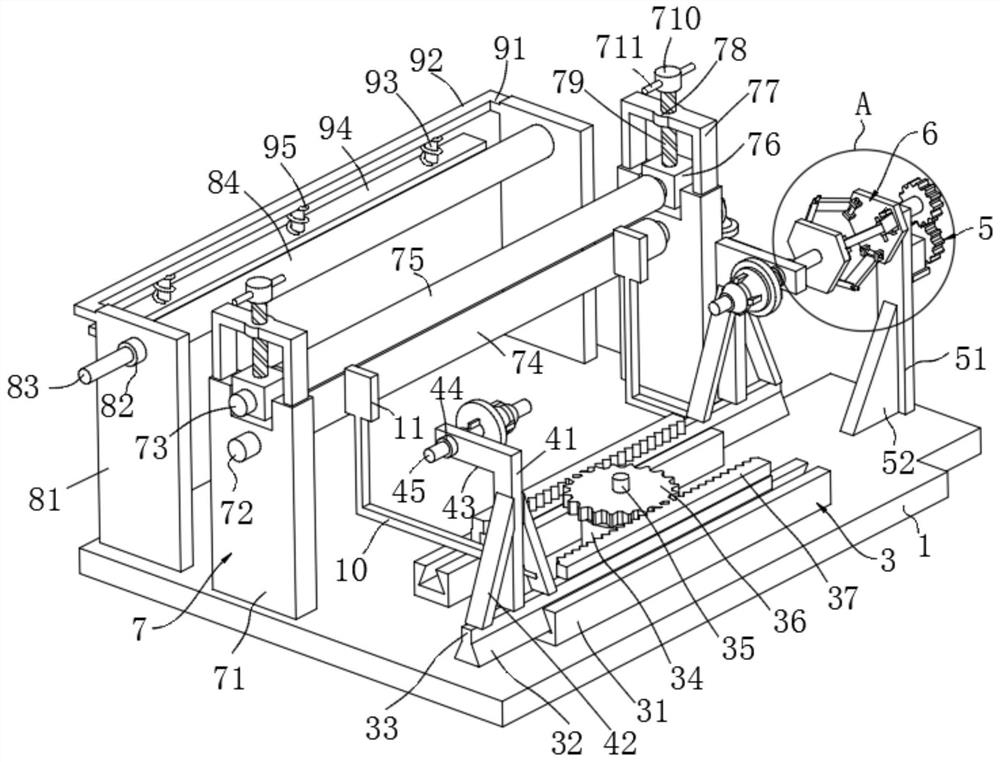

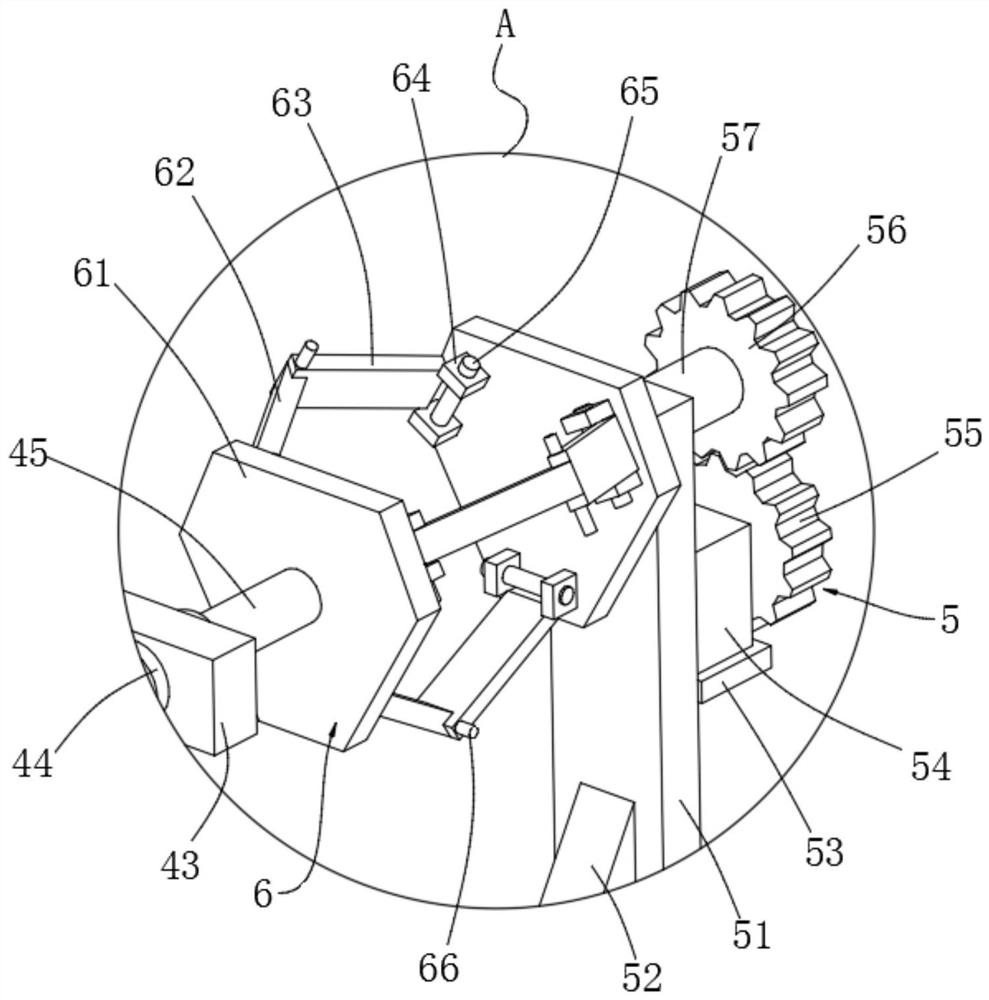

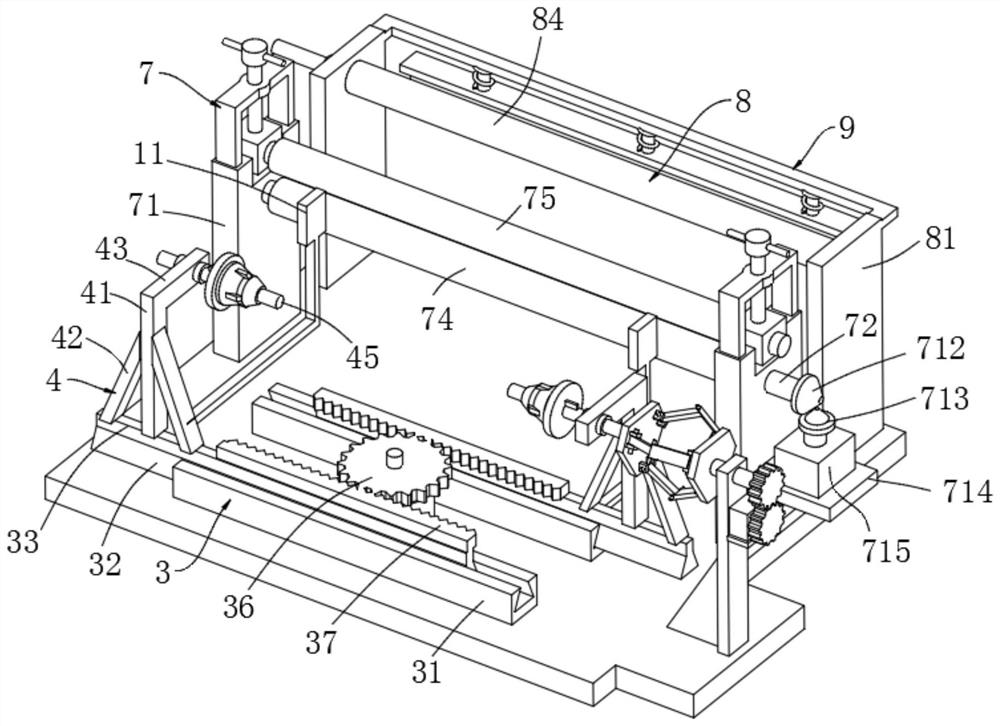

[0041] Example 1, please refer to Figure 1-3 , this embodiment provides a technical solution: a cold-rolled strip steel retracting mechanism, including a mounting plate 1, a reel clamping unit 2, a reel support adjustment unit 3, a reel support unit 4, and a reel rotation power unit 5 and variable length coupling 6;

[0042] The reel support adjustment unit 3 and the reel rotation power unit 5 are respectively installed on the installation plate 1, and the reel rotation power unit 5 drives the external reel installed on the reel support unit 4 to rotate through the length-variable coupling 6;

[0043] The reel support adjustment unit 3 includes a dovetail groove body 31, a dovetail slide bar 32, a fixed bar 33, an adjustment motor 34, an adjustment shaft 35, an adjustment gear 36 and a tooth bar 37; on the plate 1, and the two dovetail grooves 31 are respectively slidably connected with dovetail sliders 32, the two dovetail sliders 32 are respectively fixed with fixed bars 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com