System and method for in-situ pyrolysis of oil-rich coal through steam heat injection

An in-situ pyrolysis and water vapor technology, applied in earthwork drilling, wellbore/well components, mining fluids, etc., can solve problems such as pollution and surface soil pollution, and achieve cost reduction, high energy density, and reduced system design The cumbersome effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

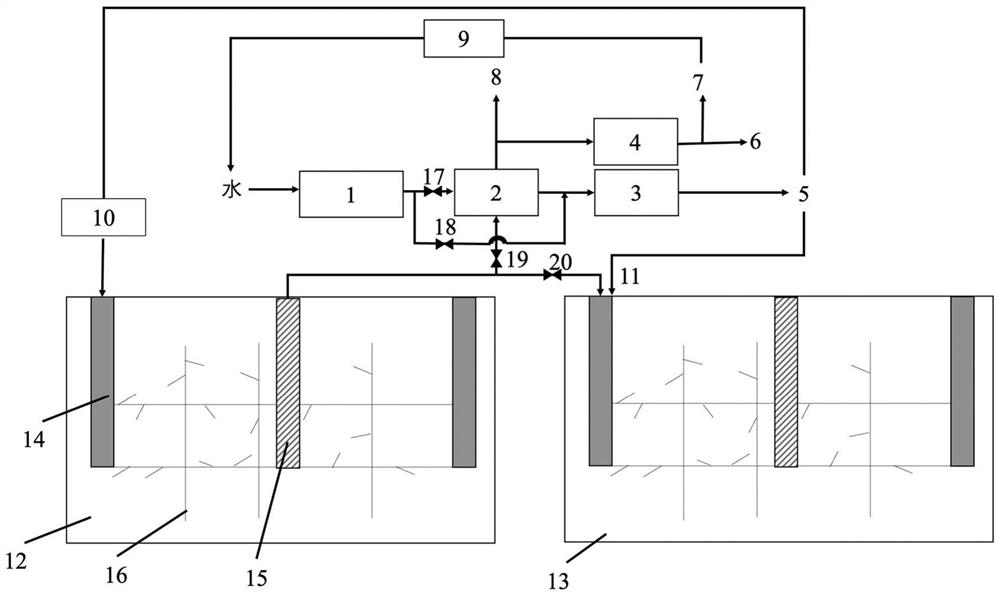

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

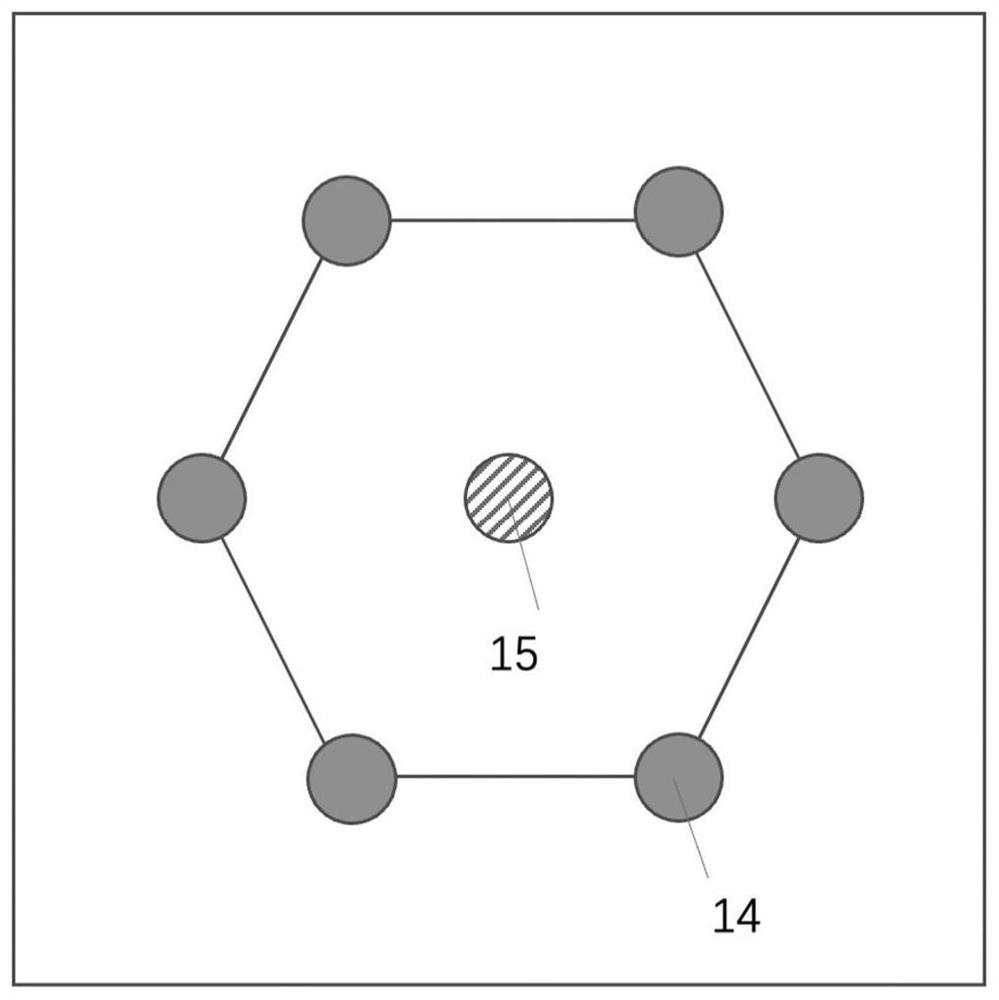

[0029] see figure 1, the present invention provides a system for in-situ pyrolysis of oil-rich coal by steam injection, including a steam generating part composed of a pressurized water pump 1, a condensing heat exchanger 2, a steam generating device 3, and steam 5 of different temperatures , the centrifuge 4, the liquid oil 6, the separation and recovery water 7, the organic gas 8, and the oil-gas-water separation part composed of the water circulation filter device 9; the steam injection 10, the steam supplementary heat 11, the No. No. 13 coal seam block, heat injection well 14, production well 15, coal seam fracturing channel 16, No. 1 valve 17, No. 2 valve 18, No. 3 valve 19, No. 4 valve 20 The in-situ pyrolysis and thermal energy utilization part. The system comprehensively considers the optimization of the in-situ pyrolysis part, the heat energy utilization par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com