Method and system for realizing welding network communication through three-layer switch

A technology of network communication and switch, which is applied in the field of automatic control of automobile welding production line, can solve problems such as inability to realize PLC-PLC communication, complicated lines, redundant ring network, etc., and achieve the effect of reducing hardware network cable links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0073] The first step, the two-layer switch realizes the communication of the following process equipment of the PLC, including the following sub-steps:

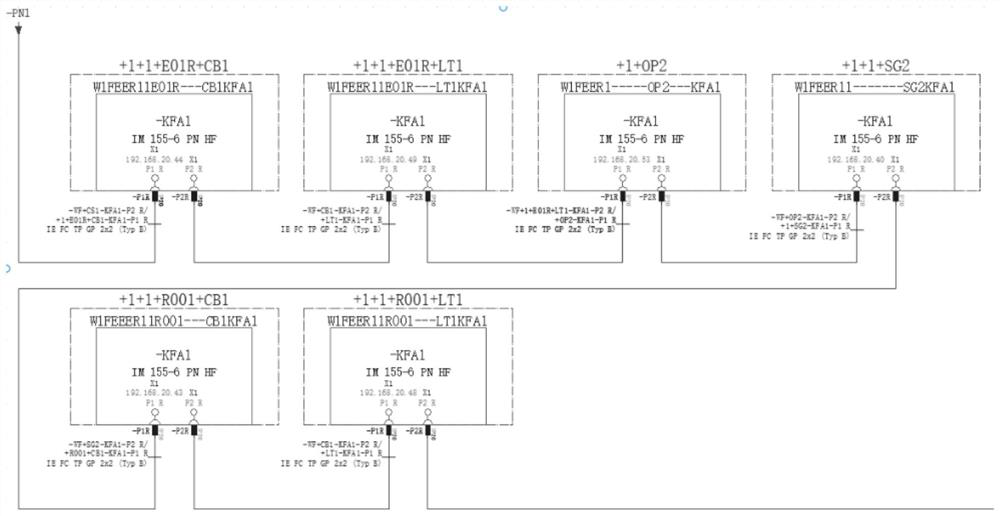

[0074] (1) Hardware design: such as figure 1 As shown in the figure, in the early stage of the EPLAN drawing software, the hardware layout of the equipment that requires communication functions is planned and perfected, and the specific network topology is designed.

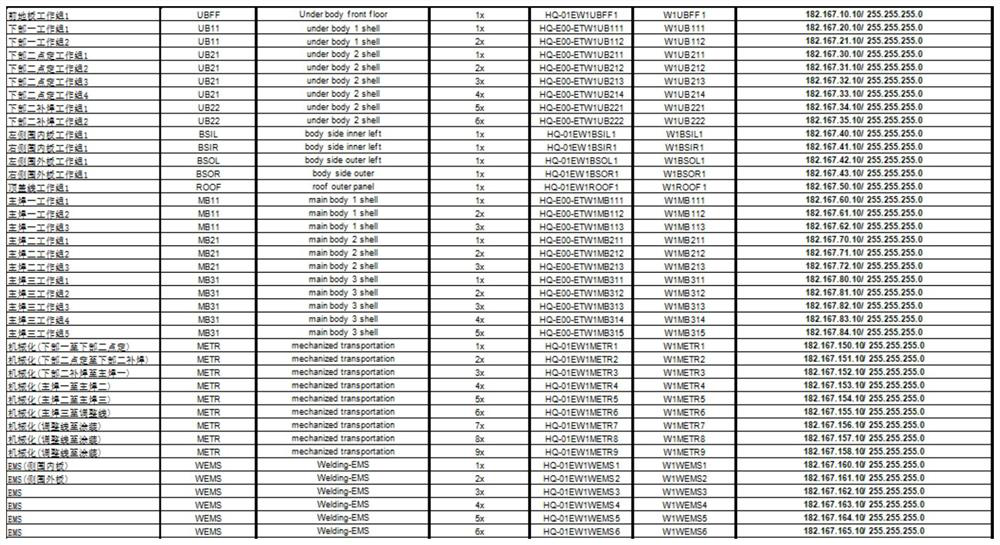

[0075] like figure 2 As shown, in this link, it is necessary to determine the communication connection sequence of the hardware of each device, and to assign a unique IP address to each device that needs to communicate, and to make statistics in the form of a table.

[0076] (2) Software configuration: configure the equipment through Siemens Botu software (PLC programming software). Set the hardware configuration and assign device names to all hardware through the two-layer switch.

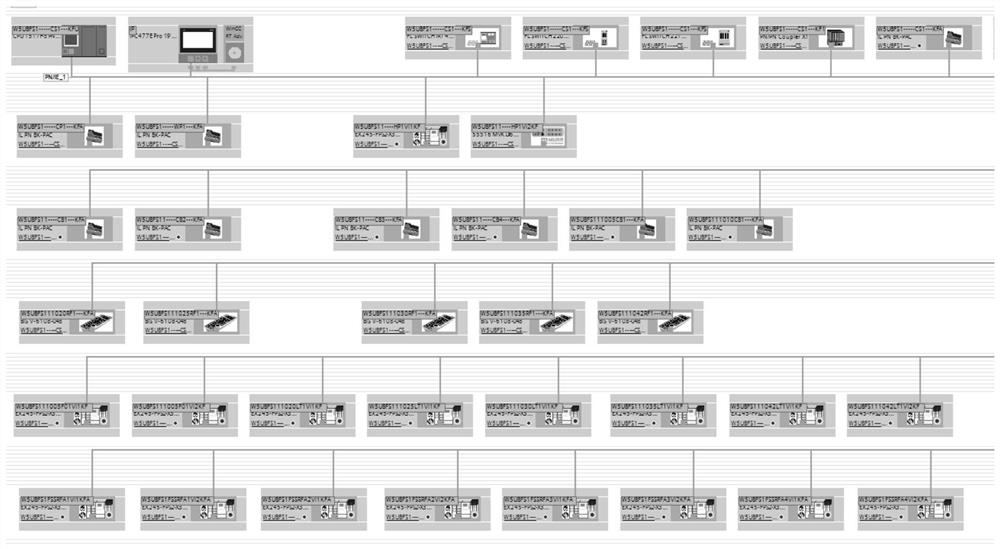

[0077] like image 3 As shown, through this step, all the communication e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com