Multi-parameter coupling once-through boiler pipe blowing steam control method

A once-through boiler and control method technology, applied in the control of superheat temperature, steam superheat, control system, etc., can solve the problems of low steam temperature at the outlet of the superheater, rapid rise of steam pressure at the outlet of the superheater, and long blowing time. Effects of increased temperature, savings in fuel and demineralized water, and reduction in total number of blows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

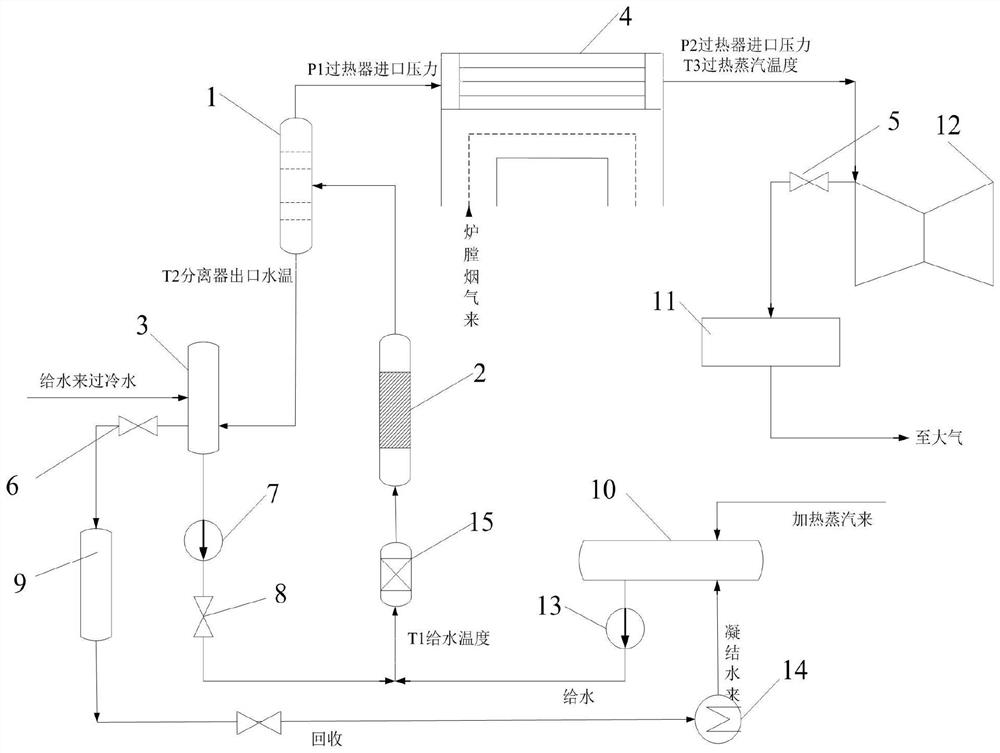

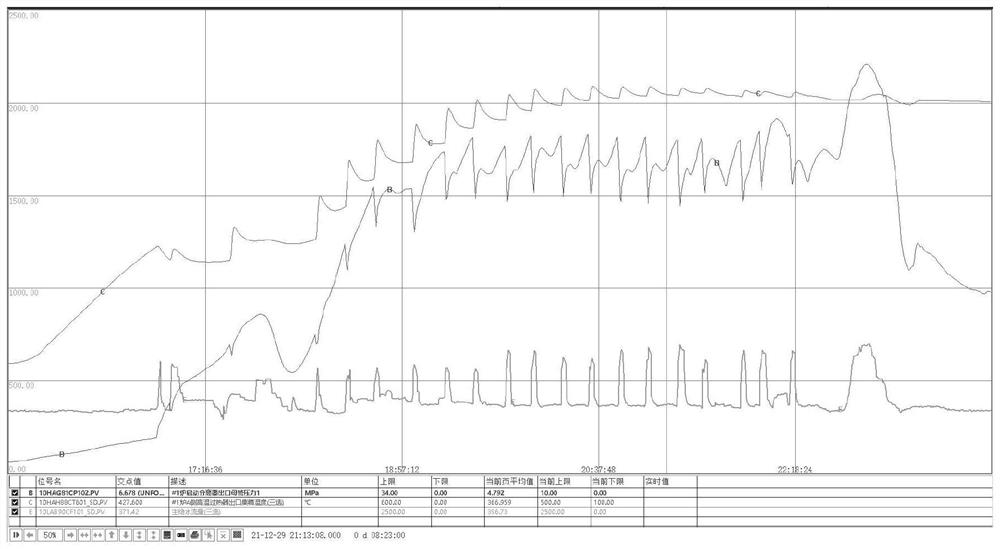

[0068] (1) Increase the water flow rate of the water wall 2. The principle of controlling the flow rate of the water wall 2 is to weaken the vaporization and boosting capacity of the water wall when the once-through boiler blows the pipe, so that the water temperature at the outlet of the separator is always lower than the saturation temperature corresponding to the outlet pressure of the separator. Thereby, the pressure increase rate of the wet steam saturation of the soda-water system is delayed; specifically, in this embodiment, the water flow rate of the water wall 2 is 371.42t / h.

[0069] And the total amount of water supplied by the flushing pipe G fw is 192.53t / h, according to M coal ≈0.15×G fw , the required coal feed is about 28.88t;

[0070] (2) Open the discharge valve 6 of the water storage tank to release the pressure, and control the pressure of the superheater system, so that the outlet pressure of the superheater is always lower than the blowing pipe pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com