Clothes processing device and clothes washing and drying machine

A clothing treatment device and a part of the technology, applied in the field of clothing treatment devices and washing and drying machines, can solve the problems of limited space for the condenser, limited contact area, and low drying efficiency, so as to improve the condensation effect and drying efficiency, The effect of increasing the contact area and increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

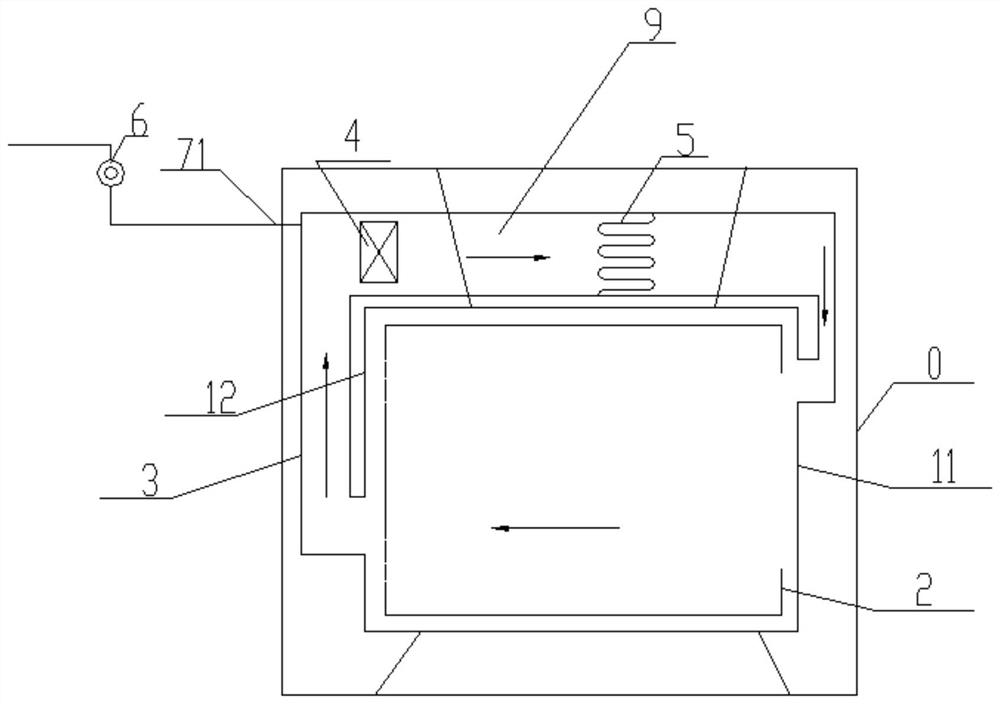

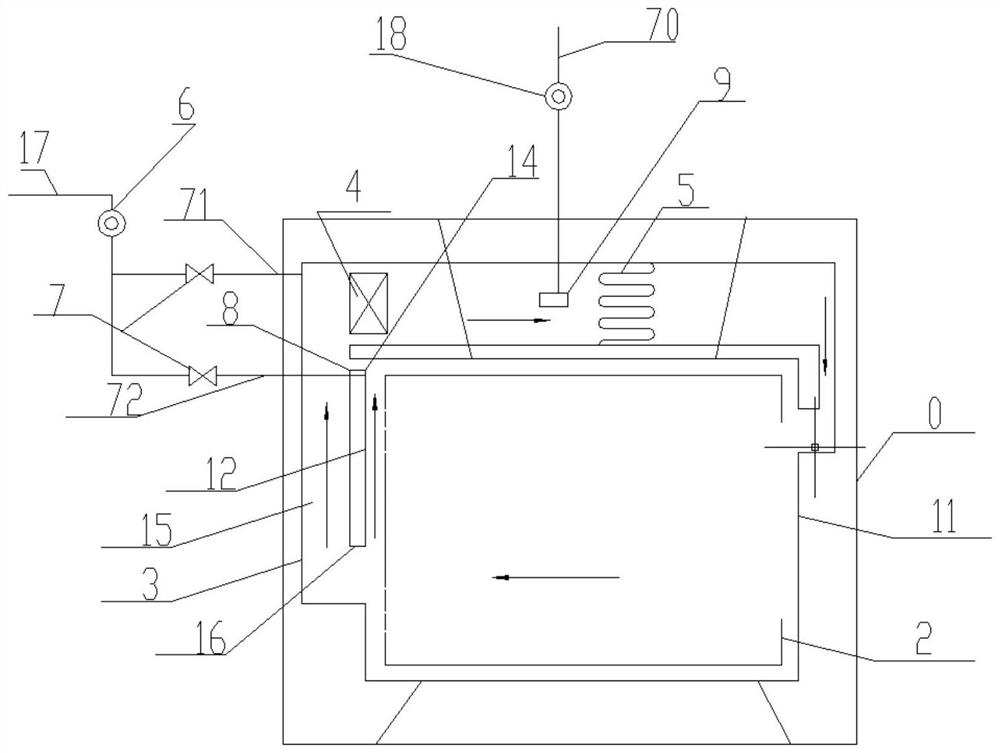

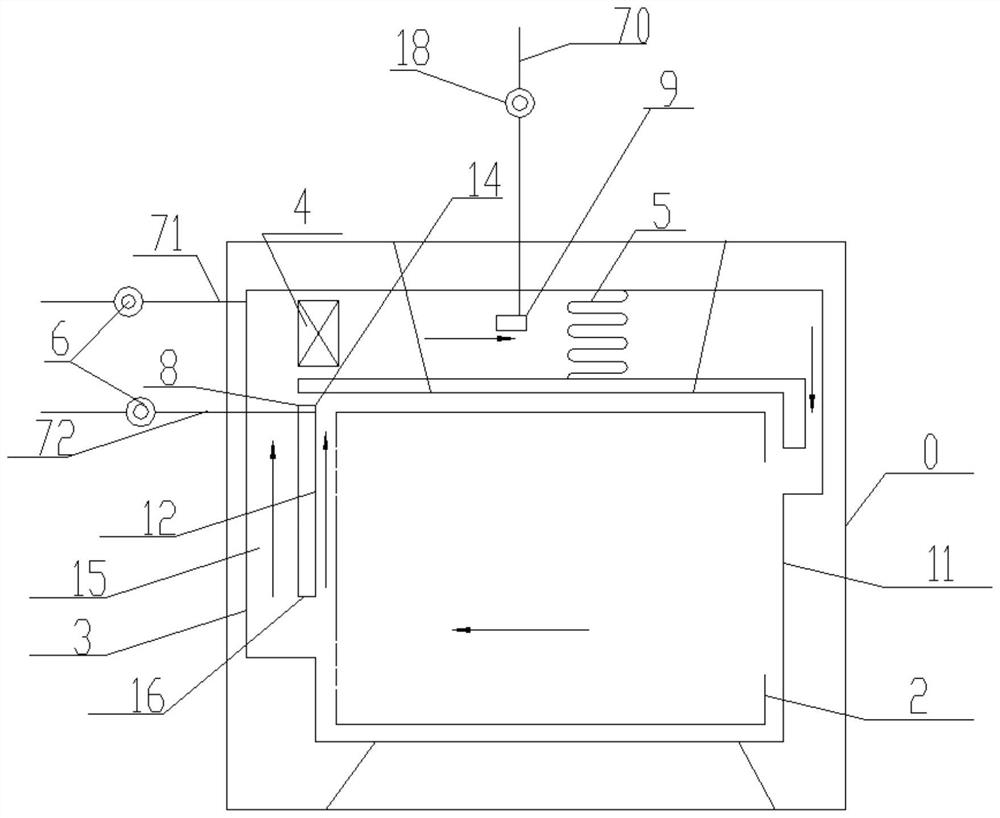

[0039] see figure 1 As shown, the conventional drying technical solution of the existing electric heating laundry washing and drying machine is to form a circulating drying air duct system in the entire box frame 0 . Among them, the entire air circulation path includes the rear cylinder 12, the middle and lower part of the rear cylinder 12 is designed with an air outlet, which is connected to the condenser 3, and a first liquid inlet pipe 71 is designed in the upper part of the condenser 3, so that the low-temperature water in the liquid inlet pipe and the condensate entering The convective flow of the hot and humid air in the heater 3 produces direct and / or indirect contact to achieve heat and mass transfer, resulting in condensation, thereby reducing the temperature and humidity of the hot and humid air. The dry air passes through the circulating fan 4 and then flows through the heater 5 for heating. Then enter the front cylinder 11 and the inner cylinder 2 to heat and evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com