Online carbon black ladle-to-ladle device

A technology of carbon black and reverse packaging, which is applied in packaging, fibrous fillers, etc., can solve the problems of low efficiency and achieve the effects of simple operation, convenient maintenance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

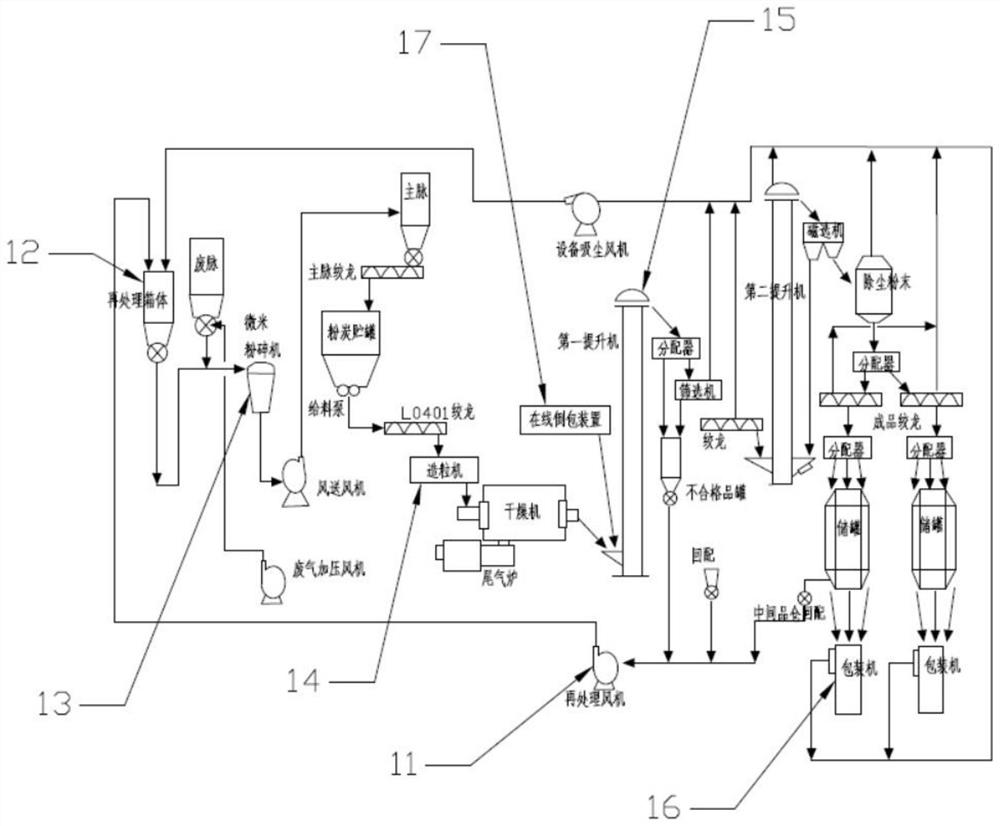

[0036] The present invention will be further described in detail below with reference to the accompanying drawings.

[0037] as attached Figures 1 to 10 As shown, a carbon black on-line dumping device 17 includes a reprocessing fan 11, a reprocessing box 12 connected to the reprocessing fan 11, and a micron pulverizer connected to the reprocessing box 12. 13. The granulator 14 connected with the micron pulverizer 13, the first elevator 15 connected with the granulator 14, the finished product warehouse connected with the first elevator 15, and the finished product a packaging machine 16 connected to the bin;

[0038] An opening is arranged at the bottom of the first elevator 15, and a carbon black on-line repacking device 17 is added; It is composed of a bag-inverting stroke member used to drive the bag-inverting actuator to move; wherein,

[0039] The said bag-reversing execution part is provided with an iron scrap unit for removing ferromagnetic impurities for unqualifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com