Returned material warehouse-in managing system and method for supplier managing stock center

A supplier and inventory technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of increasing the workload of returning materials into the warehouse and increasing the seller's inventory, so as to improve the efficiency of returning materials and reduce inventory Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

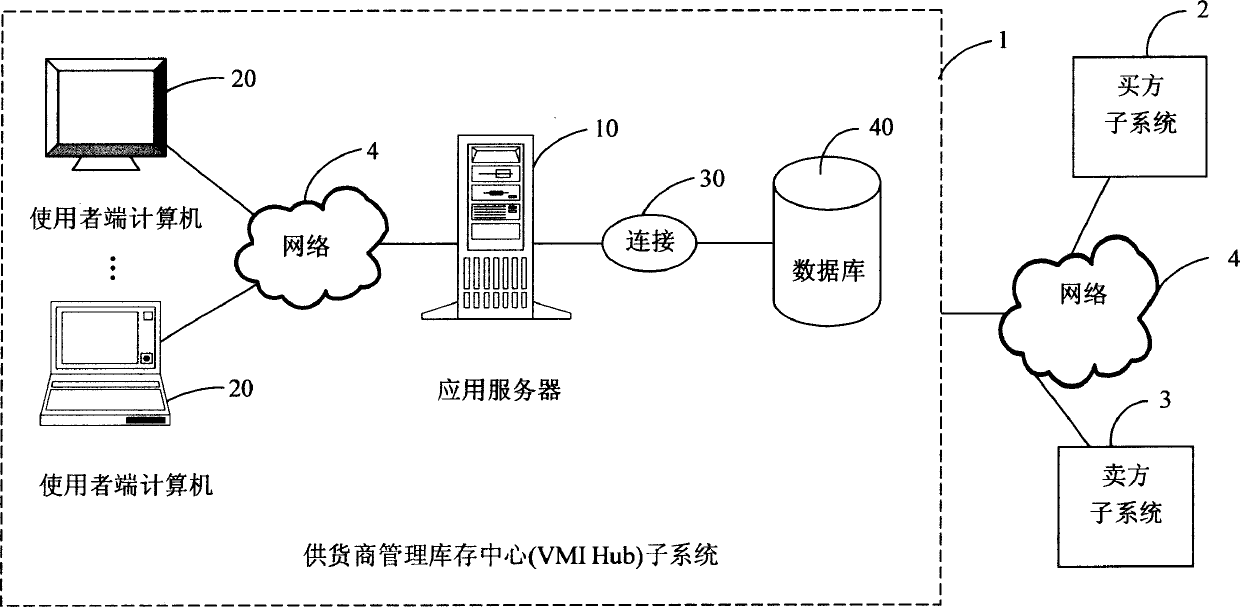

[0024] As shown in FIG. 1 , it is a hardware architecture diagram of the returned material storage control system of the supplier management inventory center of the present invention. The system includes a vendor managed inventory center (Vendor Managed Inventory Hub, VMI Hub) subsystem 1 , a buyer subsystem 2 , a seller subsystem 3 and a network 4 . The aforementioned VMI Hub subsystem 1 , buyer subsystem 2 and seller subsystem 3 are connected through a network 4 . Wherein, the network 4 may be an intranet (Intranet), or the Internet (Internet) or other types of communication networks.

[0025] The VMI Hub subsystem 1 is used to store and manage the goods delivered by the seller subsystem 3, and receive the returned materials delivered by the buyer subsystem 2. The buyer and the seller refer to the relative position of two or more companies with supply and demand relationship in the supply chain, that is, the company (supplier) in the upstream of the supply chain is the sell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com