Anti-yellowing and anti-thick-coating pinhole type hydroxyalkylamide and preparation method thereof

A hydroxyalkyl amide anti-yellowing technology, applied in coatings, powder coatings, polyester coatings, etc., can solve the problems of poor anti-yellowing performance, obvious and serious pinholes on the surface, and achieve long leveling time, Excellent high temperature yellowing resistance, slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

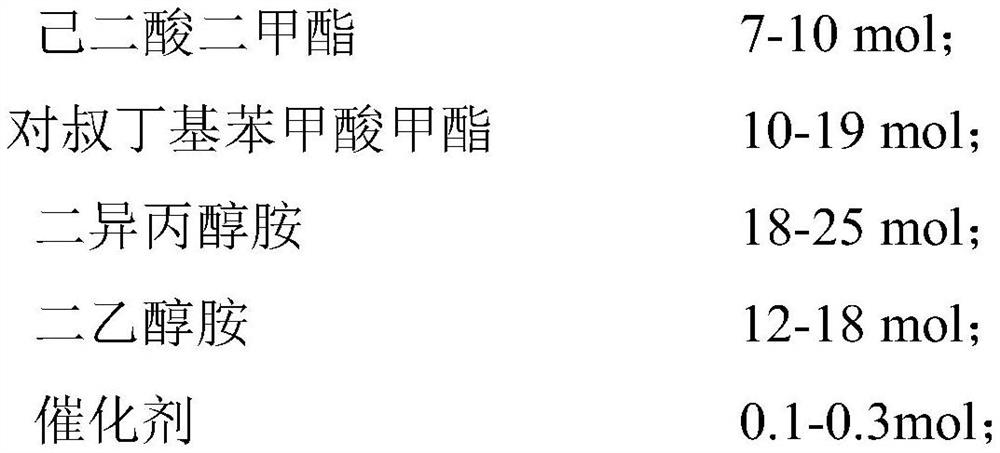

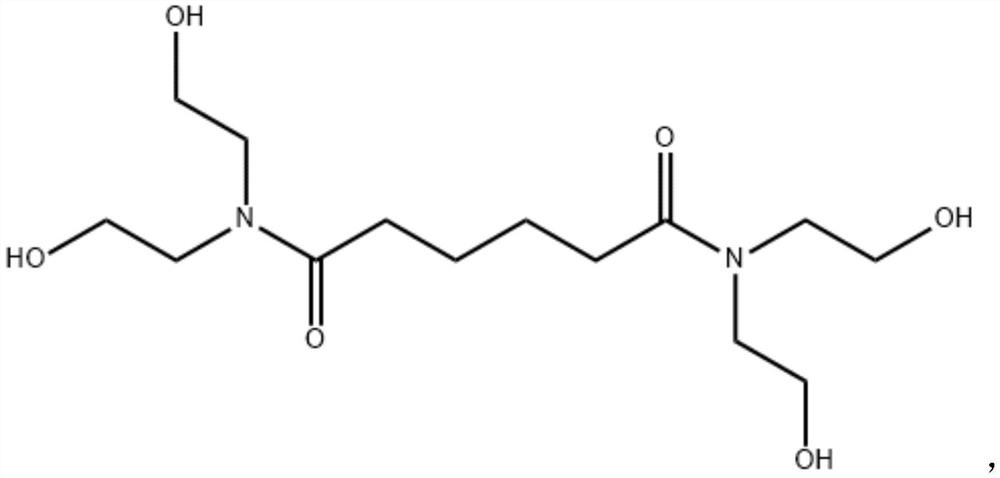

[0039] A preparation method of anti-yellowing and anti-thick-coating pinhole type hydroxyalkylamide; the molar composition of main raw materials comprises:

[0040]

[0041] The crystallization solvent is a mixed solvent of methanol and cyclohexanone, and the molar ratio of the two is 1:3.

[0042] The preparation method includes the following steps:

[0043] A, add methyl para-tert-butyl benzoate, dimethyl adipate respectively in header tank 1 and header tank 2 for subsequent use;

[0044] B. Add the diethanolamine and catalyst of the formula amount into the reaction kettle, after stirring evenly, heat up to 100-115 ° C, then start the vacuum, when the vacuum degree reaches -0.090Mpa to -0.095Mpa, dropwise add the Methyl p-tert-butylbenzoate, and carry out insulation reaction;

[0045] C, when methyl p-tert-butylbenzoate is added dropwise to half of the formula amount, stop the dripping, use vacuum to inhale the diisopropanolamine of the formula amount in the reactor at ...

Embodiment 2

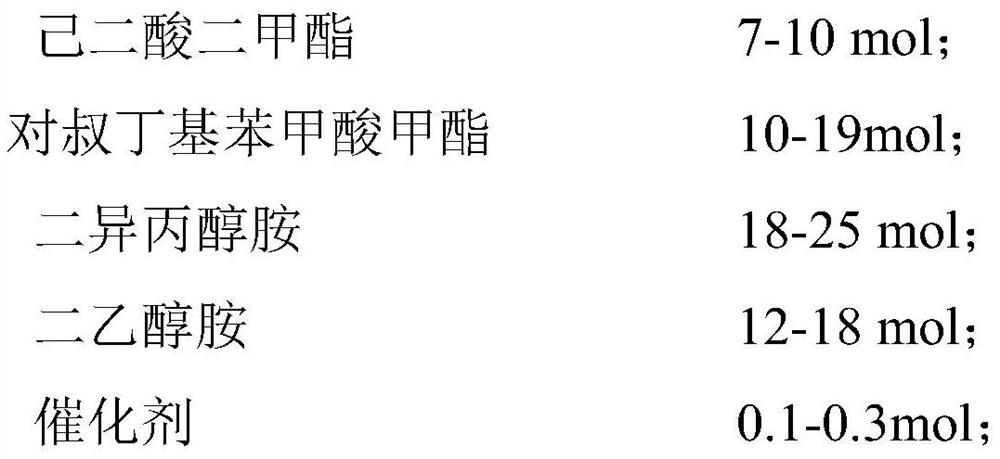

[0052] A preparation method of anti-yellowing and anti-thick-coating pinhole type hydroxyalkylamide; the molar composition of main raw materials comprises:

[0053]

[0054] The crystallization solvent is a mixed solvent of methanol and cyclohexanone, and the molar ratio of the two is 1:3.5.

[0055] The preparation method is the same as in Example 1.

[0056] Prepared product: hydroxyl equivalent: 108 g / mol, yield 95%; average functionality of the prepared product is 3.

Embodiment 3

[0058] A preparation method of anti-yellowing and anti-thick-coating pinhole type hydroxyalkylamide; the molar composition of main raw materials comprises:

[0059]

[0060] The crystallization solvent is a mixed solvent of methanol and cyclohexanone, and the molar ratio of the two is 1:3.

[0061] The preparation method is the same as in Example 1.

[0062] Prepared product: hydroxyl equivalent: 113 g / mol, yield 94%; average functionality of the prepared product is 2.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com